Copper-based catalyst for synthesis of 2, 3-dihydrofuran, preparation method and application thereof

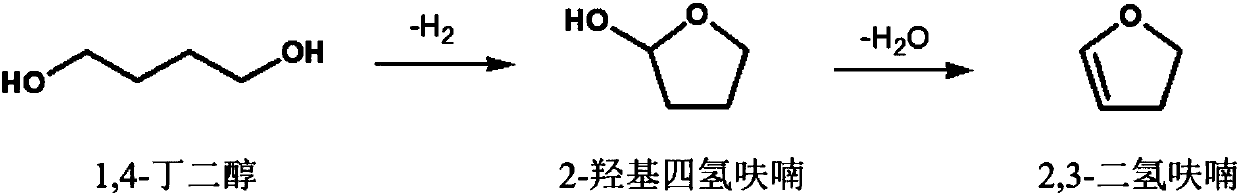

A technology of copper-based catalysts and dihydrofuran, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of long production process routes, high production costs, Complicated operation and other problems, to achieve the effect of reducing production costs, high selectivity, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

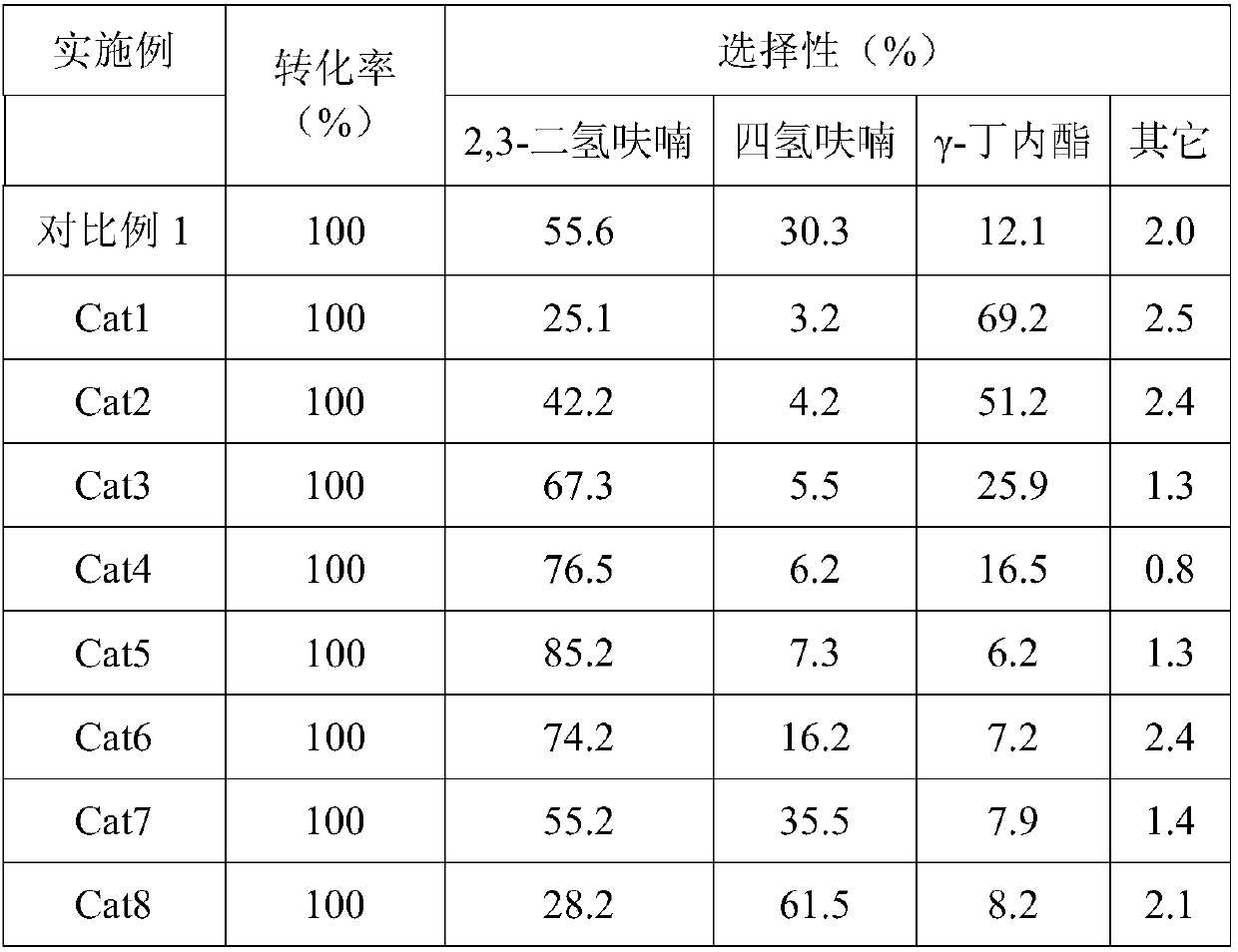

Embodiment 1

[0069] Based on the total amount of catalyst: CuO content is 50%, SiO 2 The content is 45%, Al 2 o 3 The content is 5%. Prepare a copper nitrate and aluminum nitrate mixed solution according to the proportions of the catalyst components, wherein the total concentration of metal ions is 1mol / L, then add acidic silica sol, stir and mix evenly to obtain a mixed acid solution. Then prepare 1mol / L sodium carbonate solution as lye. Under the condition of strong stirring, add the above-mentioned acid solution and alkaline solution into the precipitation tank side-by-side to carry out co-precipitation. During the precipitation process, the pH value is controlled to be 7-8, and the precipitation temperature is 60-80°C. After the precipitation, aged for 12 hours, then filtered, washed 5 times, dried at 120°C for 12h, and calcined at 450°C for about 4 hours to obtain CuO / SiO 2 -Al 2 o 3 catalyst. Catalyst labeled as Cat1 reaction results are shown in Table 1.

Embodiment 2

