Snow removal method of snow remover for clearing accumulated snow at bottom before overhaul of CRH trains

A technology for snow removal vehicles and EMUs, which is applied in the direction of vehicle cleaning, railway car body parts, vehicle cleaning equipment, etc. It can solve the problems of no recovery of melted snow water, water accumulation in snow removal vehicles, and inconvenient use, so as to reduce manual labor intensity , Increased working water volume and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

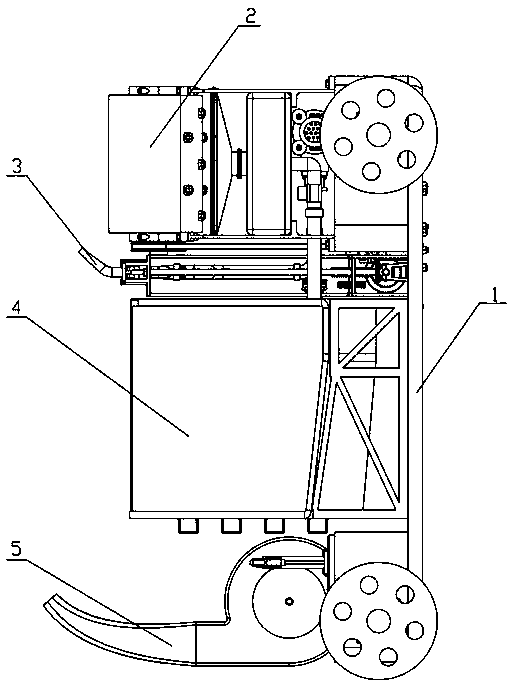

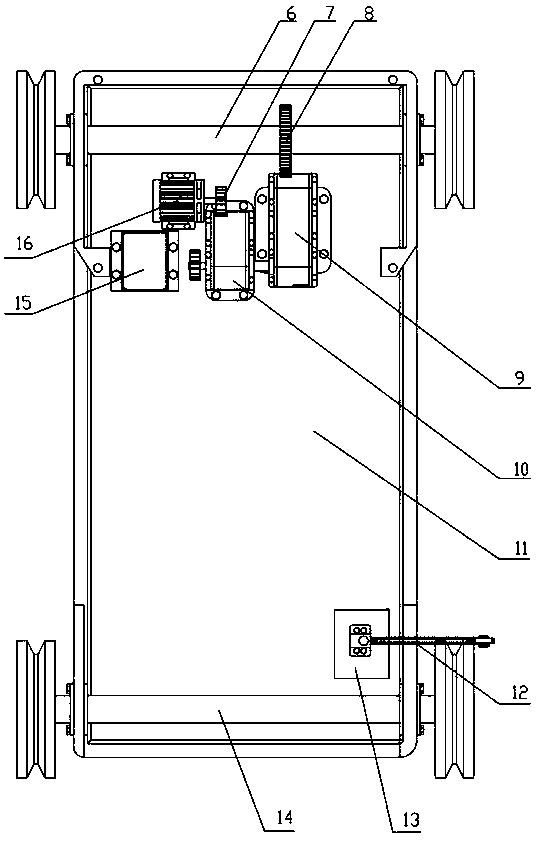

[0037] Embodiment 1: a kind of snow removal method for the snow removal vehicle that is used for clearing the bottom snow accumulation before the EMU overhaul, its main work flow is as follows Figure 8 Shown: When the operator turns on the power, the water in the water tank starts to preheat, the operator presses the start switch of the snow plow truck, the whole vehicle circuit system of the snow plow truck is energized, the chassis transmission and power system (1), the snow melting recovery and reuse system ( 2), the hot water snow removal system (3), the hot water heating and storage system (4), and the hot air blower (5) all start to work, the current receiver (12) receives the current from the track, and passes through the transformer box (13) The electric energy is delivered to the electric motor (16), the hot air blower (5) and the heating wire (17). The electric motor (16) drives the chassis transmission and power system (1), the snow melting recovery and reuse syste...

Embodiment 2

[0038] Embodiment 2: as preferred scheme, on the basis of embodiment 1, as Figure 9 Shown is the work flow of intelligent water valve, can add intelligent water valve switch on the pipeline B (28) that temporary storage tank (27) connects water tank (22), water level sensor is installed inside the water tank, detects the water level of water tank. An embedded microcontroller is installed on the outer shell of the water tank to control the switch of the intelligent water valve according to the detection signal of the water level sensor to prevent the water in the water tank (22) from flowing backwards. When the melted ice and snow fall to the snowmelt recovery and reuse system (2), the water level in the water tank rises. When the water level is lower than the temporary water storage tank, the smart water valve opens, and the water in the temporary water storage tank flows back to the water tank. When the water in the water tank When the water level is higher than the temporar...

Embodiment 3

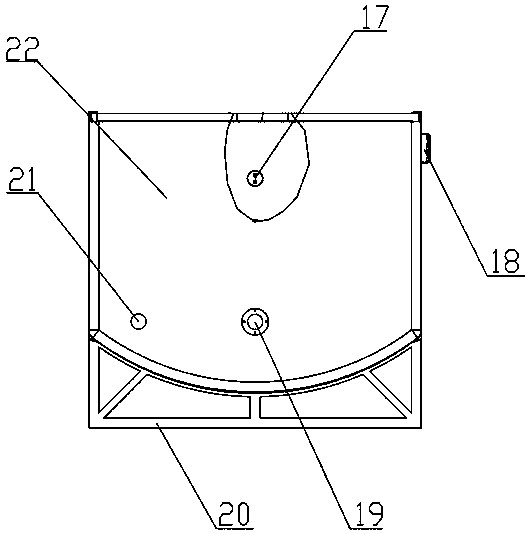

[0040] Embodiment 3: A snow removal method for snow removal vehicles used to remove snow at the bottom before maintenance of EMUs, its work flow is as follows Figure 11-12 Shown: Figure 11 To control the tempering workflow, Figure 12 Based on the overall control principle of the snow removal vehicle, on the basis of Embodiment 1, the hot water heating system (4) can install a temperature sensor inside the water tank (22) to detect the water temperature, a water level sensor to detect the water level, and install a display screen outside the water tank to display the water temperature , water level, control the power of the heating wire and the output of the display screen through the embedded microcontroller of the water tank, realize the functions of adjusting the water temperature and real-time viewing of the water level and water temperature, and connect to the master microcontroller through the control bus, the master controller and the water pump (43 ), the switch ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com