Light-transmitting resin type light guide cement material containing superhydrophobic titanium dioxide thin film, and preparation method of light-transmitting resin type light guide cement material

A light-transmitting resin and titanium dioxide technology, applied in the field of building materials, can solve the problems of affecting the light-transmitting performance of resin light-guiding cement-based materials, affecting the appearance of buildings, and difficult to clean, so as to achieve good self-cleaning performance, improve mechanical strength, and ensure The effect of light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

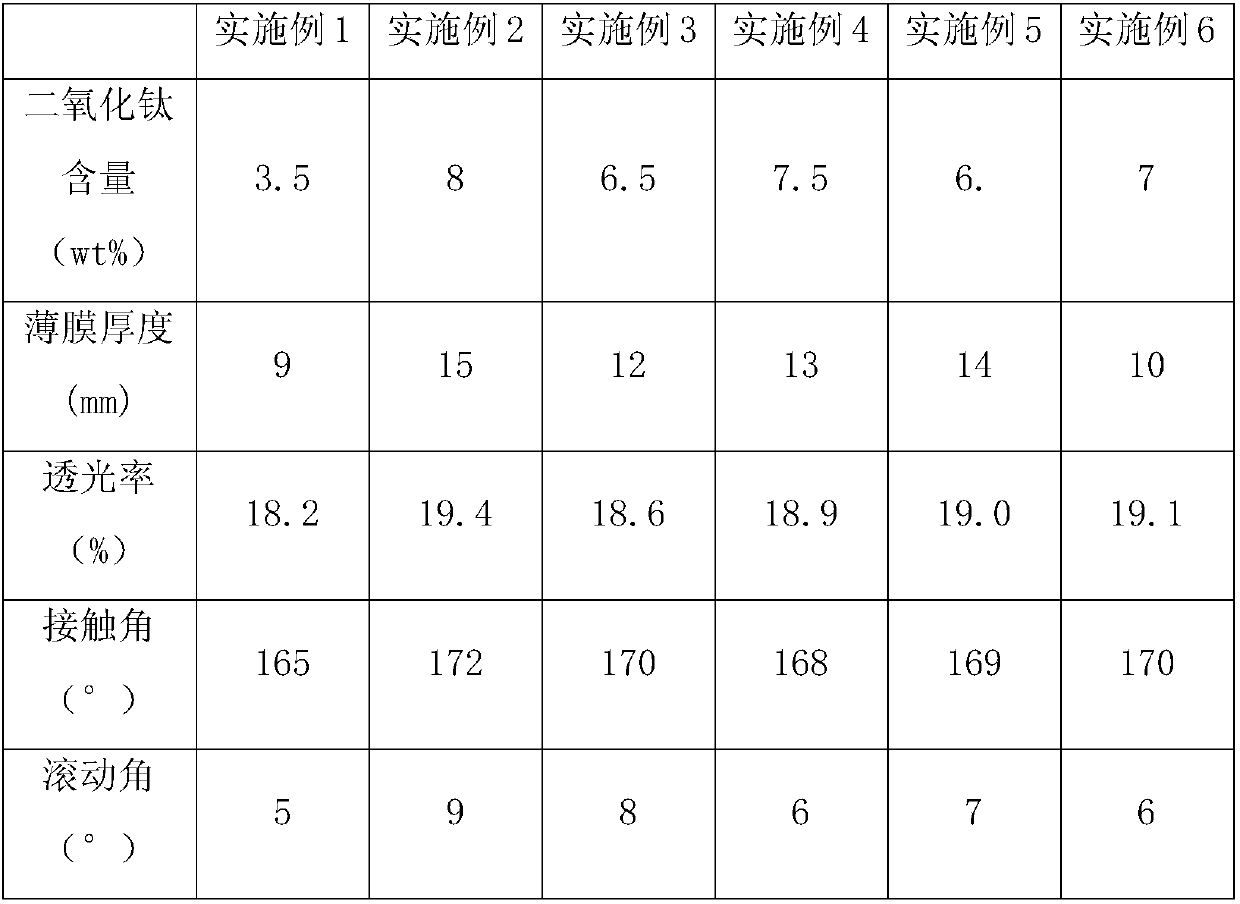

Examples

Embodiment 1

[0027] (1) Mix unsaturated polyester light-transmitting resin, initiator, and accelerator in a weight ratio of 1:0.01:0.003, stir, pour it into a mold, remove the mold after it hardens, and obtain a light transmittance of 90 % of light-transmitting resin units.

[0028] (2) Evenly coat the surface of the light-transmitting resin unit with silane coupling agent, transfer it to the mold of the light-transmitting cement board, add 0.75 parts of P·0 42.5MPa cement, 0.25 parts of mineral admixture II grade fly ash, high Performance Self-compacting cement mortar prepared by 0.006 parts of polycarboxylate superplasticizer, 0.001 parts of chopped polypropylene fiber with a length of 3 mm, 1.2 parts of fine sand with a particle size ≤ 1.18 mm, and 0.3 parts of water, until it reaches 50% strength After that, the formwork was removed, the formwork was removed, polished and polished to obtain an interface-enhanced light-transmitting resin-type light-guiding cement base material with a st...

Embodiment 2

[0032] (1) Mix unsaturated polyester light-transmitting resin, initiator, and accelerator in a weight ratio of 1:0.03:0.005, stir, pour it into a mold, remove the mold after it hardens, and obtain a light transmittance of 90 -98% light-transmitting resin unit.

[0033] (2) Evenly coat the surface of the light-transmitting resin unit with silane coupling agent, transfer it to the mold of the light-transmitting cement board, add 0.75 parts of P·0 42.5MPa cement, 0.25 parts of mineral admixture II grade fly ash, high Performance Self-compacting cement mortar prepared by 0.006 parts of polycarboxylate superplasticizer, 0.001 parts of chopped polypropylene fiber with a length of 3 mm, 1.2 parts of fine sand with a particle size ≤ 1.18 mm, and 0.3 parts of water, until it reaches 50% strength After that, the formwork was removed, the formwork was removed, polished and polished to obtain an interface-enhanced light-transmitting resin-type light-guiding cement base material with a str...

Embodiment 3

[0037] (1) Mix unsaturated polyester light-transmitting resin, initiator, and accelerator in a weight ratio of 1:0.02:0.004, stir, pour it into a mold, remove the mold after it hardens, and obtain a light transmittance of 95 % of light-transmitting resin units.

[0038] (2) Evenly coat the surface of the light-transmitting resin unit with aluminate coupling agent, transfer it to the mold of the light-transmitting cement board, add 0.75 parts of P·0 42.5MPa cement, and 0.25 parts of mineral admixture II grade fly ash , 0.006 parts of high-performance polycarboxylate superplasticizer, 0.001 part of chopped polypropylene fiber with a length of 3 mm, 1.2 parts of fine sand with a particle size of ≤ 1.18 mm, and 0.3 parts of water to prepare self-compacting cement mortar until it reaches 50% After the strength is reached, the formwork is removed, the formwork is removed, polished and polished to obtain an interface-enhanced light-transmitting resin-type light-guiding cement base ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com