Fiber-like-structured lithium ion battery and preparation method

A lithium-ion battery, fibrous technology, applied in the fields of electrochemistry and automobile lightweight, can solve the problems of commercialization difficulties, and achieve the effect of less steps, simple operation and fast charging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

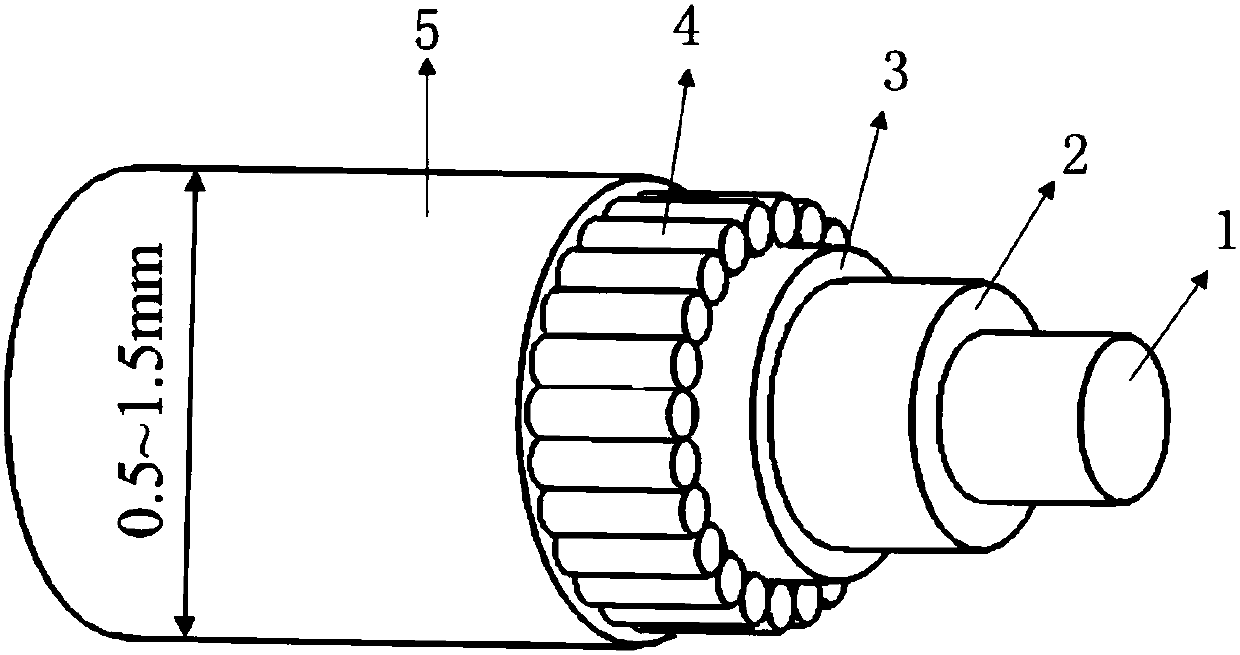

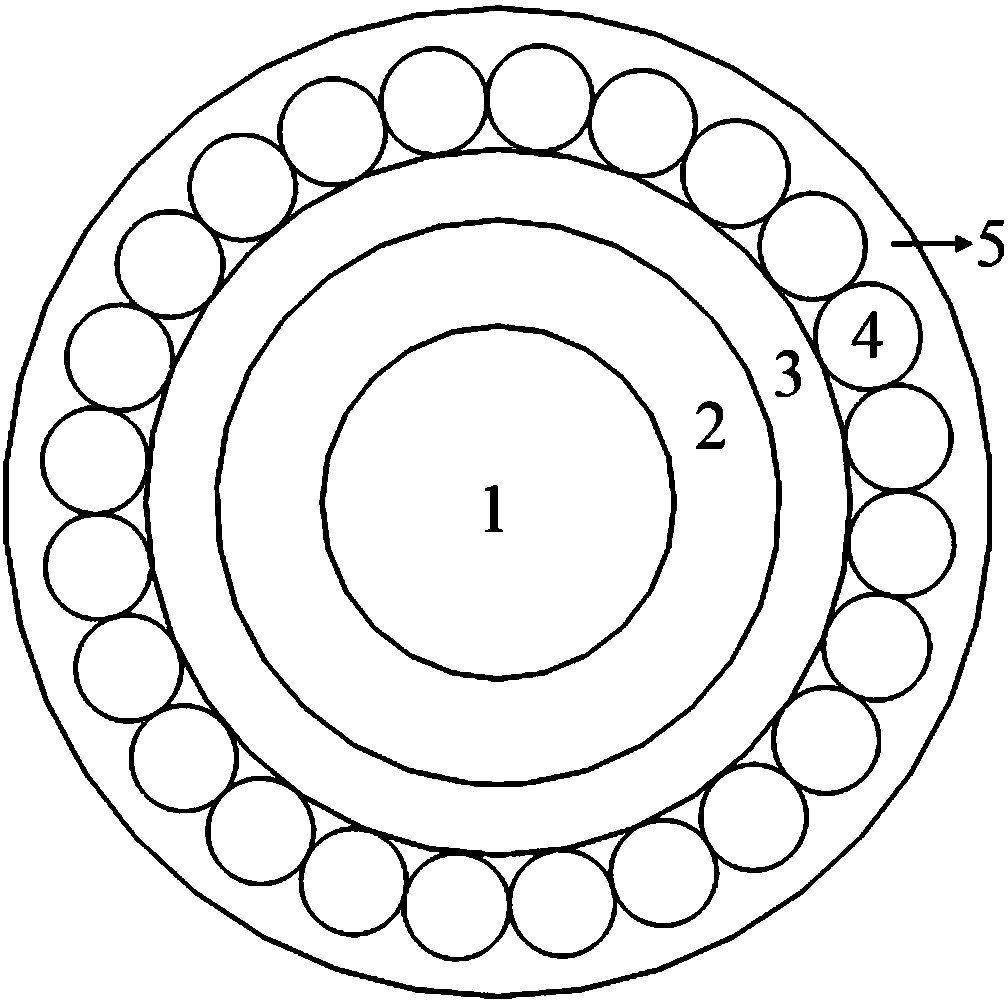

[0030] Such as Figure 1-3 As shown, the lithium-ion battery with a fibrous structure of the present invention includes a positive electrode current collector copper wire 1 , a positive electrode active material mixture 2 , a separator PP film 3 , a negative electrode carbon fiber 4 and a solid electrolyte 5 . The positive electrode current collector copper wire 1 is wrapped with a layer of positive electrode active material mixture 2, the outside of the positive electrode active material mixture 2 is wrapped with a layer of PP separator 3, the outside of the PP separator 3 is wrapped with a circle of negative electrode fibers 4, and the solid electrolyte 5 combines all the components, That is, the positive current collector copper wire 1, the positive active material mixture 2, the PP separator 3, and the negative fiber 4 are wrapped, and play the role of bonding all components.

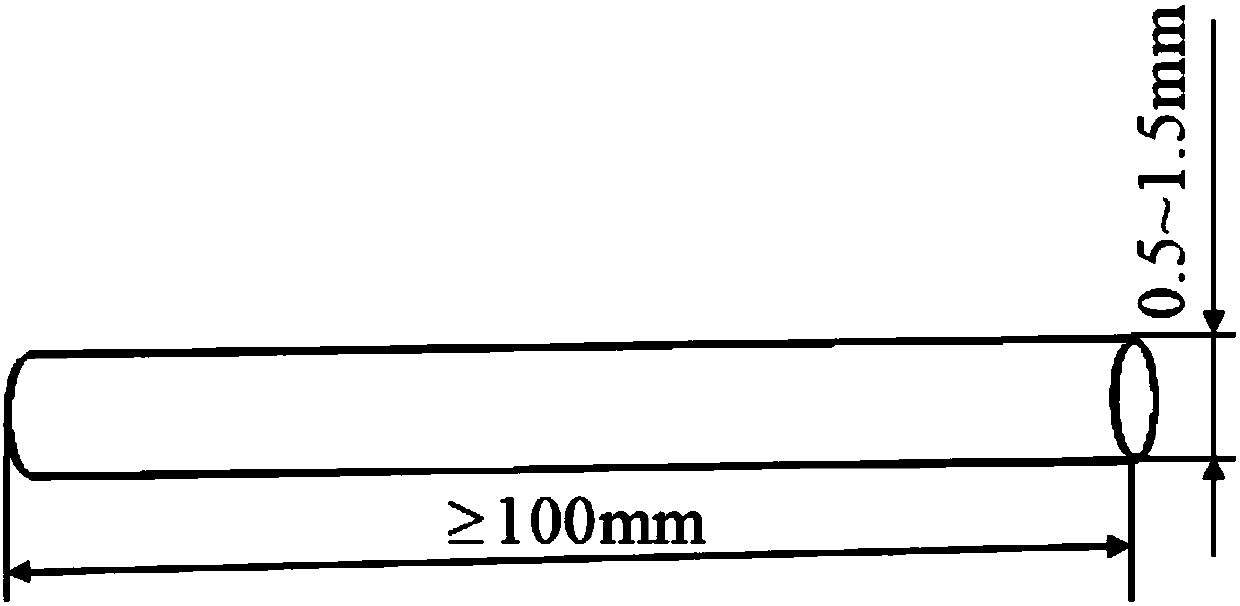

[0031] The shape of the lithium-ion battery having a fibrous structure is a long fiber, with an ...

Embodiment 2

[0039] Such as Figure 1-3 As shown, the lithium-ion battery with a fibrous structure of the present invention includes a positive electrode current collector nickel wire 1 , a positive electrode active material mixture 2 , a separator PP / PE / PP composite film 3 , negative electrode