Preparation method of WO3 electrochromic device for automobile film

A technology for electrochromic devices and automotive film, applied in instruments, nonlinear optics, optics, etc., can solve problems such as worrying quality problems, toxic gas harming the health of car owners, and inability to achieve full-featured protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Preparation of electrodeposited WO 3 Precursor solution of electrochromic film: react tungsten powder with hydrogen peroxide to prepare electrodeposited WO 3 Thin film precursor solution, then dilute the prepared solution with absolute ethanol and acetic acid and adjust the pH value.

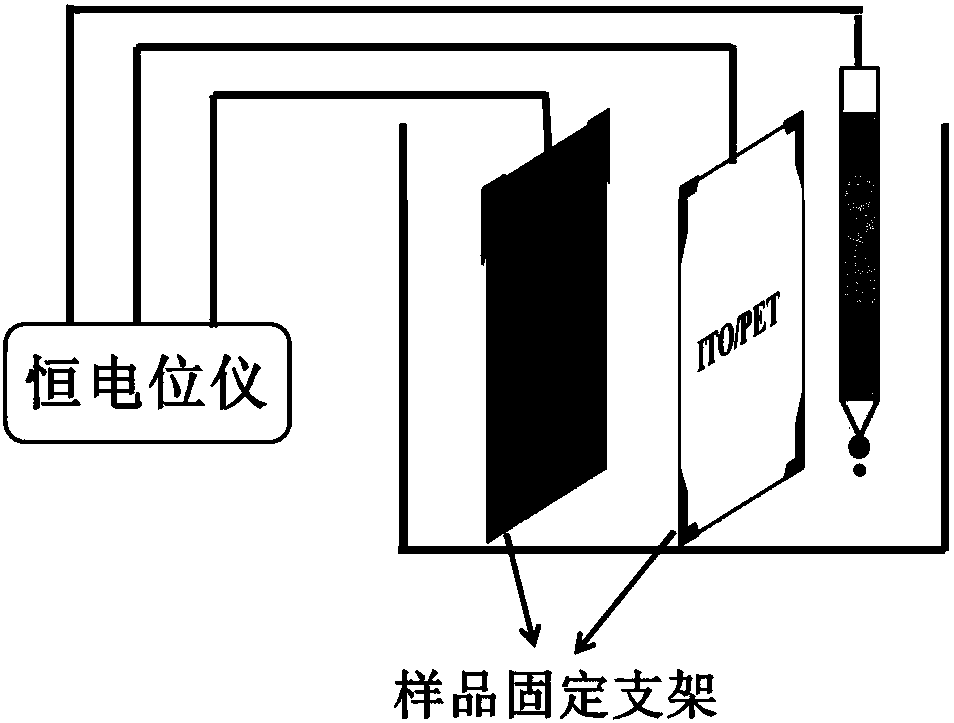

[0025] 2). Deposit WO on ITO / PET substrate 3 Electrochromic thin films: deposited by potentiostat three-electrode system. Select the deposition mode as constant current, and the minimum deposition current density is about 1mA / cm 2 , the deposition time is 300s. At the same time choose to use 5×5cm 2 Electrochromic WO 3Taking the thin film as an example, a graphite electrode of the same size is selected as the counter electrode. Using ITO / PET as the working electrode, the working electrode and the counter electrode are arranged in parallel and symmetrically. At the same time choose Ag / KCl as the reference electrode.

[0026] 3). Dry the deposited film at 80° C. for 5 hours, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com