Preparation of neohesperidin dihydrochalcone

A technology for the enzymatic hydrolysis of hesperidin dihydrochalcone and hesperidin dihydrochalcone, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., which can solve the problem of high cost and achieve step-by-step Simple, low production cost, simple refining steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preferred embodiment of the present invention provides a kind of preparation method of new methyl hesperidin dihydrochalcone, comprising the following steps:

[0036] Hesperidin is hydrogenated to synthesize hesperidin dihydrochalcone.

[0037] Hesperetin dihydrochalcone is enzymatically hydrolyzed to produce hesperetin dihydrochalcone.

[0038] React hesperetin dihydrochalcone with neohesperidose or its analogues to obtain neomethylhesperidin dihydrochalcone.

[0039] The synthetic route is as follows:

[0040]

[0041] Hesperidin is hydrogenated to synthesize hesperidin dihydrochalcone, which can be reduced under the condition of stannous chloride, oxalic acid, potassium borohydride, sodium borohydride as reducing agent, or under the condition of protective gas and catalyst Next, direct hydrogen reduction. Hesperetin dihydrochalcone is converted into hesperetin dihydrochalcone by enzymatic hydrolysis reaction, which has obvious advantages compared with addin...

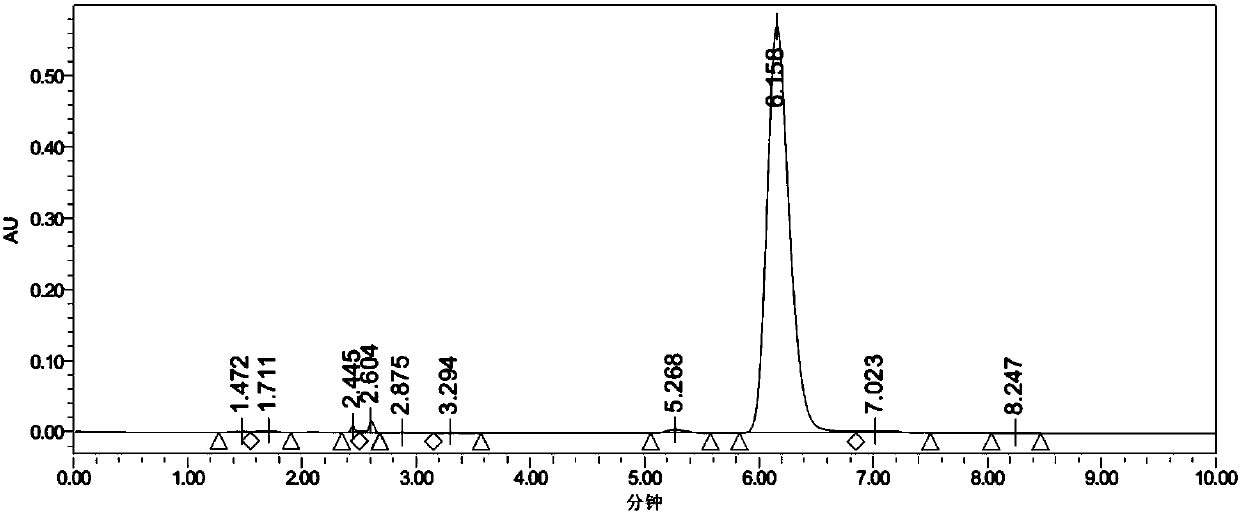

Embodiment 1

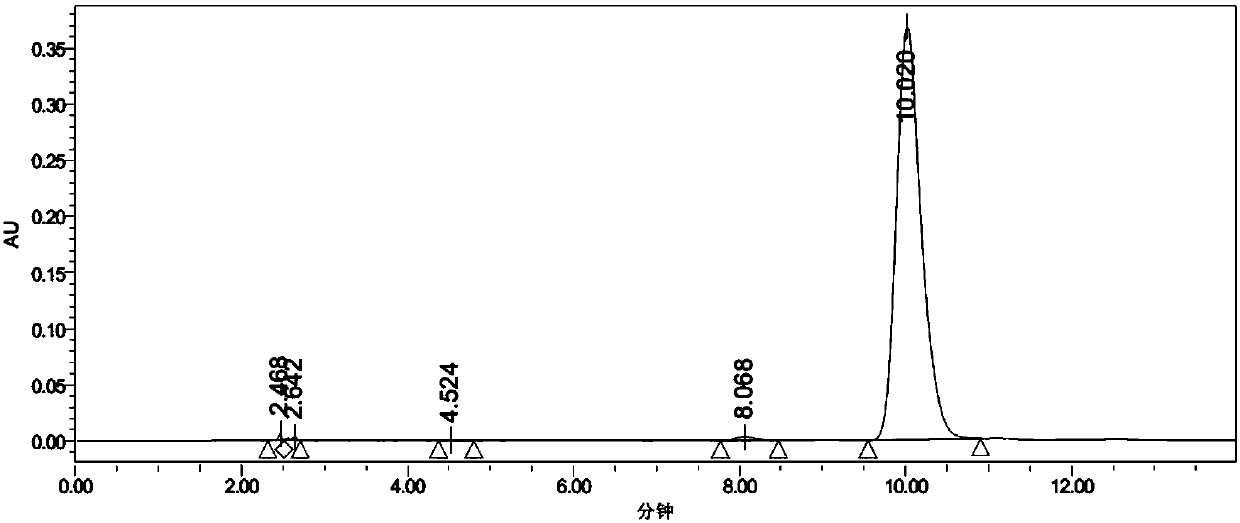

[0060] Hesperidin 98% 5kg, dissolve with 50L concentration of 10% sodium hydroxide solution, feed nitrogen as protective gas, catalyst Pd / C dosage is 500g, feed hydrogen under normal temperature and pressure, stir while adding, reaction time For 8 hours, the stirring speed is 800 / r·min-1. After the reaction, recover the