Potassium-salt-ore filling material capable of being pumped at long distance and preparation method of filling material

A long-distance, potash mine technology, applied in the fields of filling, mining equipment, earthwork drilling, etc., can solve problems such as the change of the flow performance of the filling material with time, achieve good economic and social benefits, save costs, The effect of reducing economic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

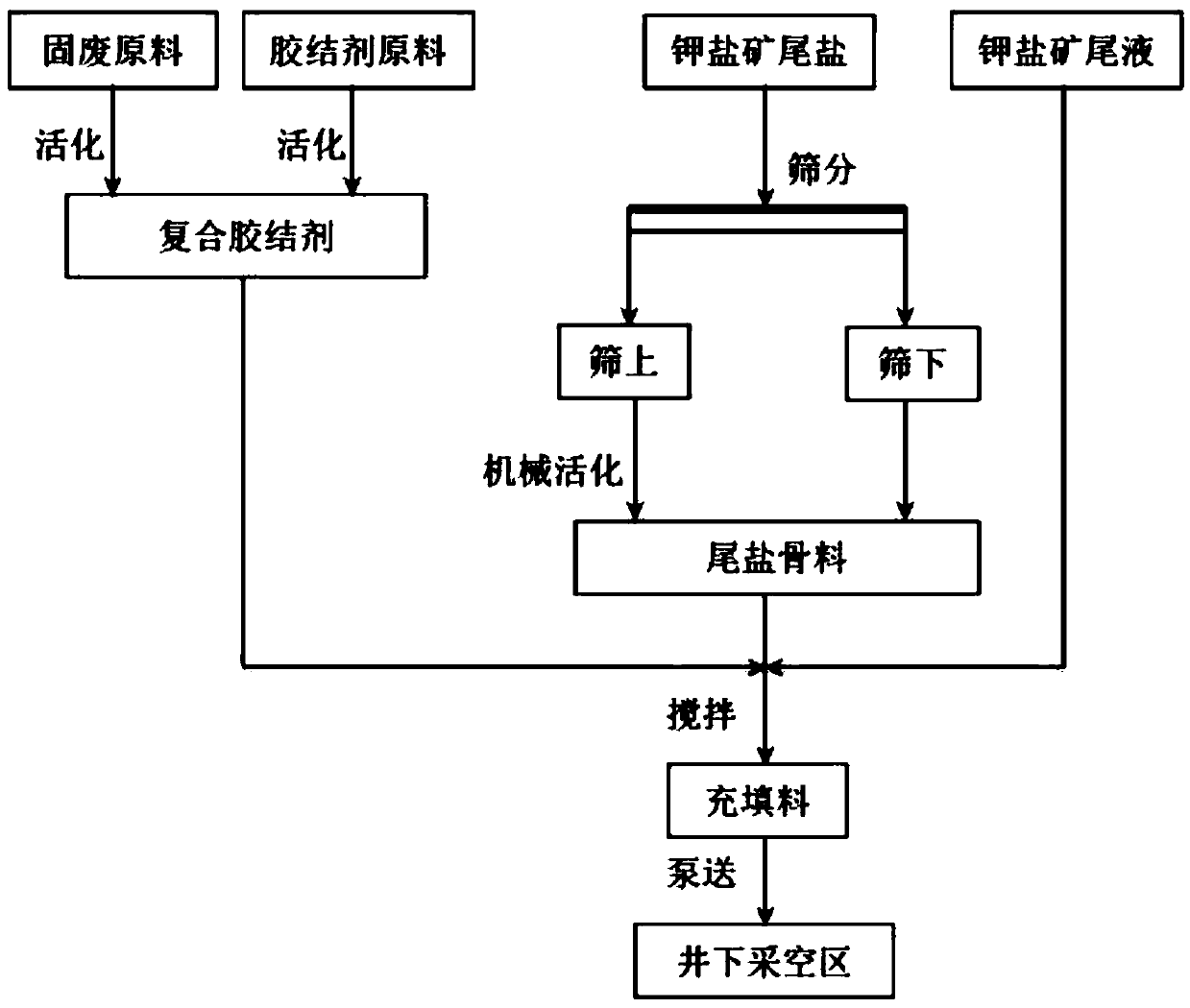

Method used

Image

Examples

Embodiment 1

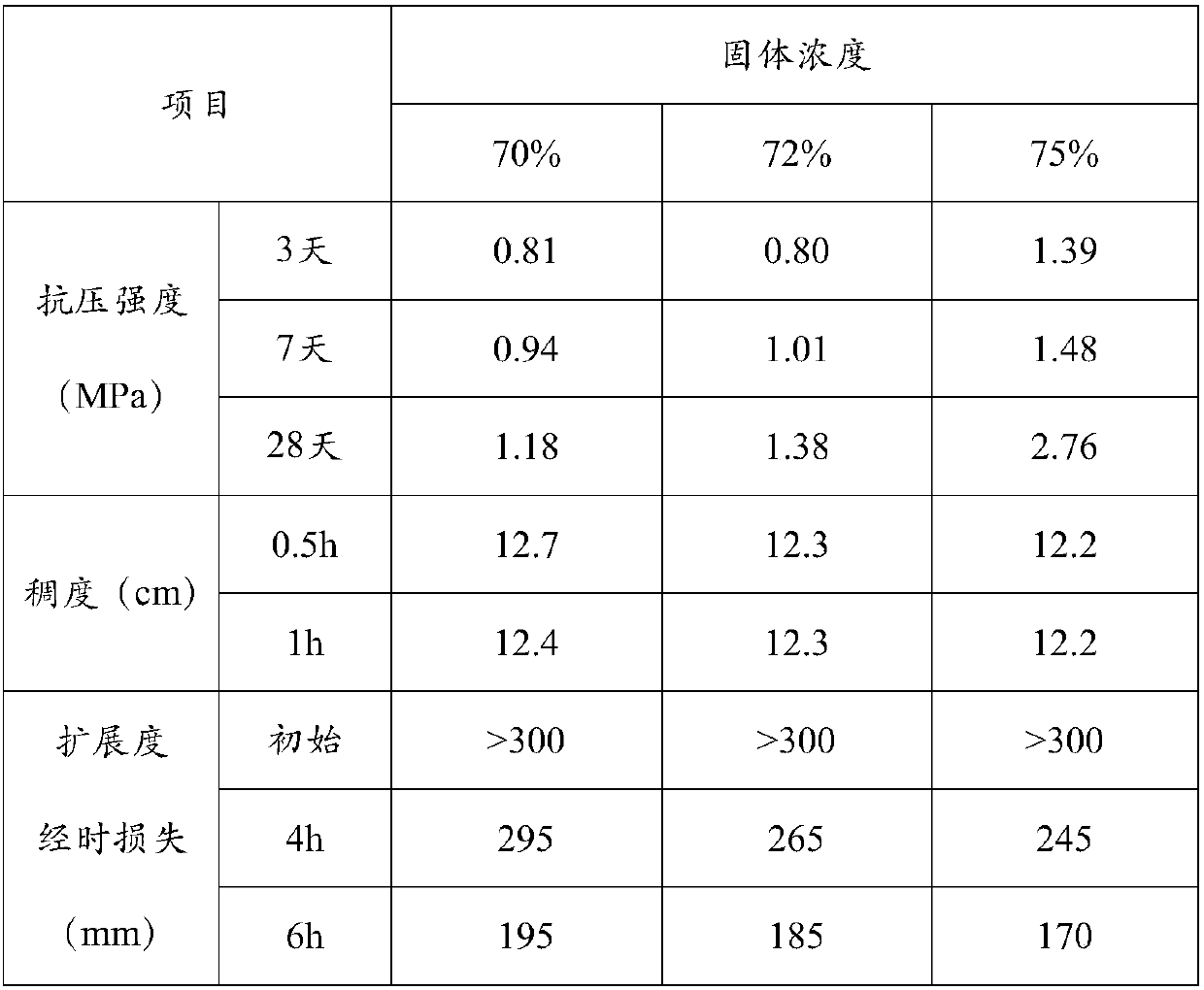

[0028] Activate the steel slag and dolomite with a moisture content below 1%, and grind the steel slag to a specific surface area of 460m 2 / kg, the calcination condition of dolomite is calcination temperature 1000 ℃, holding time 8h, the calcined dolomite is ground to -100 mesh content 50%, the steel slag powder and dolomite are mixed evenly according to the ratio of 4:1, obtained cement. After sieving and grinding, the tail salt aggregate has two particle size ranges of +2.5mm and -2.5mm, the weight ratio is 1:1, and the fineness of the fine powder is -100 mesh, accounting for 50%. Under the condition that the amount of cement is 10%, the filling materials with solid concentrations of 70%, 72%, and 75% are configured respectively, and the measured performance parameters are shown in Table 1.

[0029] Main performance indicators of potassium salt ore filling material in Table 1 Example 1

[0030]