carbon fiber 4 and a solid electrolyte 5 . The positive electrode current collector nickel wire 1 is wrapped with a layer of positive electrode active material mixture 2, the outside of the positive electrode active material mixture 2 is wrapped with a layer of PP / PE / PP composite separator 3, and the outside of PP / PE / PP composite separator 3 is wrapped with a circle of negative electrode The fiber 4 and the solid electrolyte 5 wrap all the components, that is, the positive electrode current collector nickel wire 1, the positive electrode active material mixture 2, the PP / PE / PP composite separator 3, and the negative electrode fiber 4, and play the role of bonding all the components.

[0040] The sha...

Embodiment 3

[0048] Such as Figure 1-3 As shown, the lithium-ion battery with a fibrous structure of the present invention includes a positive electrode current collector copper wire 1 , a positive electrode active material mixture 2 , a separator PP film 3 , a negative electrode carbon fiber 4 and a solid electrolyte 5 . The positive electrode current collector copper wire 1 is wrapped with a layer of positive electrode active material mixture 2, the outside of the positive electrode active material mixture 2 is wrapped with a layer of PP separator 3, the outside of the PP separator 3 is wrapped with a circle of negative electrode fibers 4, and the solid electrolyte 5 combines all the components, That is, the positive current collector copper wire 1, the positive active material mixture 2, the PP separator 3, and the negative fiber 4 are wrapped, and play the role of bonding all components.

[0049] The shape of the lithium-ion battery having a fibrous structure is a long fiber, with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com