Porous ceramic material with high water absorption rate and high water retention rate and preparation method and application thereof

A technology of porous ceramics and water retention rate, which is applied to the formulation and application of ceramic products and perfume preparations, can solve the problems of temporary use only, weak water retention, poor water retention performance, etc., and achieves a simple and efficient preparation method. The effect of improving water retention and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

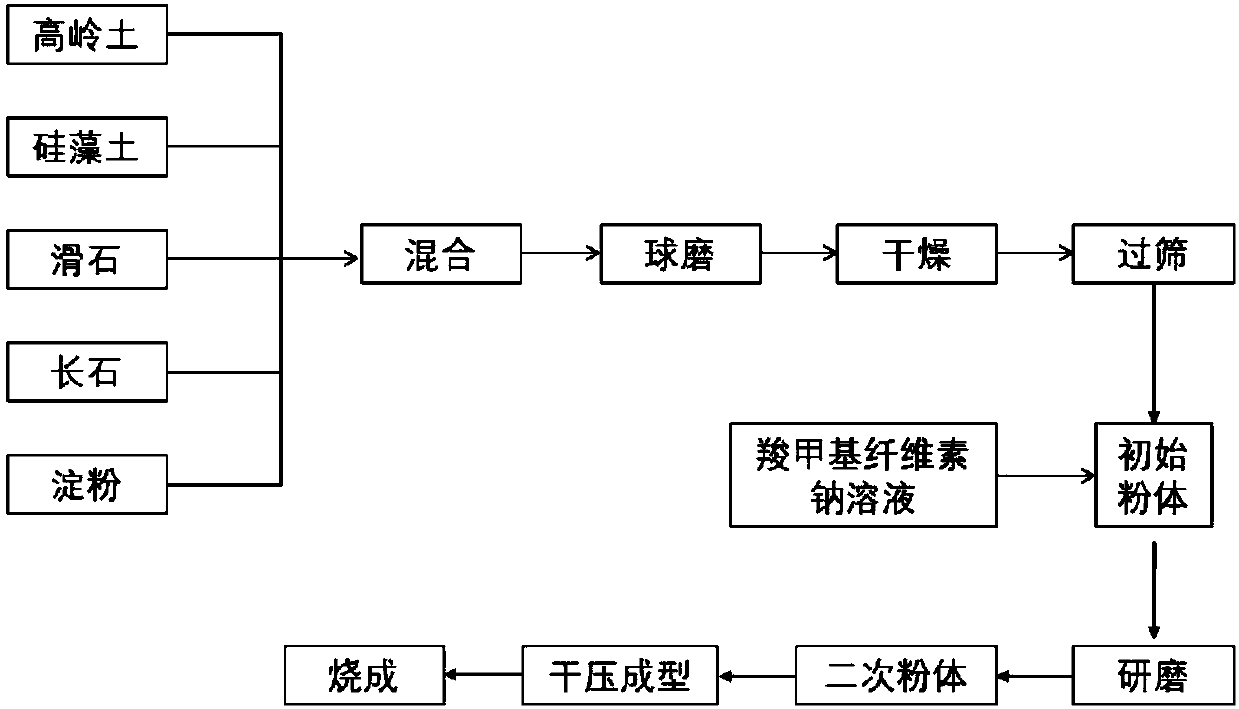

[0034] A method for preparing a porous ceramic material with high water absorption rate and high water retention rate, comprising the following steps:

[0035] (1) Mix kaolin, feldspar, talc, diatomaceous earth and starch according to the mass ratio of 6:4:1:12:2, put them into a ball mill and mill them for 20 minutes (rotating speed is 300r / min), and dry (dry The temperature is 100°C, the time is 1h), and the initial powder is obtained by passing through a 60-mesh sieve;

[0036] (2) Take 3g of sodium carboxymethyl cellulose solution with a concentration of 20g / L and evenly drop it into 125g of the initial powder in step (1), grind for 0.5h, and mix the powder and sodium carboxymethyl cellulose solution evenly , through a 60-mesh sieve to obtain a secondary powder;

[0037] (3) Dry press the secondary powder of step (2) under 20MPa pressure (molding time is 3min), and then sinter at 1100°C (sintering time is 30min) to obtain a powder with high water absorption rate High wat...

Embodiment 2

[0040] A method for preparing a porous ceramic material with high water absorption rate and high water retention rate, comprising the following steps:

[0041] (1) Mix kaolin, feldspar, talc, diatomaceous earth and starch according to the mass ratio of 5:3:1:12:3, put them into a ball mill for 10 minutes (rotating speed is 250r / min), and dry (dry The temperature is 100°C, the time is 1h), and the initial powder is obtained by passing through a 60-mesh sieve;

[0042] (2) Take 2g of sodium carboxymethyl cellulose solution with a concentration of 20g / L and evenly drop it into 120g of the initial powder in step (1), grind for 0.5h, and mix the powder and sodium carboxymethyl cellulose solution evenly , through a 60-mesh sieve to obtain a secondary powder;

[0043] (3) Dry press the secondary powder of step (2) under 30MPa pressure (molding time is 3min), and then sinter at 1100°C (sintering time is 30min) to obtain a powder with high water absorption rate and high water retentio...

Embodiment 3

[0046] A method for preparing a porous ceramic material with high water absorption rate and high water retention rate, comprising the following steps:

[0047] (1) Mix kaolin, feldspar, talc, diatomaceous earth and starch according to the mass ratio of 6:3:1:12:3, put them into a ball mill for 10 minutes (rotating speed is 300r / min), and dry (dry The temperature is 100°C, the time is 0.5h), and the initial powder is obtained by passing through a 30-mesh sieve;

[0048] (2) Take 2g of sodium carboxymethyl cellulose solution with a concentration of 20g / L and evenly drop it into 125g of the initial powder in step (1), grind for 0.5h, and mix the powder and sodium carboxymethyl cellulose solution evenly , through a 30-mesh sieve to obtain a secondary powder;

[0049] (3) Dry press the secondary powder of step (2) under a pressure of 20 MPa (molding time is 3 minutes), and then sinter at 1050°C (sintering time is 30 minutes), to obtain a powder with high water absorption rate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com