Radio frequency elastic contact structure used for welding-free interconnection

An elastic contact and radio frequency technology, applied in the direction of connection, two-pole connection, two-part connection device, etc., can solve the problems that the adapter can no longer be installed, the structure cannot be disassembled, and the plugging force is large, so as to facilitate subsequent maintenance and replacement and meet Actual use requirements, the effect of increasing the creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be described below in conjunction with specific embodiments.

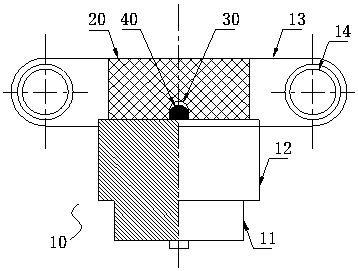

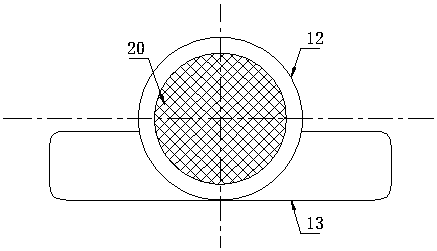

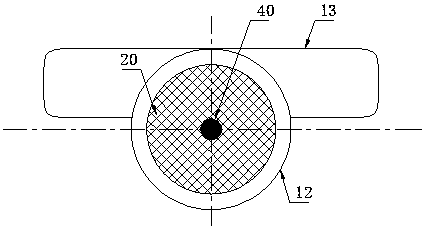

[0019] Such as figure 1 Shown is the front view of the RF elastic contact structure for solderless interconnection according to the present invention, figure 2 for figure 1 Top view of image 3 for figure 1 Bottom view. The radio frequency elastic contact structure of the present invention is used for mating and mating with the PCB board. The upper and lower edges of each plated through hole are also provided with counterbores, and the plated through holes are used to accommodate the radio frequency elastic contact of the present invention. For structure, the counterbore is used to fit and lock the radio frequency transmission structure of the present invention.

[0020] The radio frequency elastic contact structure of the present invention includes a casing 10 made of a copper-based alloy material. The casing 10 directly contacts the plated through holes on the PCB. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com