Preparation method for carbon doped carbon nitride film electrode

A thin-film electrode, carbon nitride technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc. Uniformity, incomplete separation of electrons and holes, etc., to achieve effective separation of electrons and holes, good optoelectronic properties, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

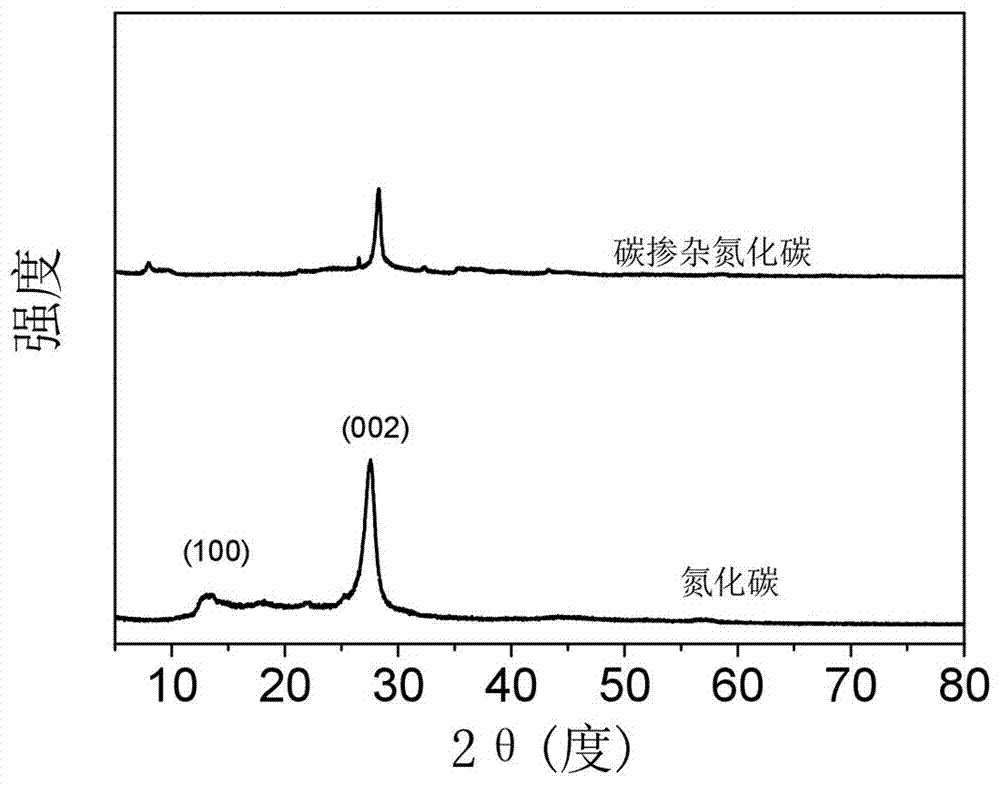

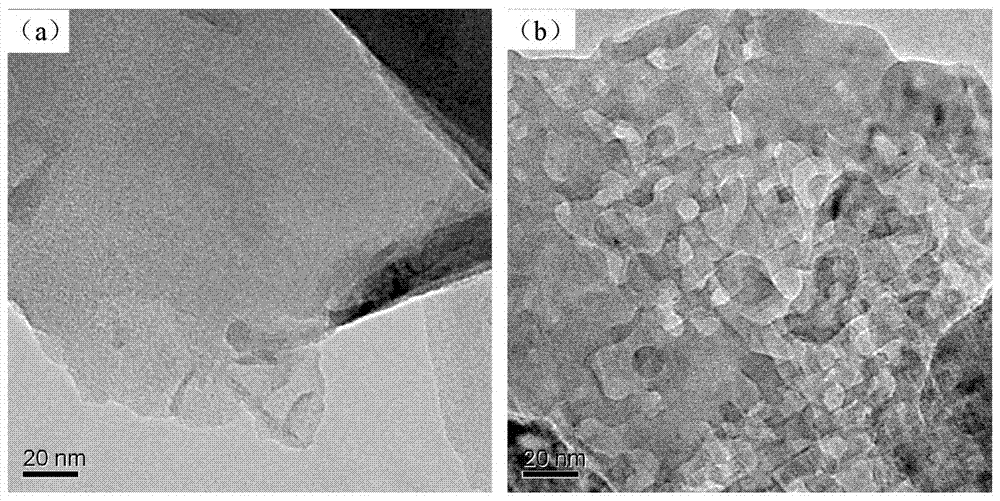

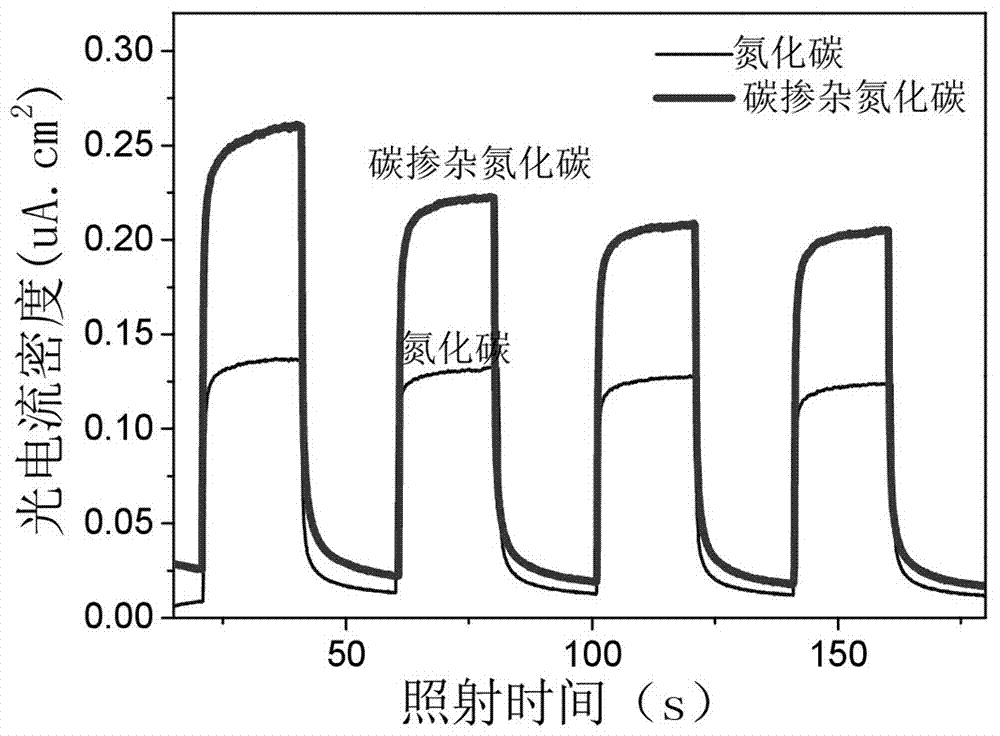

[0034] Embodiment 1: the preparation of carbon-doped carbon nitride film electrode

[0035] A method for preparing a carbon-doped carbon nitride film electrode, comprising the steps of:

[0036] S1, using melamine, cyanuric acid and barbituric acid as raw materials to prepare carbon-doped carbon nitride;

[0037] S1-1. Take 10g of melamine, 10g of cyanuric acid, and 1g of barbituric acid, grind them, dissolve them in 100ml of water, mill them with a speed of 300r / min for 0.5h, stir them for 2h, and dry them on an electric furnace to obtain a precursor body.

[0038] S1-2. Put the precursor in a muffle furnace, heat it up to 550°C at a heating rate of 2.5°C / min, and keep it at 550°C for 4 hours. After natural cooling, take out the block, grind it for 20 minutes, and dissolve it with water and ethanol respectively. Rinse 3 times, filter, and dry at 80°C for 12 hours to obtain porous carbon-doped carbon nitride.

[0039] S2. Dissolving the carbon-doped carbon nitride obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com