Low-VOC (Volatile Organic Compound) glass fiber enhanced polypropylene composite material plate for automobile and preparation method thereof

A composite material board and polypropylene technology, applied in chemical instruments and methods, paper/cardboard layered products, glass/slag layered products, etc., can solve problems such as secondary release, achieve high production efficiency and reduce VOC content and emission, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

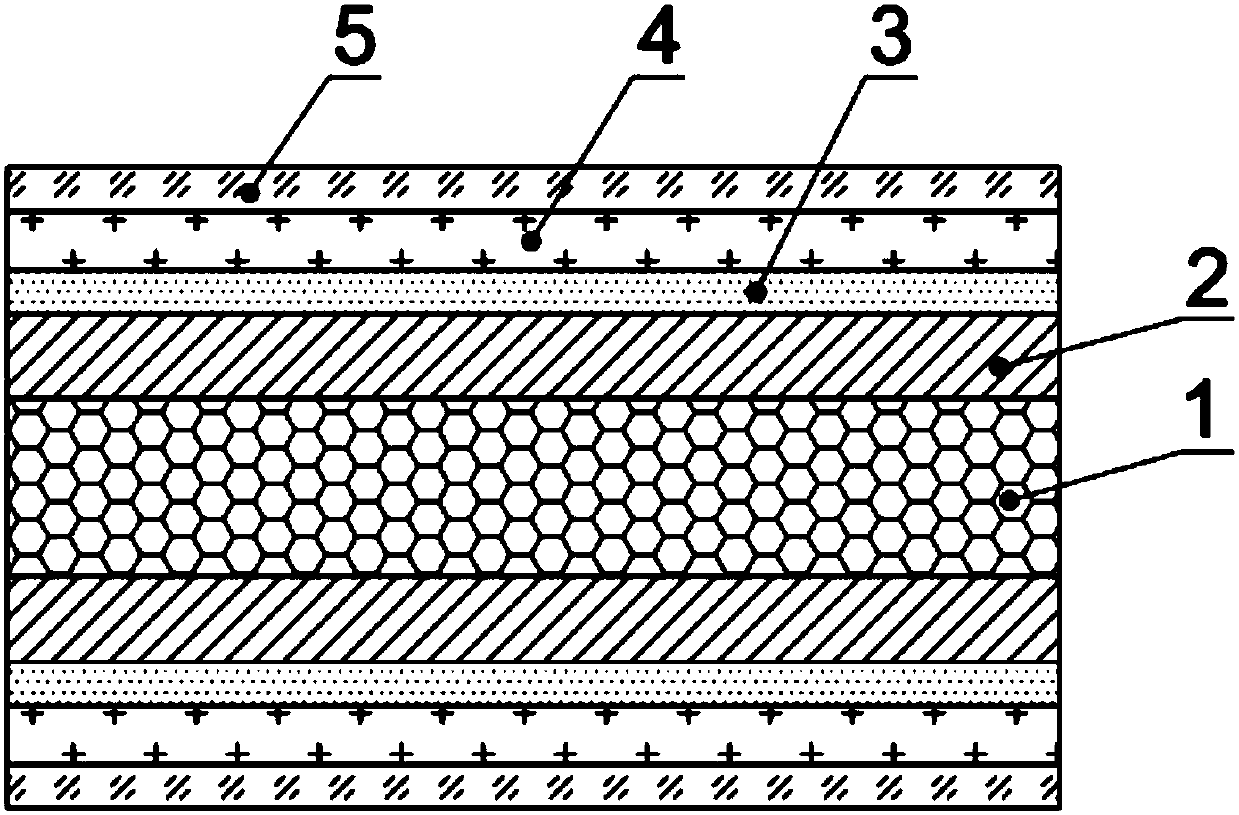

[0031] like figure 1 As shown, a low-VOC glass fiber reinforced polypropylene composite material board for vehicles includes a honeycomb paper core 1, the upper and lower surfaces of the honeycomb paper core 1 are provided with a glass fiber mat 2, and the surface of the glass fiber mat 2 is provided with a hot melt adhesive Layer 3, the surface of the hot melt adhesive layer 3 is provided with a polypropylene mixed coating 4, the surface of the polypropylene mixed coating 4 is coated with a self-cleaning layer 5, and the self-cleaning layer 5 is a nano-iron-based titanium dioxide composite photocatalyst coating, The thickness of the self-cleaning layer 5 is 0.9 mm. The glass fiber mat 2 is an alkali-free glass fiber chopped strand mat.

[0032] The preparation method of the above-mentioned low-VOC vehicle glass fiber reinforced polypropylene composite material board includes the following raw materials in parts by mass: 45 parts of water-soluble maleic anhydride modified pol...

Embodiment 2

[0039] like figure 1 As shown, a low-VOC glass fiber reinforced polypropylene composite material board for vehicles includes a honeycomb paper core 1, the upper and lower surfaces of the honeycomb paper core 1 are provided with a glass fiber mat 2, and the surface of the glass fiber mat 2 is provided with a hot melt adhesive Layer 3, the surface of the hot melt adhesive layer 3 is provided with a polypropylene mixed coating 4, the surface of the polypropylene mixed coating 4 is coated with a self-cleaning layer 5, and the self-cleaning layer 5 is a nano-iron-based titanium dioxide composite photocatalyst coating, The thickness of the self-cleaning layer 5 is 1.0 mm. The glass fiber mat 2 is an alkali-free glass fiber chopped strand mat. A waterproof layer is coated between the glass fiber mat 2 and the hot melt adhesive layer 3 .

[0040] The preparation method of the above-mentioned low-VOC vehicle glass fiber reinforced polypropylene composite material board includes the f...

Embodiment 3

[0047] like figure 1 As shown, a low-VOC glass fiber reinforced polypropylene composite material board for vehicles includes a honeycomb paper core 1, the upper and lower surfaces of the honeycomb paper core 1 are provided with a glass fiber mat 2, and the surface of the glass fiber mat 2 is provided with a hot melt adhesive Layer 3, the surface of the hot melt adhesive layer 3 is provided with a polypropylene mixed coating 4, the surface of the polypropylene mixed coating 4 is coated with a self-cleaning layer 5, and the self-cleaning layer 5 is a nano-iron-based titanium dioxide composite photocatalyst coating, The thickness of the self-cleaning layer 5 is 1.2 mm. The glass fiber mat 2 is an alkali-free glass fiber chopped strand mat.

[0048] The preparation method of the above-mentioned low-VOC glass fiber reinforced polypropylene composite material board for vehicles includes the following raw materials in parts by mass: 55 parts of water-soluble maleic anhydride modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com