Planar passive type micromixer with stepped passages and I-shaped baffles

A ladder-shaped mixer technology, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of difficult mixing and low flow Reynolds number, and achieve increased contact area, improved mixing effect, and fluid velocity increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A flat passive micro-mixer with a stepped channel processing glyph baffle is made of polydimethylsiloxane silicone. The channel structure pattern transfer and polydimethylsiloxane are first realized on the monocrystalline silicon wafer by injection molding. The oxane is cured, and then the cured polydimethylsiloxane is separated from the silicon wafer. Perforation is made on the cured polydimethylsiloxane according to the position of the relative entrance and exit of the channel, and the cured polydimethylsiloxane base plate is irreversibly bonded with the cured polydimethylsiloxane through a corona machine, so that the micromixer channel is completely closed. Finally, install the interface at the three hole positions reserved on the cured polydimethylsiloxane, and complete the preparation for the test piece packaging after connecting the plastic pipe.

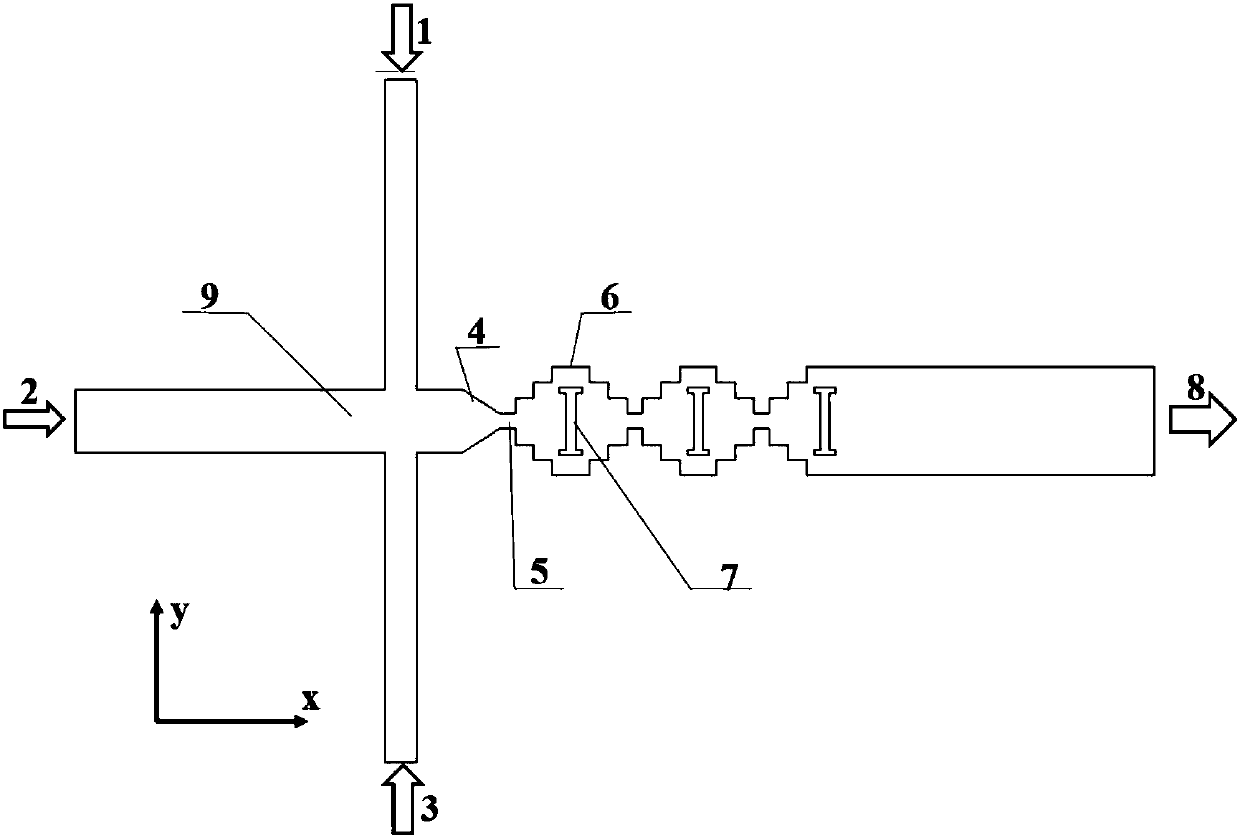

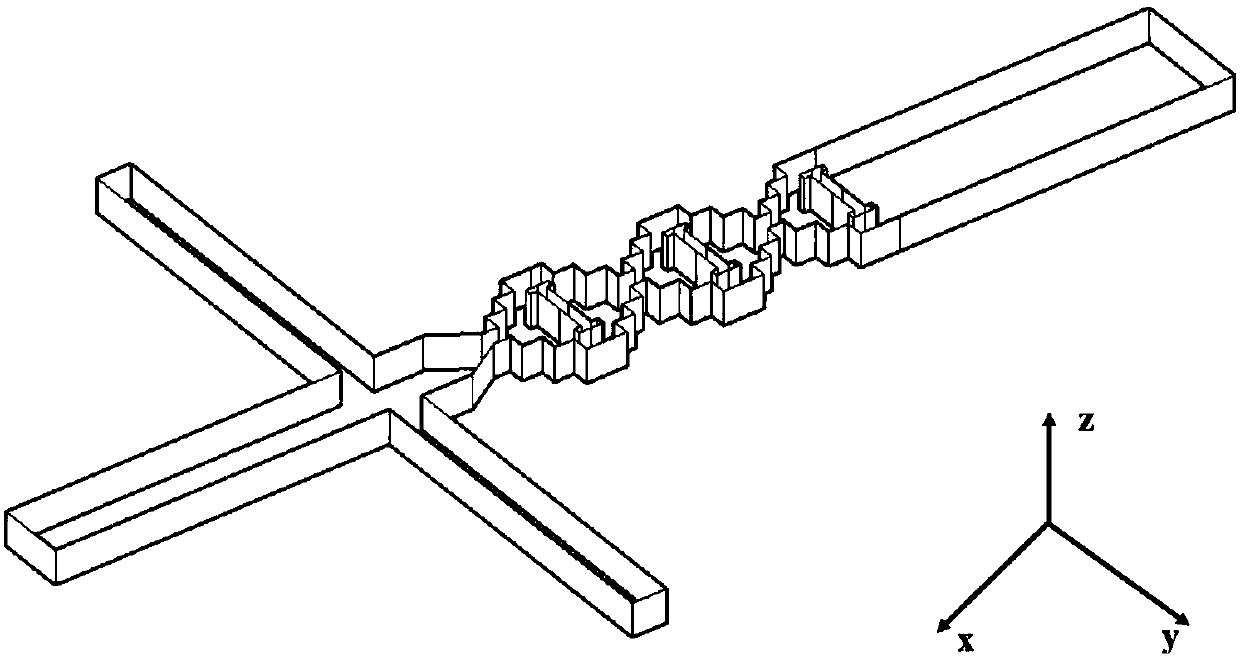

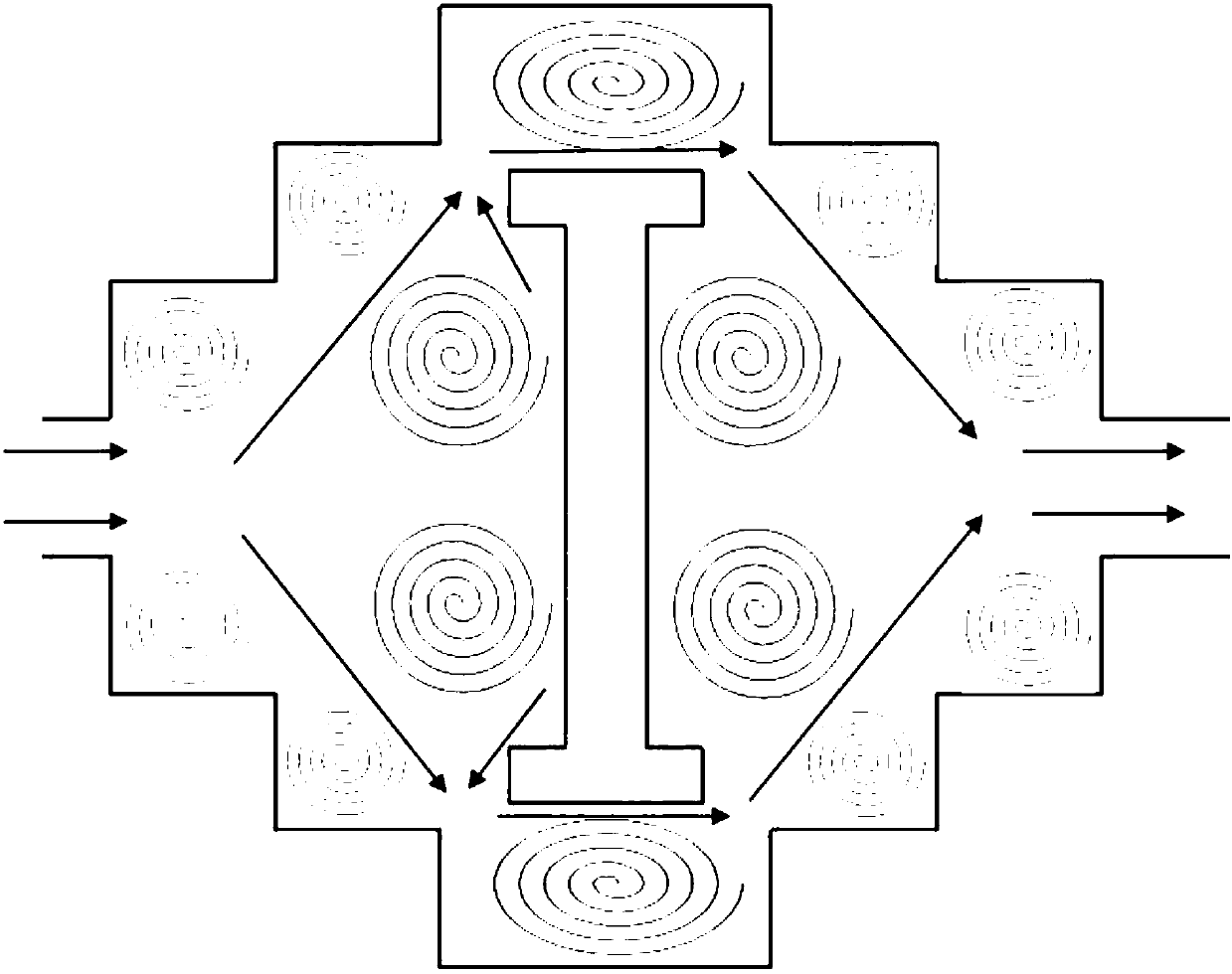

[0022] Such as figure 1 The shown plane passive micromixer with a stepped channel processing font-shaped baffle is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com