Antimicrobial mildew-resistant automobile interior trim and preparation method thereof

A technology for automotive interior parts, antibacterial and antifungal, which is applied in the field of plastic flooring and its preparation, can solve the problems that antibacterial and antifungal properties cannot meet the needs of the market, and achieve improved appearance and life, improved temperature resistance, and improved Antimicrobial and antifungal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] An antibacterial and mildew-proof automotive interior part, made of the following raw materials by weight (kg): polycarbonate 43, triazine A resin 21, nylon 612 17, copper abietate 7, lanthanum salicylate 2, dodecahydroxy Stearic acid 8, 5-chloro-2-methyl-4-isothiazolin-3-one 9, calcium sulfite 8, dimethyl fumarate 10, diamond powder 15, o-phenylphenol 4, cyclo Barium alkanoate 2, dithiocyanomethane 7, 2-nitrobiphenyl 5.

[0015] A preparation method for an antibacterial and mildew-proof automotive interior part, comprising the following steps:

[0016] (1) Add polycarbonate, 5-chloro-2-methyl-4-isothiazolin-3-one, o-phenylphenol, 2-nitrobiphenyl into the high-speed mixer, and heat at 55-65°C Mix at high speed for 8-12 minutes, then add calcium sulfite and copper abietate, mix at 60-70°C for 7-10 minutes at high speed, cool to room temperature, and discharge to obtain mixture A;

[0017] (2) Add triazine A resin, nylon 612, dimethyl fumarate, and dithiocyanomethane in...

Embodiment 2

[0021] An antibacterial and mildew-proof automotive interior part, made of the following raw materials by weight (kg): polycarbonate 51, triazine A resin 29, nylon 612 23, copper abietate 10, lanthanum salicylate 3, dodecahydroxy Stearic acid 9, 5-chloro-2-methyl-4-isothiazolin-3-one 11, calcium sulfite 10, dimethyl fumarate 13, diamond powder 18, o-phenylphenol 6, cyclo Barium alkanoate 2.5, dithiocyanomethane 8, 2-nitrobiphenyl 7.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] An antibacterial and mildew-proof automotive interior part, made of the following raw materials by weight (kg): polycarbonate 57, triazine A resin 36, nylon 612 30, copper abietate 13, lanthanum salicylate 4, dodecahydroxy Stearic acid 10, 5-chloro-2-methyl-4-isothiazolin-3-one 14, calcium sulfite 12, dimethyl fumarate 15, diamond powder 20, o-phenylphenol 8, cyclo Barium alkanoate 3, dithiocyanomethane 9, 2-nitrobiphenyl 8.

[0025] The preparation method is the same as in Example 1.

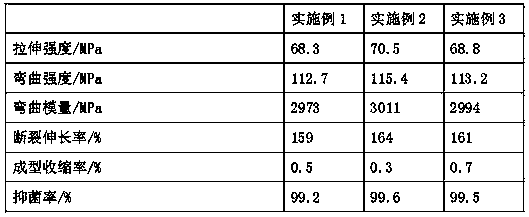

[0026] The performance test results of the plastic interior parts made by above-mentioned embodiment 1-3 are shown in the following table:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com