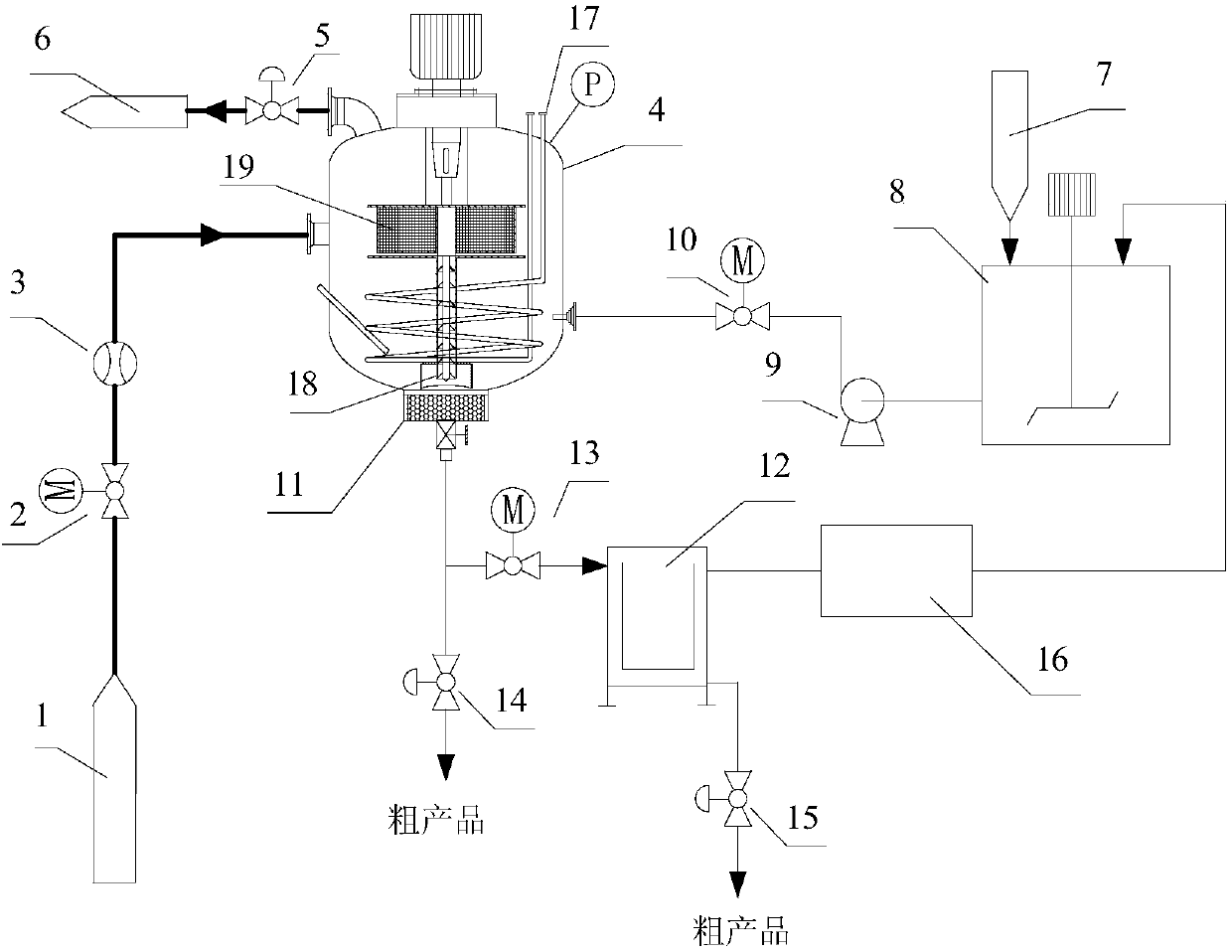

Inner-circulation supergravity heterogeneous-catalysis hydrogenation unit and application thereof

A hydrogenation device and heterogeneous catalysis technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of long process flow, uncontrollable hydrogenation reaction time, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Inner cycle high gravity heterogeneous catalysis for selective hydrogenation of cinnamaldehyde, the steps are as follows:

[0041] 1) 100mL cinnamic acid is added in the ethanol of 1L, then add the Pt-Ni alloy catalyst (the content of Pt in the described Pt-Ni alloy catalyst is 2wt% in the particle diameter of 2.0g is 50nm. Because Pt-Ni alloy catalyst is easy It is oxidized, so it needs to be reduced in hydrogen at 400°C for 2 hours before use), and after mixing uniformly in the premixing device, a suspension is obtained;

[0042] 2) Purge the internal circulation rotary packed bed with high-purity nitrogen at room temperature for 5 minutes, remove the air in the internal circulation rotary packed bed, and preheat at 130°C for 20 minutes, and pass the suspension obtained in step 1) into the internal circulation rotary packed bed After mixing for 1 hour, hydrogen gas was introduced, and the reaction was completed at a rotation speed of 2000 rpm, 3 MPa, and 90 ° C to obt...

Embodiment 2

[0049] The method for the hydrogenation of chloronitrobenzene with high gravity heterogeneous catalysis in internal circulation, the steps are as follows:

[0050] 1) Add 200ml of chloronitrobenzene to 2L of ethanol, then add 1.5g of Pt catalyst with a particle size of 20nm, and mix well in the premixing device to obtain a suspension;

[0051] 2) Purge the internal circulation rotary packed bed with high-purity nitrogen at room temperature for 5 minutes, remove the air in the internal circulation rotary packed bed, and preheat at 130°C for 20 minutes, and pass the suspension obtained in step 1) into the internal circulation rotary packed bed After 1 hour, hydrogen gas was introduced again, and the reaction was carried out at 1800 rpm, 2 MPa, and 120°C for 1 hour to obtain a liquid-solid mixture;

[0052] 3) After the liquid-solid mixture in step 2) is separated by the liquid-solid separation device at the bottom of the internal circulation rotating packed bed, the catalyst is ...

Embodiment 3

[0058] The method for the hydrogenation of cinnamaldehyde with high-gravity heterogeneous catalysis in internal circulation, the steps are as follows:

[0059] 1) Add 300mL of cinnamaldehyde to 3L of ethanol, then add 3.0g of Pt catalyst with a particle size of 20nm, mix evenly in a premixing device to obtain a suspension;

[0060] 2) Purge the internal circulation rotary packed bed with high-purity nitrogen at room temperature for 5 minutes, remove the air in the internal circulation rotary packed bed, and preheat at 110°C for 20 minutes, and pass the suspension obtained in step 1) into the internal circulation rotary packed bed for 1 hour After that, hydrogen gas was introduced again, and the reaction was carried out at 7 MPa and 110° C. for 1 hour at a rotational speed of 2000 rpm to obtain a liquid-solid mixture;

[0061] 3) After the liquid-solid mixture in step 2) is separated by the liquid-solid separation device at the bottom of the internal circulation rotating packed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com