Less-sulfur and oxidization control brewing technology of amur grape sherry

A kind of mountain grape and process technology, applied in the field of brewing technology with low sulfur and oxidation control, can solve the problems of restricting the development of mountain grapes, dark red wine, unbalanced taste, etc., and achieve improved utilization value, low volatile acid and full taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

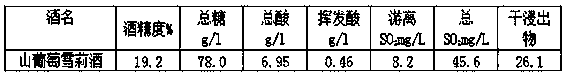

Image

Examples

Embodiment 1

[0029] A low-sulfur and oxidation-controlled brewing process of mountain grape sherry wine, comprising the steps of:

[0030] (1) Hand-picked 38 tons of mountain grapes and 4 tons of cabernet sauvignon grapes, selected and removed moldy and rotten fruits, raw green fruits, and secondary fruits, and destemmed and crushed them.

[0031] (2) Add 1.26 L of sulfurous acid aqueous solution with a sulfur dioxide content of 6% to the grape must obtained in step (1).

[0032] (3) The processed grape must is pumped to a 60-ton fermenter, and pectinase is added to the top of the tank at the same time as feeding, dosage: 840g. Add evenly in three times, then add 6.3kg of active dry yeast in an amount of 150mg / L, and ferment. During the fermentation, oxygen is circulated once a day to obtain a fermented liquid.

[0033] (4) The fermentation temperature of the fermentation broth is controlled at 22-24°C. When the specific gravity is 1050 after fermentation, samples are taken to test the al...

Embodiment 2

[0039] In the following examples, the pectinase was optivin purchased from France, and the active dry yeast was selected local wild yeast in Jiayuguan.

[0040] (1) Manually harvest 38 tons of mountain grapes and 4 tons of cabernet sauvignon grapes, select and remove the moldy and rotten fruits, raw green fruits and secondary fruits, destemming and crushing, the destemming rate is 95%, and the crushing rate is 85%.

[0041] (2) Add 1.26 L of sulfurous acid aqueous solution with a sulfur dioxide content of 6% to the grape must treated in step (1).

[0042] (3) Pump the grape must treated in step (2) into a horizontal rotary fermenter with a volume of 60 tons. While feeding, add pectinase evenly on the top of the tank three times, dosage: 840g. Then add 6.3kg of active dry yeast according to the amount of 150mg / L (add the active dry yeast to the grape juice before use, mix carefully, let it stand for rehydration, and stir gently at the same time to activate, then add) to ferment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com