catalyst, adjust the pH to 6, add 1 kg of activated carbon, stir for 1.5 hours, filter, and place the filtrate at 4°C for 12 hours to crystallize, recrystallize the coarse crystals with water, and dry to obtain hesperidin dihydrochar Ketone 4.9kg, content 98.5%, stir hesperidin dihydrochalcone with 50 times the amount of water evenly, add hesperidinase 50g, heat to 50 degrees, keep warm for 24h, filter and dry to obtain hesperetin dihydrochalcone Ketone 2.4kg, content 98.6%, stir hesperetin dihydrochalcone with 50 times the amount of water, add 2.5kg new hesperidose, 50g galactosyltransferase, react at 60 degrees for 24h, pass cooling water to stir and analyze ...

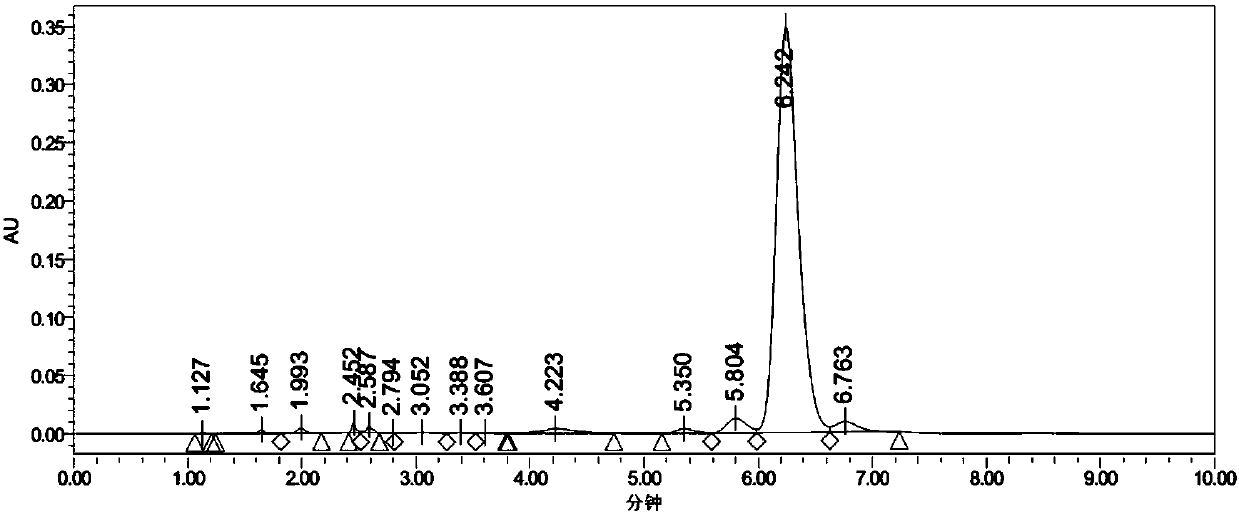

Embodiment 2

[0062] Hesperidin 98% 5kg is dissolved in 5% sodium hydroxide solution with 50L concentration, feeds nitrogen as protective gas, catalyst skeleton nickel consumption is 1000g, feeds hydrogen under normal temperature and pressure, stirs while adding, and the reaction time is For 12 hours, the stirring speed was 1000 / r·min-1. After the reaction is over, recover the catalyst, adjust the pH to 5.5, add 500g of activated carbon, stir for 2 hours, filter, put the filtrate at 8°C for 15 hours to crystallize, recrystallize the coarse crystals with water, and dry to obtain hesperidin dihydrochar Ketone 4.5kg, content 98.3%, stir hesperidin dihydrochalcone with 60 times the amount of water evenly, add hesperidinase 60g, heat to 55 degrees, keep warm for 24h, filter and dry to obtain hesperetin dihydrochalcone Ketone 2.2kg, content 98.4%, stir hesperetin dihydrochalcone with 60 times the amount of water, add 2.2kg new hesperidose, 60g glucotransferase, react at 65 degrees for 24 hours, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com