Permeable hydrophobic multifunctional novel waterproof coating and preparation method and applications thereof

A waterproof coating and hydrophobic technology, applied in the field of coatings, can solve the problems of poor waterproofness and permeability resistance, anti-corrosion of reinforced structure, high price of fullerenes, etc., and achieve high compressive strength, large hydrophobic angle, impermeability and waterproofing. The effect of superior ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A novel waterproof coating with penetrating hydrophobicity and multifunctionality, comprising the following components by weight:

[0057]

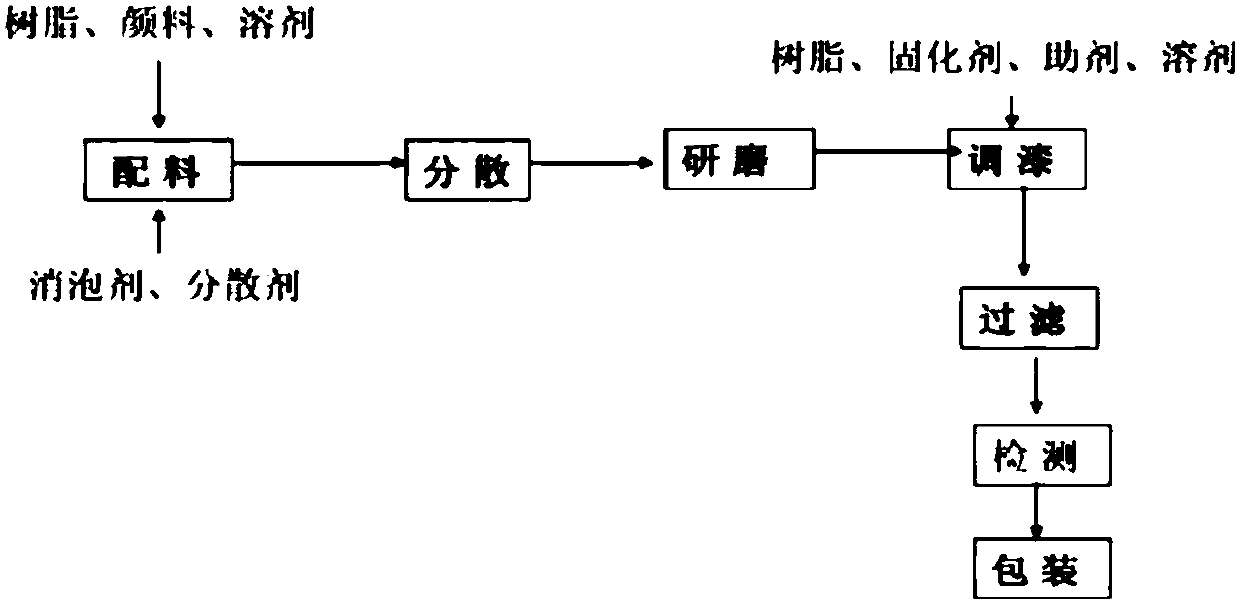

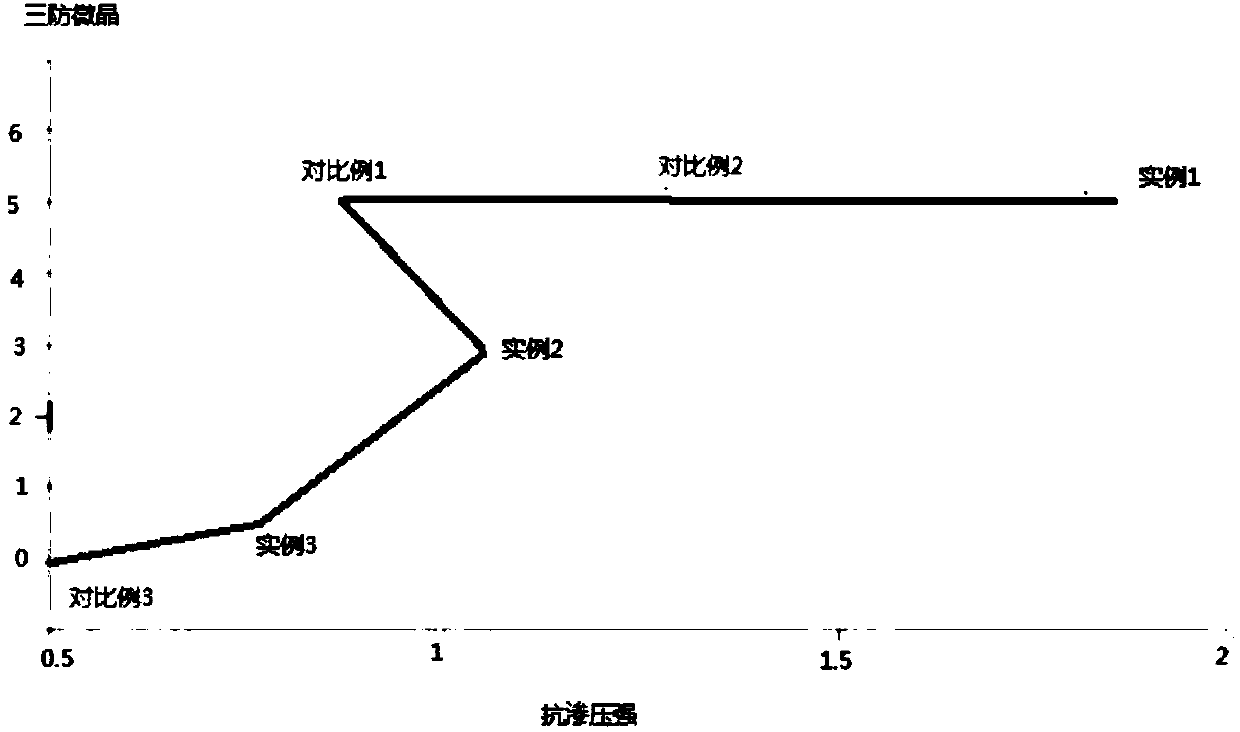

[0058] The preparation process of the above-mentioned penetrating hydrophobic multifunctional new waterproof coating is as follows: first, 128 epoxy resin, SH-023-7 silicone epoxy resin, three anti-microcrystalline, anatase titanium dioxide, carbon black powder, fumed silica R -972, active diluent BGE, toughening agent CMP-410, glass powder are added to the disperser for about 30 minutes to disperse, and then ground by a grinder until the fineness is less than 35 microns, and then polydimethylsilane is added Resin, KH-560, EFKA-5065, raybo85, dispersed for about 30 minutes, then adjusted to cement gray, filtered, packaged.

Embodiment 2

[0060] A novel waterproof coating with penetrating hydrophobicity and multifunctionality, comprising the following components by weight:

