High-temperature-resistant dual-component polyurethane adhesive for air filter and preparation method of high-temperature-resistant dual-component polyurethane adhesive

A two-component polyurethane and air filter technology, used in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problem of low bonding strength, slow curing speed and high temperature resistance. Insufficient and other problems, to achieve the effect of excellent bonding performance, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

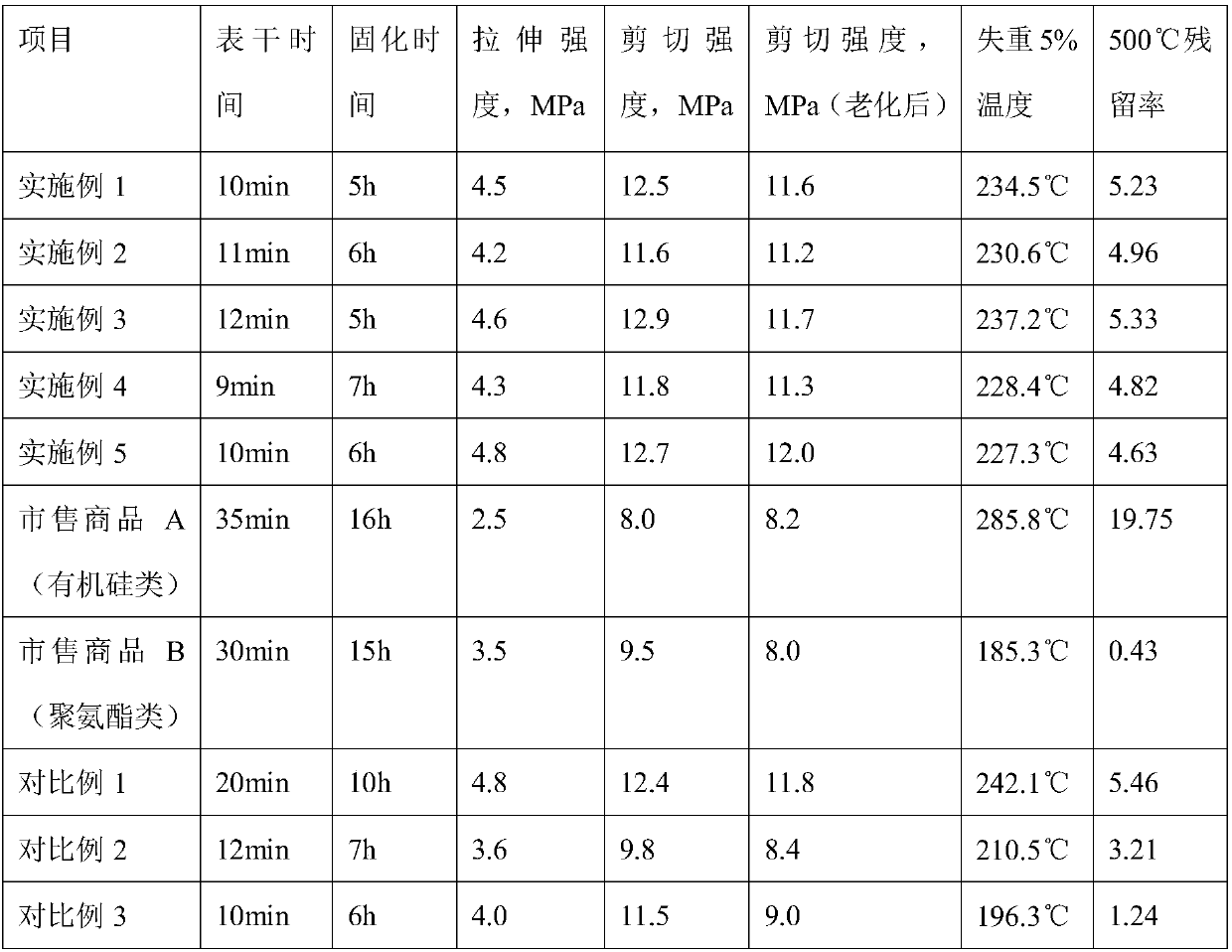

Embodiment 1

[0038] This embodiment 1 provides a method for preparing a high-temperature-resistant two-component polyurethane adhesive for an air filter. The prepared two-component polyurethane adhesive has the characteristics of fast curing speed, high bonding strength, and excellent high-temperature resistance. For bonding and sealing of air filters. The preparation method specifically includes:

[0039] Prepare component A:

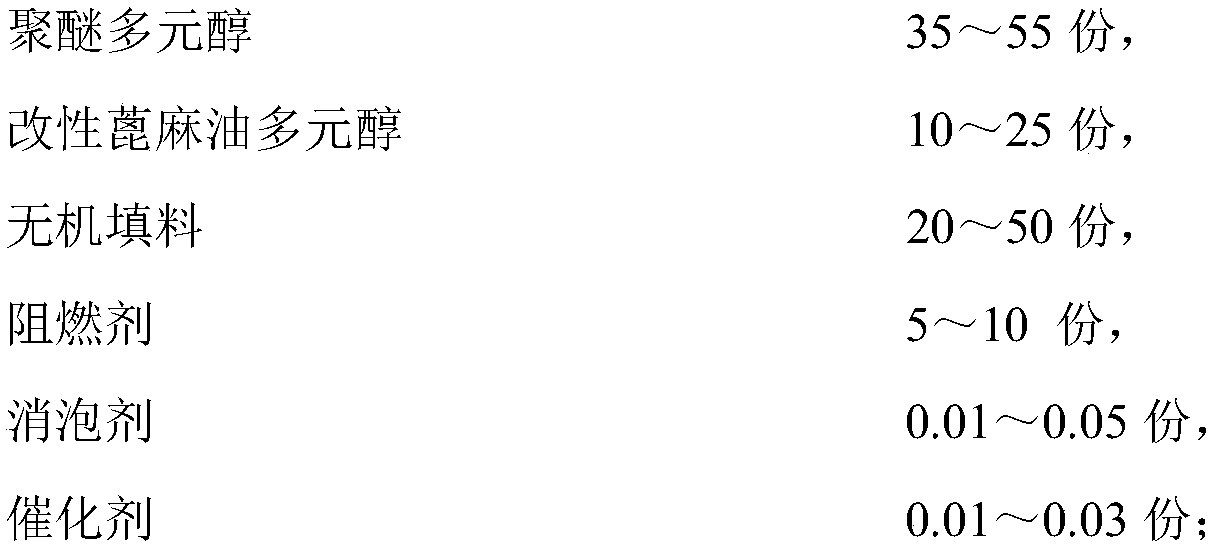

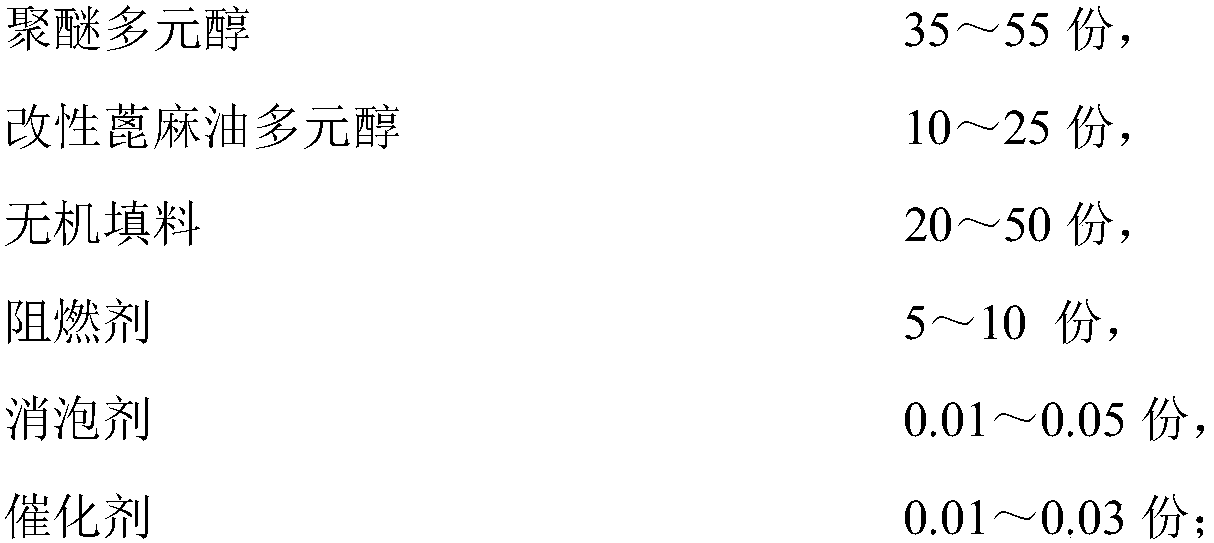

[0040] Get raw materials according to the following ratio:

[0041] The molecular weight of 15 mass parts is the polyoxypropylene trihydric alcohol of 500, the molecular weight of 20 mass parts is the polyoxypropylene glycol of 2000, the epoxy-modified castor oil of 16 mass parts, heat up to 110-120 ℃, while Vacuumize and dehydrate for 2-3 hours while stirring, and control the moisture index below 200ppm; cool down to 40-50°C, add 33 parts by mass of heavy calcium carbonate and 16 parts by mass of mica powder, fully knead evenly in a high-speed disperser, and the...

Embodiment 2

[0048] The second embodiment provides a method for preparing a high-temperature-resistant two-component polyurethane adhesive for an air filter. The prepared two-component polyurethane adhesive has the characteristics of fast curing speed, high bonding strength, and excellent high-temperature resistance. For bonding and sealing of air filters. The preparation method specifically includes:

[0049] Prepare component A:

[0050] Get raw materials according to the following ratio:

[0051] The molecular weight of 20 mass parts is the polyoxypropylene trihydric alcohol of 400, the molecular weight of 30 mass parts is the polyoxypropylene glycol of 1000, the epoxy-modified castor oil of 19 mass parts, heat up to 110-120 ℃, while Vacuumize and dehydrate for 2-3 hours while stirring, and control the moisture index below 200ppm; cool down to 40-50°C, add 30 parts by mass of light calcium carbonate and 10 parts by mass of aluminum oxide, and fully knead in a high-speed disperser. Then...

Embodiment 3

[0057] Embodiment 3 provides a method for preparing a high-temperature-resistant two-component polyurethane adhesive for air filters. The prepared two-component polyurethane adhesive has the characteristics of fast curing speed, high bonding strength, and excellent high-temperature resistance. For bonding and sealing of air filters. The preparation method specifically includes:

[0058] Prepare component A:

[0059] Get raw materials according to the following ratio:

[0060] 20 parts by mass of polyoxypropylene triol with a molecular weight of 600, 25 parts by mass of polyoxypropylene diol with a molecular weight of 1500, and 23 parts by mass of maleic anhydride-modified castor oil are heated up to 110-120°C while stirring While vacuuming and dehydrating for 2-3 hours, the moisture index is controlled below 200ppm; the temperature is lowered to 40-50°C, and 35 parts by mass of nano calcium carbonate and 15 parts by mass of titanium dioxide are fully kneaded in a high-speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com