Embodiment 2

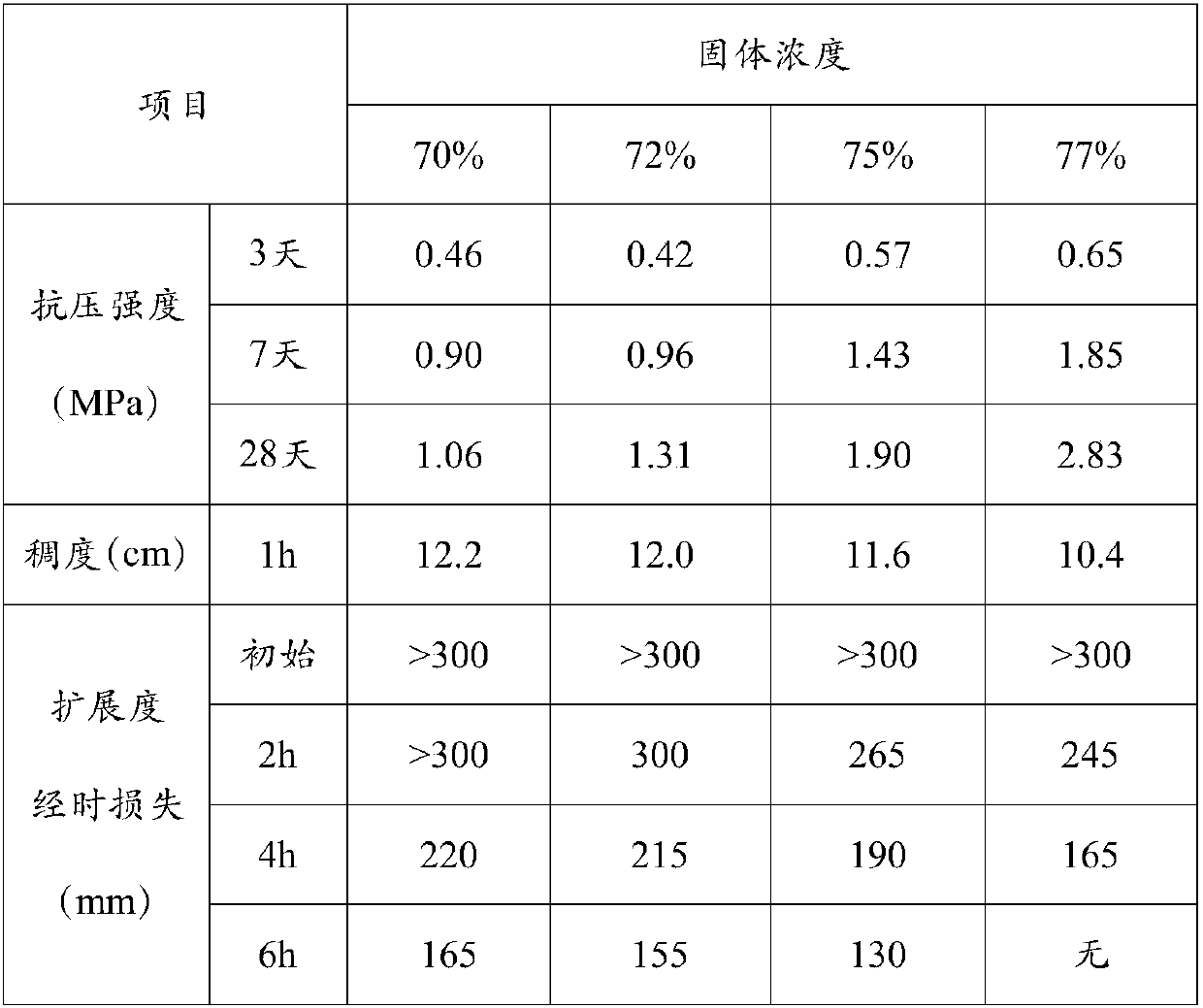

[0032] The steel slag, fly ash, and blast furnace slag with a moisture content below 1% are mechanically ground and activated in equal proportions, and are respectively ground to a specific surface area of 460m 2 / kg, the calcining condition of dolomite is calcining temperature 1000 ℃, holding time 8h, the dolomite after calcining is ground to -100 mesh content 50%, steel slag powder, fly ash, slag, dolomite are pressed 1.9:1.9: Mix evenly at a ratio of 1.9:1 to make a cement. After sieving and grinding, the tail salt aggregate has two particle size ranges of +2.5mm and -2.5mm, the weight ratio is 1:1, and the fineness of the fine powder is -100 mesh, accounting for 50%. Under the condition that the amount of cement is 10%, the fillers with solid concentrations of 70%, 72%, 75%, and 77% are prepared respectively. The measured performance parameters are shown in Table 2.

[0033] Potash salt ore filling main performance index in table 2 embodiment 2

[0034]

Embodiment 3

[0036] The steel slag, calcium carbide slag, and red mud with a moisture content below 1% are mechanically ground and activated at a ratio of 4:1:1, and are respectively ground to a specific surface area of 500m 2 / kg, the calcination conditions of light-burned magnesia are calcination temperature 600°C, holding time 10h, the calcined magnesia is ground to -100 mesh content 50%, steel slag powder, carbide slag, red mud, light-burned magnesia are pressed The ratio of 4:1:1:1.5 is mixed evenly to prepare the cement. After sieving and grinding, the tail salt aggregate has two particle size ranges of +2.5mm and -2.5mm, the weight ratio is 1:1, and the fineness of the fine powder is -100 mesh, accounting for 50%. When the total amount of composite cement is 7.5%, 5%, and 2.5%, they are respectively configured as filling materials with solid concentrations of 70% and 75%. The measured performance parameters are shown in Table 3.

[0037] Key performance indicators of potassium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com