Starch syrup specially used for concrete, and preparation method of starch syrup

A technology of starch syrup and concrete, which is applied in fermentation and other directions to achieve moderate viscosity, which is conducive to large-scale production, and has a significant effect of water reduction and retardation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

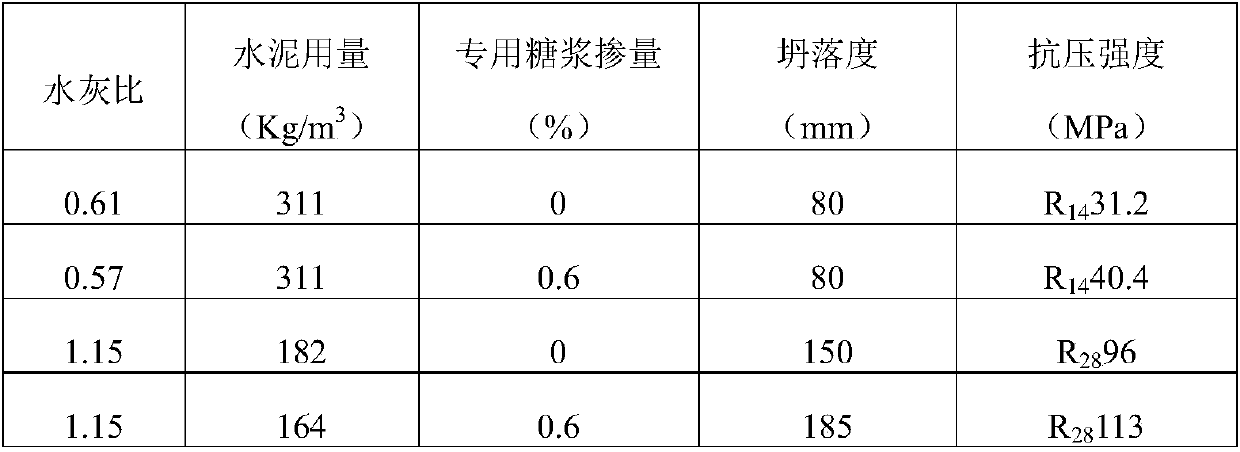

Image

Examples

Embodiment 1

[0045] A special starch syrup for concrete, the preparation method comprising the steps of:

[0046] (1) Slurry: adjust the starch into starch milk with a concentration of 20%, stir well, and after mixing thoroughly, add soda ash (sodium carbonate) to adjust pH=5.4, take 8U / g·Ds (U / g·Ds as each g The amount of α-amylase added to the dry material starch is added to the high-temperature-resistant α-amylase, and stirred evenly to obtain a starch slurry;

[0047] (2) Liquefaction: Spray and liquefy the starch slurry prepared in step (1), control the temperature at 105°C for 6 minutes, cool in vacuum, cool down to 90°C, maintain for 30 minutes, control the DE value to 12%, and inactivate the enzyme to obtain powder serous liquid;

[0048] (3) Saccharification: Cool down the liquefied slurry prepared in step (2) to 58°C, add β-amylase 100ml / ton dry base starch, pullulanase 50ml / ton dry base starch, and keep warm for saccharification after 24 hours Inactivate the enzyme to obtain the...

Embodiment 2

[0053] A special starch syrup for concrete, the preparation method comprises the following steps:

[0054] (1) Slurry adjustment: adjust the starch into starch milk with a concentration of 28%, fully stir, and after mixing thoroughly, add soda ash (sodium carbonate) to adjust the pH=5.8, and use 11U / g·Ds (U / g·Ds as each g The amount of α-amylase added to the dry material starch is added to the high-temperature-resistant α-amylase, and stirred evenly to obtain a starch slurry;

[0055] (2) Liquefaction: Spray and liquefy the starch slurry prepared in step (1), control the temperature at 108°C for 7 minutes, cool in vacuum, lower the temperature to 95°C, maintain it for 60 minutes, control the DE value to 15%, and inactivate the enzyme to obtain powder serous liquid;

[0056] (3) Saccharification: Cool down the slurry liquefaction solution prepared in step (2) to 60°C, add 200ml / ton dry-based starch of β-amylase and 150ml / ton dry-based starch of pullulanase, and keep saccharifi...

Embodiment 3

[0061] A special starch syrup for concrete, the preparation method comprises the following steps:

[0062] (1) Slurry: adjust the starch into starch milk with a concentration of 35%, stir well, and after mixing thoroughly, add soda ash (sodium carbonate) to adjust pH=6.2, with 14U / g·Ds (U / g·Ds as each g The amount of α-amylase added to the dry material starch is added to the high-temperature-resistant α-amylase, and stirred evenly to obtain a starch slurry;

[0063] (2) Liquefaction: Spray and liquefy the starch slurry prepared in step (1), control the temperature at 110°C for 9 minutes, cool in a vacuum, lower the temperature to 97°C, maintain for 90 minutes, control the DE value to 17%, and inactivate the enzyme to obtain powder serous liquid;

[0064] (3) Saccharification: Cool down the slurry liquefaction solution prepared in step (2) to 62°C, add β-amylase 300ml / ton dry base starch, pullulanase 200ml / ton dry base starch, keep warm and saccharify for 48 hours Inactivate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com