Preparation method of carbon-nanotube-enhanced copper-based composite material

A technology of copper-based composite materials and carbon nanotubes, applied in electrolytic coatings, coatings, etc., to achieve the effect of ensuring integrity and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of preparation method of carbon nanotube reinforced copper-based composite material, concrete steps are:

[0025] (1) Put the multi-walled carbon nanotubes (the purity of the multi-walled carbon nanotubes is not less than 95%) in the acid solution for ultrasonic dispersion treatment for 30 minutes, heat to a temperature of 65°C and treat at a constant temperature for 10 hours, after filtering, washing and drying Obtain pretreated carbon nanotubes, wherein the acid solution is a mixed acid solution of concentrated sulfuric acid and concentrated nitric acid, and the volume ratio of the concentrated sulfuric acid and concentrated nitric acid in the acid solution is 3:1;

[0026] (2) Add the pretreated carbon nanotubes obtained in step (1) to the copper salt solution to prepare a carbon nanotube / copper salt composite solution, wherein the concentration of carbon nanotubes in the carbon nanotube / copper salt composite solution is 2g / L , the copper salt is...

Embodiment 2

[0031] Example 2: The preparation method of the carbon nanotube-reinforced copper-based composite material in this example is basically the same as in Example 1, except that the concentration of the carbon nanotubes in the carbon nanotube / copper salt composite solution in step (2) is 1g / L;

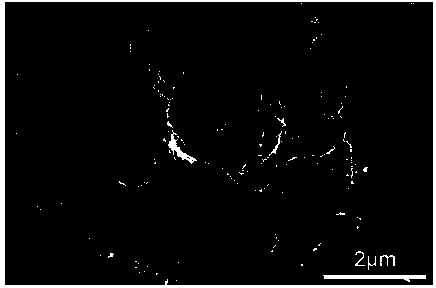

[0032] The microscopic morphology of the carbon nanotube-reinforced copper-based composite film of this embodiment is as follows: figure 2 shown, from figure 2 It can be seen that the carbon nanotubes are evenly distributed and embedded on the copper matrix, and the bonding between the carbon nanotubes and the copper matrix is good, and some longer carbon nanotubes connect multiple copper grains in series, which helps the stress in the composite material matrix after sintering. effective delivery of

[0033] The cross-sectional microscopic morphology of the carbon nanotube-reinforced copper-based composite material of this embodiment is as follows Figure 4 shown, from Figure 4 It...

Embodiment 3

[0035] Example 3: The preparation method of the carbon nanotube-reinforced copper-based composite material in this example is basically the same as that in Example 1, except that the cathode current density during electrodeposition in step (3) is 2A / dm 2 ;

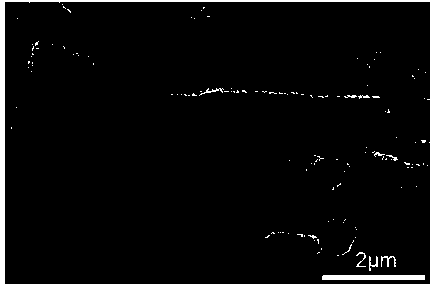

[0036] The microscopic morphology of the carbon nanotube-reinforced copper-based composite film of this embodiment is as follows: image 3 shown, from image 3 It can be seen that the carbon nanotubes are evenly distributed and embedded on the copper substrate, and the carbon nanotubes and the copper substrate are well bonded. Compared with Example 1, the average grain size of copper decreases due to the increase of the current density;

[0037] The relative density of the carbon nanotube-reinforced copper-based composite material prepared in this example is 97.3%, and the tensile strength is 267MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com