Organic fertilizer

A technology of organic fertilizers and raw materials, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as environmental pollution and achieve the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

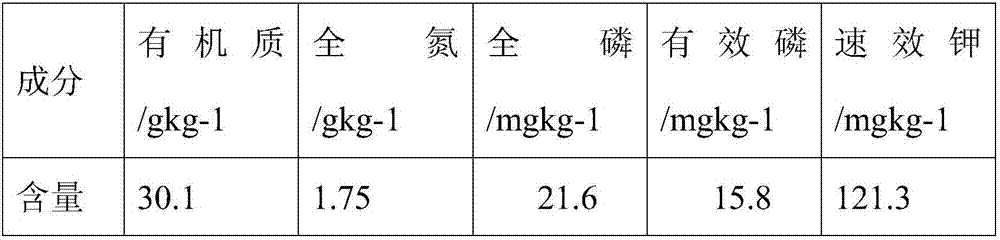

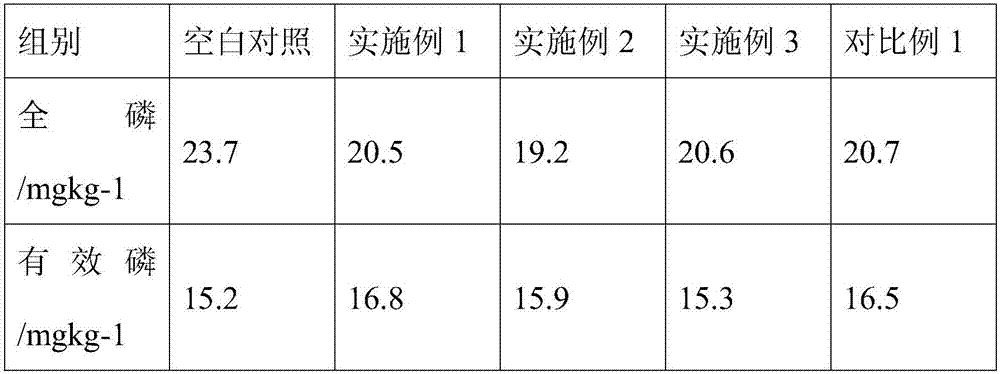

Embodiment 1

[0023] An organic fertilizer, the organic fertilizer has the following raw materials in parts by weight: 30 parts of mixed residue from a traditional Chinese medicine factory, 10 parts of mixed tail water from a traditional Chinese medicine factory, 1 to 5 parts of urea, 2 to 5 parts of phosphorus pentoxide, and 10 to 5 parts of pig manure 15 parts, 1 to 5 parts of copper sulfate, 1 to 3 parts of boric acid, 1 to 300 million Bacillus phospholyticus / ml, and 1 part of calcium silicate.

[0024] A kind of preparation method of organic fertilizer, the preparation of described organic fertilizer comprises the following steps: (1) the activation of Bacillus megaterium phospholyticum:

[0025] A. Take 1g of Bacillus megaterium phosphate solubilizer and mix it with 80mL of water to obtain the inoculum solution; B. Put the mixed residue of the Chinese medicine factory, the mixed tail water of the Chinese medicine factory, and pig manure in the fermentation device, and add the inoculated...

Embodiment 2

[0030] An organic fertilizer, the organic fertilizer has the following raw materials in parts by weight: 50 parts of mixed residue from a Chinese medicine factory, 20 parts of mixed tail water from a Chinese medicine factory, 5 parts of urea, 5 parts of phosphorus pentoxide, 15 parts of pig manure, 5 parts of copper sulfate 3 parts, 3 parts of boric acid, 300 million Bacillus phosphate solubilizers / ml, 3 parts of silicic acid cap.

[0031] A kind of preparation method of organic fertilizer, the preparation of described organic fertilizer comprises the following steps:

[0032] (1) Activation of Bacillus megaterium phospholyticum:

[0033] A. Take 1g of Bacillus megaterium phosphate solubilizer and mix it with 120mL of water to obtain the inoculum solution; B. Put the mixed residue of the Chinese medicine factory, the mixed tail water of the Chinese medicine factory, and pig manure in the fermentation device, and add the inoculated strain to carry out accumulation fermentation ...

Embodiment 3

[0038] An organic fertilizer has the following raw materials in parts by weight: 40 parts of mixed residue from a Chinese medicine factory, 15 parts of mixed tail water from a Chinese medicine factory, 3 parts of urea, 3.4 parts of phosphorus pentoxide, 13 parts of pig manure, 3.1 parts of copper sulfate, and 3 parts of boric acid , Bacillus megaterium phosphate solubilizer 210 million / ml, calcium silicate 2 parts.

[0039] A kind of preparation method of organic fertilizer, the preparation of described organic fertilizer comprises the following steps:

[0040] (1) Activation of Bacillus megaterium phospholyticum:

[0041] A. Take 1g of Bacillus megaterium phosphate solubilizer and mix it with 100mL of water to obtain the inoculum solution; B. Put the mixed residue of the Chinese medicine factory, the mixed tail water of the Chinese medicine factory, and pig manure in the fermentation device, and add the inoculated strain to carry out accumulation fermentation , the fermentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com