[0061]

[0062]

[0063] The preparation process of the above-mentioned permeable hydrophobic multifunctional new waterproof coating is as follows: first, 128 epoxy resin, SH-023-7 silicone epoxy resin, three anti-microcrystalline, anatase titanium dioxide, carbon black powder, fumed silica R -972, active diluent BGE, toughening agent CMP-410, glass powder are added to the disperser for about 30 minutes to disperse, and then ground by a grinder until the fineness is less than 35 microns, and then polydimethylsilane is added Resin, KH-560, EFKA-5065, raybo85, dispersed for about 30 minutes, then adjusted to cement gray, filtered, packaged.

Embodiment 3

[0065] A novel waterproof coating with penetrating hydrophobicity and multifunctionality, comprising the following components by weight:

[0066]

[0067] The preparation process of the above-mentioned penetrating hydrophobic multifunctional new waterproof coating is as follows: first, 128 epoxy resin, SH-023-7 silicone epoxy resin, three anti-microcrystalline, anatase titanium dioxide, carbon black powder, fumed silica R -972, active diluent BGE, toughening agent CMP-410, glass powder are added to the disperser for about 30 minutes to disperse, and then ground by a grinder until the fineness is less than 35 microns, and then polydimethylsilane is added Resin, KH-560, EFKA-5065, raybo85, dispersed for about 30 minutes, then adjusted to cement gray, filtered, packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com