A method of atomic deposition

A technology of atomic deposition and plasma, which is applied in metal material coating technology, coating, gaseous chemical plating, etc., can solve the problems of film quality degradation, reduction of film growth process control accuracy, ion beam current loss, etc., and achieve structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

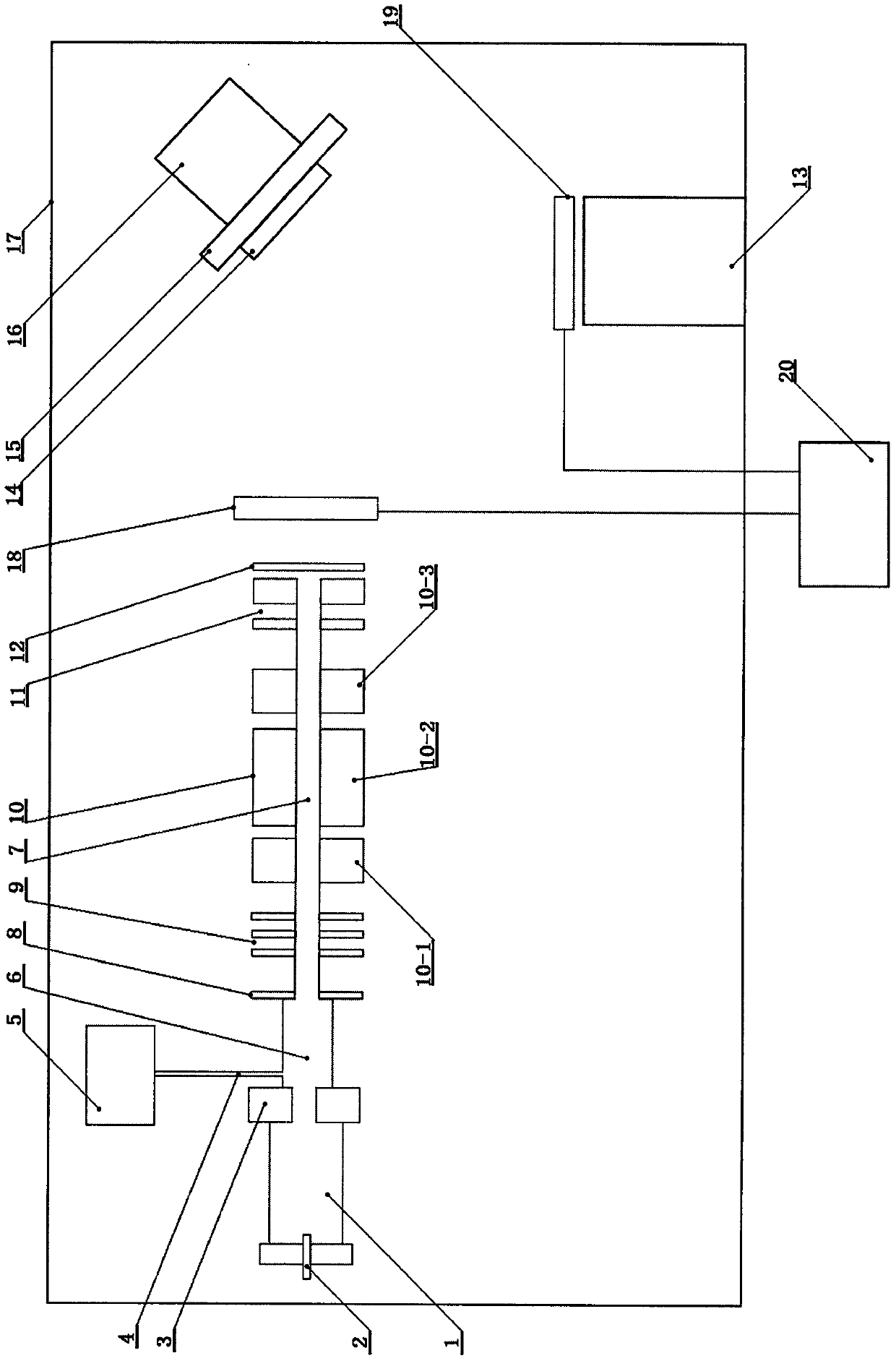

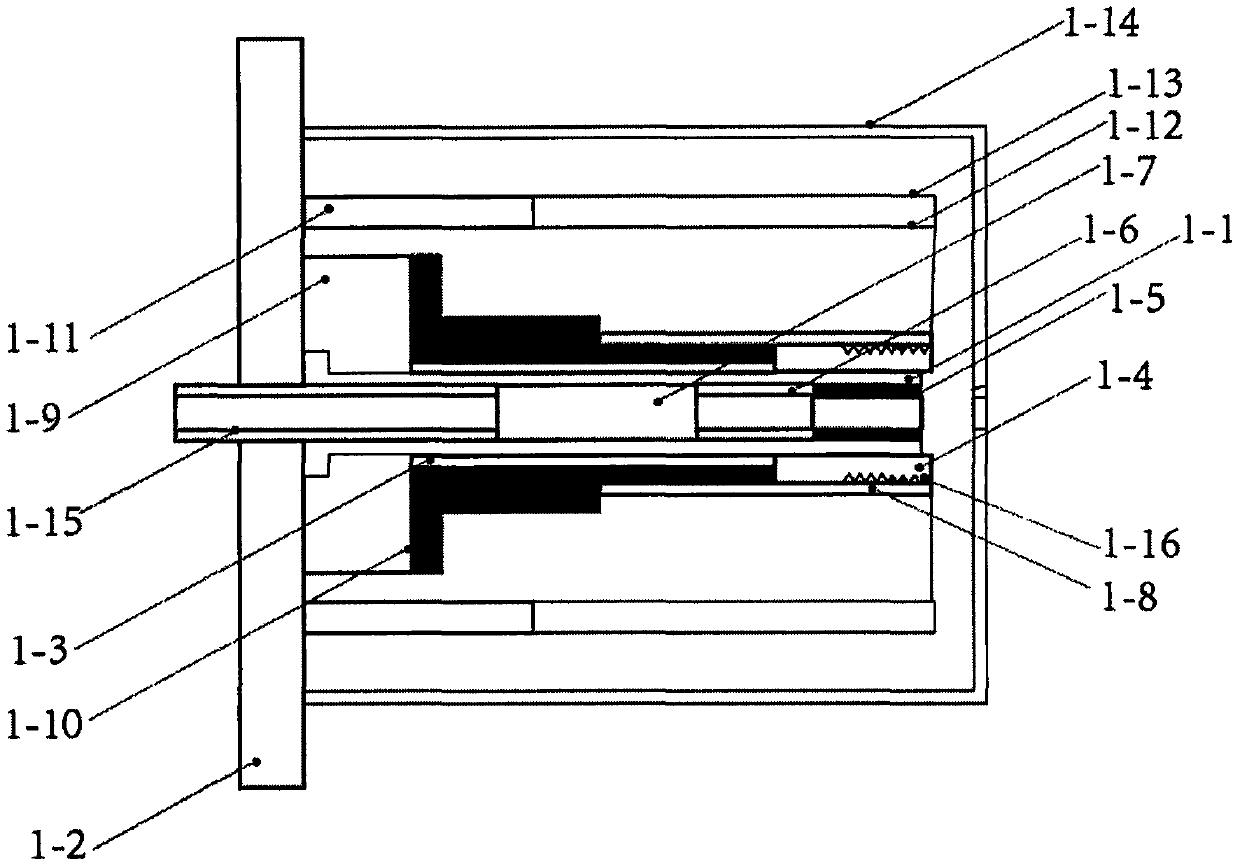

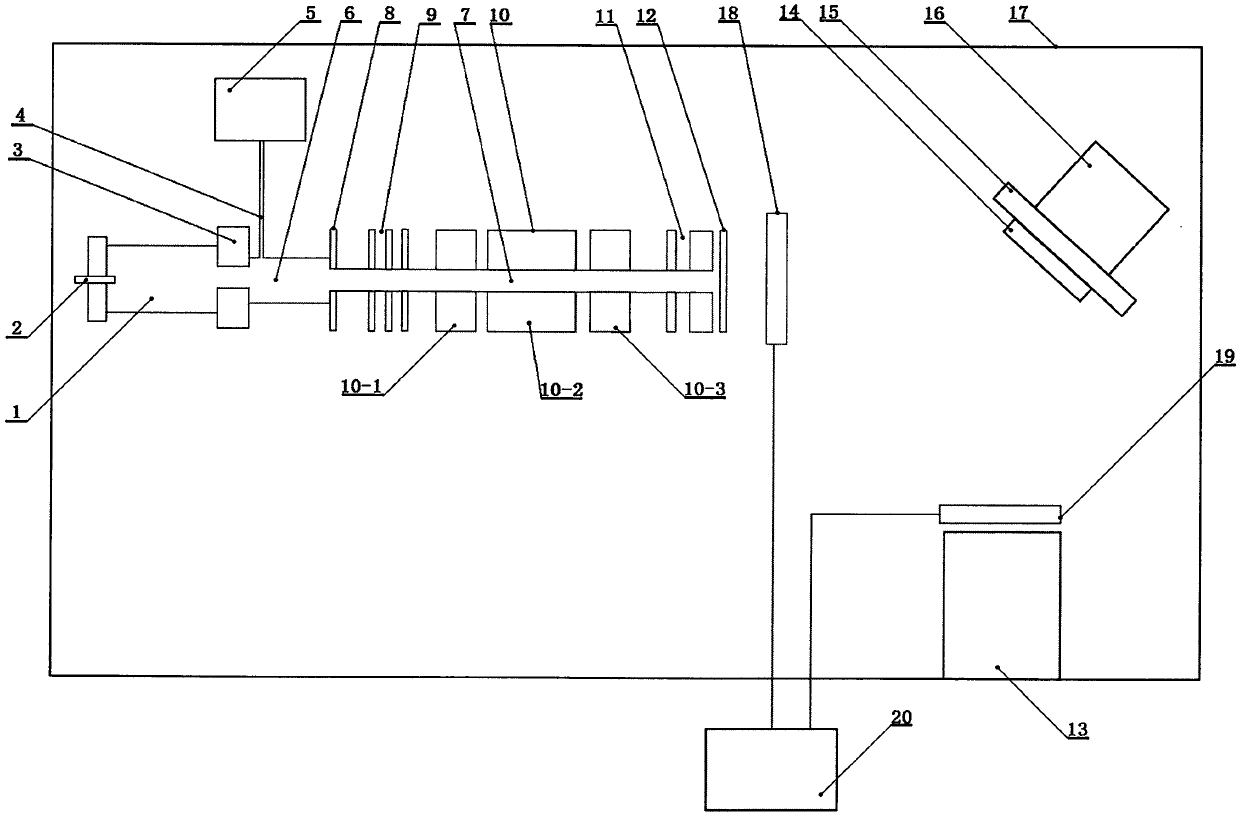

[0030] Such as figure 1 It is a schematic diagram of the structure of the present invention, such as figure 2 It is a schematic diagram of the enlarged structure of the hollow cathode. The device mainly includes an ion beam composed of a hollow cathode (1), a trigger module (2), an anode (3), a gas pipe (4), a gas storage tank (5), and a plasma chamber (6). Source, drift tube (7), extraction electrode (8), electrode group I (9), three independent quadrupole group I (10-1), quadrupole group II (10-2), quadrupole Quadrupole rod (10) composed of rod group III (10-3), electrode group II (11), stainless steel grid (12), electron beam evaporation source (13), sample (14), sample stage (15), Displacement stage (16), vacuum chamber (17), baffle plate I (18), baffle plate II (19), control unit (20) and cable, described hollow cathode (1) mainly comprises graphite cathode tube (1-1 ), stainless steel base (1-2), aluminum inner sleeve (1-3), ceramic heating tube (1-4), launch tube (1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com