Module drilling machine optimal and fast casing running technical method

A casing and drilling rig technology, applied in the field of casing running, can solve problems such as the occupation of cranes and operators, the long static time of the downhole casing string, and the impact on the efficiency of making up, etc., so as to reduce the labor cost and equipment cost. Conducive to operation construction and underground safety, reducing operation time and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

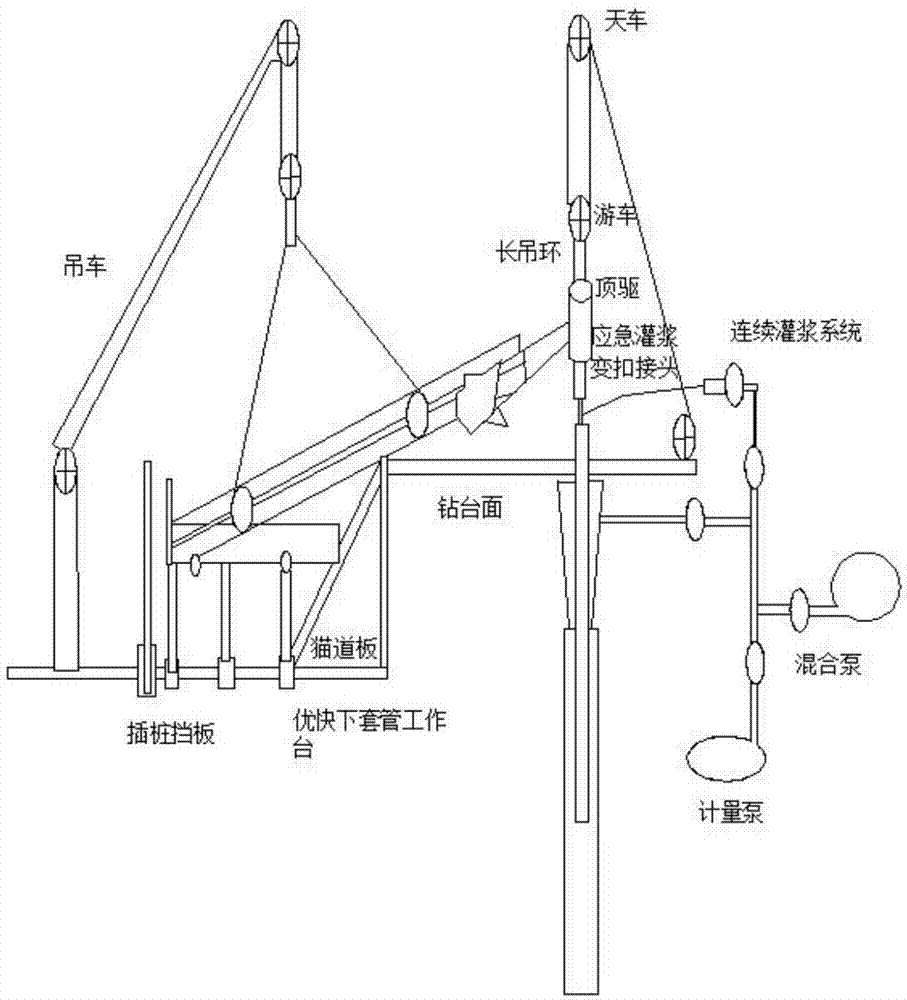

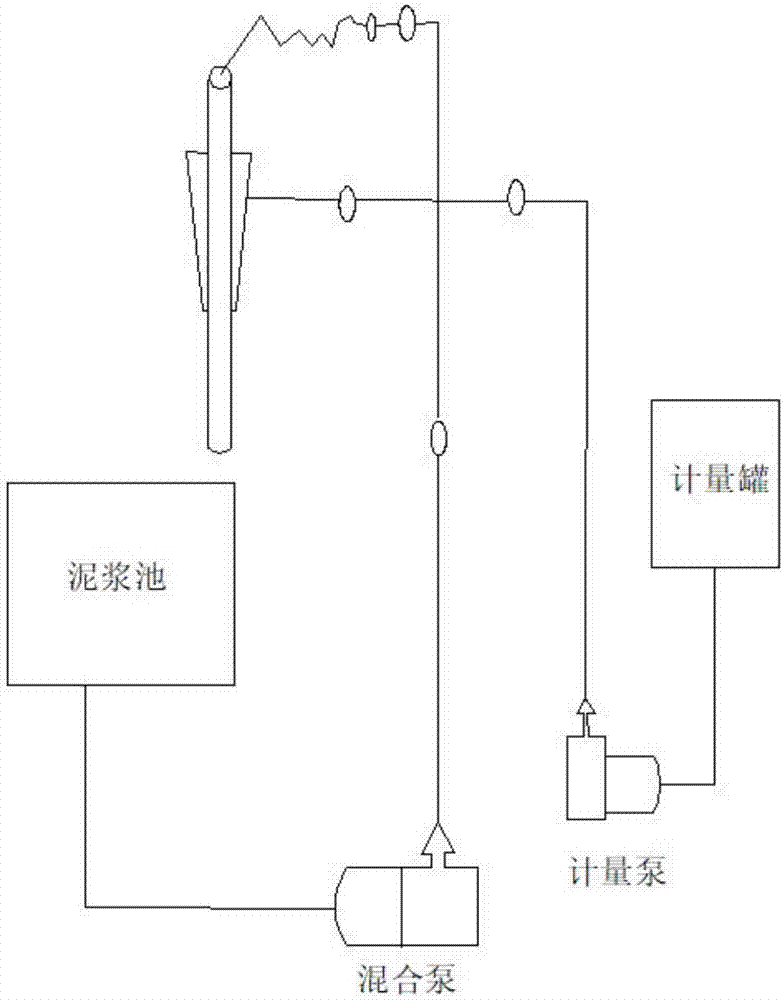

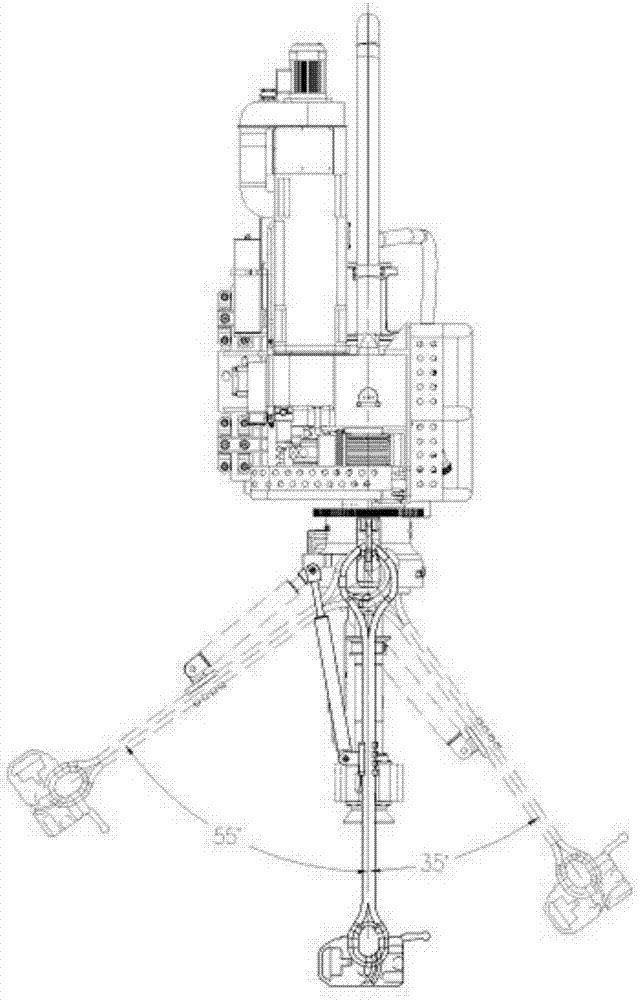

[0060] Reference Figure 1-5 , A technical method for optimal and fast casing running of modular drilling rigs, which is different from conventional workover rigs and drilling platform cranes combined with dual pneumatic drawworks for casing running. The main steps include:

[0061] S1: Choose long-size hoist rings for top drive hoist before drilling and completion;

[0062] S2: Lay out the casing pipe and the pipe deck sleeper area, and make the casing table by serial numbering;

[0063] S3: Put the excellent fast casing running table in place;

[0064] S4: Connect the continuous grouting pipeline; use a crane to hoist multiple casings to the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com