Preparation method of hydrophobic anti-fog surfaces

An anti-fog and hydrophobic technology, which is used in the process of producing decorative surface effects, manufacturing microstructure devices, decorative arts, etc., can solve the problems of being easily damaged by external forces, complicated preparation processes, etc., to reduce production costs, size and structure. Simple and beneficial to industrialized large-area production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

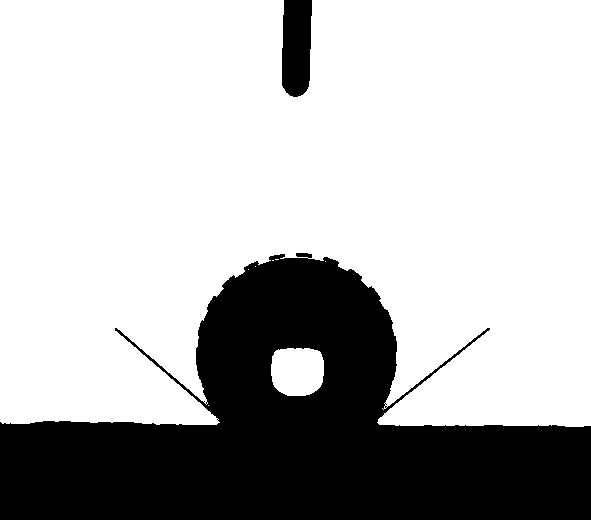

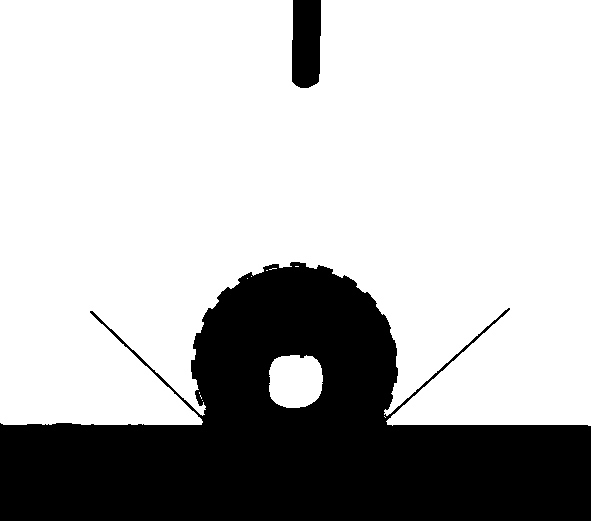

[0039] Such as figure 1 And shown, preparation method of the present invention comprises the following steps:

[0040] 1. Cleaning of the glass substrate: First, in order to improve the adhesion of the photoresist to the glass substrate and obtain a smoother film; ultrasonically wash the glass substrate for 10 minutes to remove organic matter on the surface of the glass substrate; secondly, put the glass substrate in absolute ethanol Ultrasonic shock cleaning for 10 minutes to remove residual acetone on the surface of the glass substrate; then shock-wash the glass substrate in deionized water for 10 minutes to remove inorganic substances on the surface of the glass substrate; To increase the adhesion between photoresist and glass substrate surface;

[0041] 2. Coating SU-8 2005 photoresist: Coat SU-8 2005 photoresist on the glass substrate treated in step 1; put it in a hot baking plate and bake it, and then cool the glass substrate naturally to room temperature;

[0042] 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com