[0071] Based on the total amount of catalyst: CuO content is 50%, SiO 2 Content is 40%, Al 2 o 3 The content is 10%. Prepare a copper nitrate and aluminum nitrate mixed solution according to the proportions of the catalyst components, wherein the total concentration of metal ions is 1mol / L, then add acidic silica sol, stir and mix evenly to obtain a mixed acid solution. Then prepare 1mol / L sodium carbonate solution as lye. Under the condition of strong stirring, add the above-mentioned acid solution and alkaline solution into the precipitation tank side-by-side to carry out co-precipitation. During the precipitation process, the pH value is controlled to be 7-8, and the precipitation temperature is 60-80°C. After the precipitation, aged for 12 hours, then filtered, washed 5 times, dried at 120°C for 12h, and calcined at 450°C for about 4 hours to obtain CuO / SiO 2 -Al 2 o 3 catalyst. Catalyst labeled as Cat2 reaction results are shown in Table 1.

Embodiment 3

[0073] Based on the total amount of catalyst: CuO content is 50%, SiO 2 Content is 35%, Al 2 o 3 The content is 15%. Prepare a copper nitrate and aluminum nitrate mixed solution according to the proportions of the catalyst components, wherein the total concentration of metal ions is 1mol / L, then add acidic silica sol, stir and mix evenly to obtain a mixed acid solution. Then prepare 1mol / L sodium carbonate solution as lye. Under the condition of strong stirring, add the above-mentioned acid solution and alkaline solution into the precipitation tank side-by-side to carry out co-precipitation. During the precipitation process, the pH value is controlled to be 7-8, and the precipitation temperature is 60-80°C. After the precipitation, aged for 12 hours, then filtered, washed 5 times, dried at 120°C for 12h, and calcined at 450°C for about 4 hours to obtain CuO / SiO 2 -Al 2 o 3 catalyst. The catalyst is marked as Cat3 and the reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com