Magnesium-calcium ramming material produced from waste refractory materials and its manufacturing method

A technology for discarding refractory materials and ramming materials, applied in the field of environmental protection materials, can solve the problems of substandard discharge, environmental pollution of iron and steel, shortage of high-quality refractory raw materials, etc., to reduce costs, improve thermal shock stability, and reduce hydration erosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Electric furnace bottom ramming material, furnace slope repair material

[0023] The used magnesia-iron bricks recovered by the cement plant are broken into 5mm particle size materials after removing the metamorphic layer, and the waste magnesia-iron brick aggregates are obtained;

[0024] The used magnesia-calcium bricks recovered from the steel mill are broken into 5mm particle size materials after removing the steel slag to remove the metamorphic layer, and the aggregate of the waste magnesia-calcium bricks is obtained;

[0025] Crush the synthetic magnesia-calcium-iron sand produced by the company into 0-8㎜ grain size material to obtain high-calcium and low-iron magnesia aggregate;

[0026] The used high-purity or mid-grade magnesia bricks recovered from the glass factory are finely ground into fine powder with a particle size of ≦0.074mm to obtain waste magnesia brick fine powder,

[0027] The fine powder of the iron oxide powder particle size of 0.0...

Embodiment 2

[0035] Embodiment 2: GOR furnace bottom joint material, converter live furnace bottom joint material, AOD furnace bottom masonry material

[0036] The raw materials used and the preparation method are the same as in Example 1, and the proportioning ratio is as follows.

[0037]

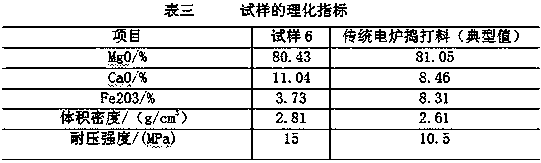

[0038]

[0039] According to the requirements and technical conditions of GOR furnace bottom joint material, converter live furnace bottom joint material, and AOD furnace bottom masonry material, sample 1 has the highest bulk density and compressive strength when heated to 450°C, while the traditional material sample is the lowest , by percentage, the formula data used is: waste magnesia-iron brick aggregate 5%, waste magnesia-calcium brick aggregate 78%, high-calcium and low-iron magnesia aggregate 5%, waste mid-grade magnesia brick fine powder 5%, waste iron Powder 0.5%, sodium sulfate 0.5%, sodium carbonate 0.5%, and organic binder 7% are mixed evenly to make environmentally friendly magnesiu...

Embodiment 3

[0040]Example 3: Environment-friendly magnesia-calcium plastic (ramming) material for AOD furnace, GOR furnace, back seam of ordinary converter, and furnace mouth

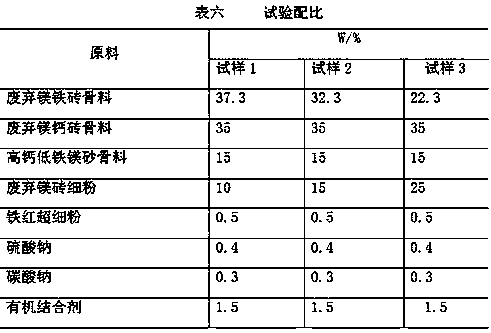

[0041] The raw materials used and the preparation method are the same as in Example 1, and the proportioning ratio is as follows.

[0042]

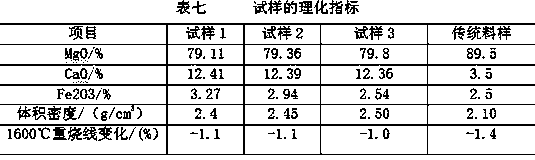

[0043]

[0044] According to the requirements and technical conditions of AOD furnace, GOR furnace, converter back seam and furnace mouth, the required volume density / (g / cm 3 ) ≥ 2.4, 1600°C change in reburning line / (%) ≤ -1.3, sample 3 has the highest bulk density, and the lowest change in reburning line, by percentage, the formula data used is: waste high-purity magnesia brick fine powder is 25%, Waste magnesia iron brick aggregate 22.3%, waste magnesia calcium brick aggregate 35%, high calcium and low iron magnesia aggregate 15%, waste iron powder 0.5%, sodium sulfate 0.4%, sodium carbonate 0.3%, organic binder 1.5% After mixing evenly, it is made into an environment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com