Emollient shower gel and preparation method thereof

A technology of shower gel and deer medicine, which is applied in the field of daily chemicals, can solve the problems of patients with poor conditions, and achieve the effect of no toxic side effects and soothing skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

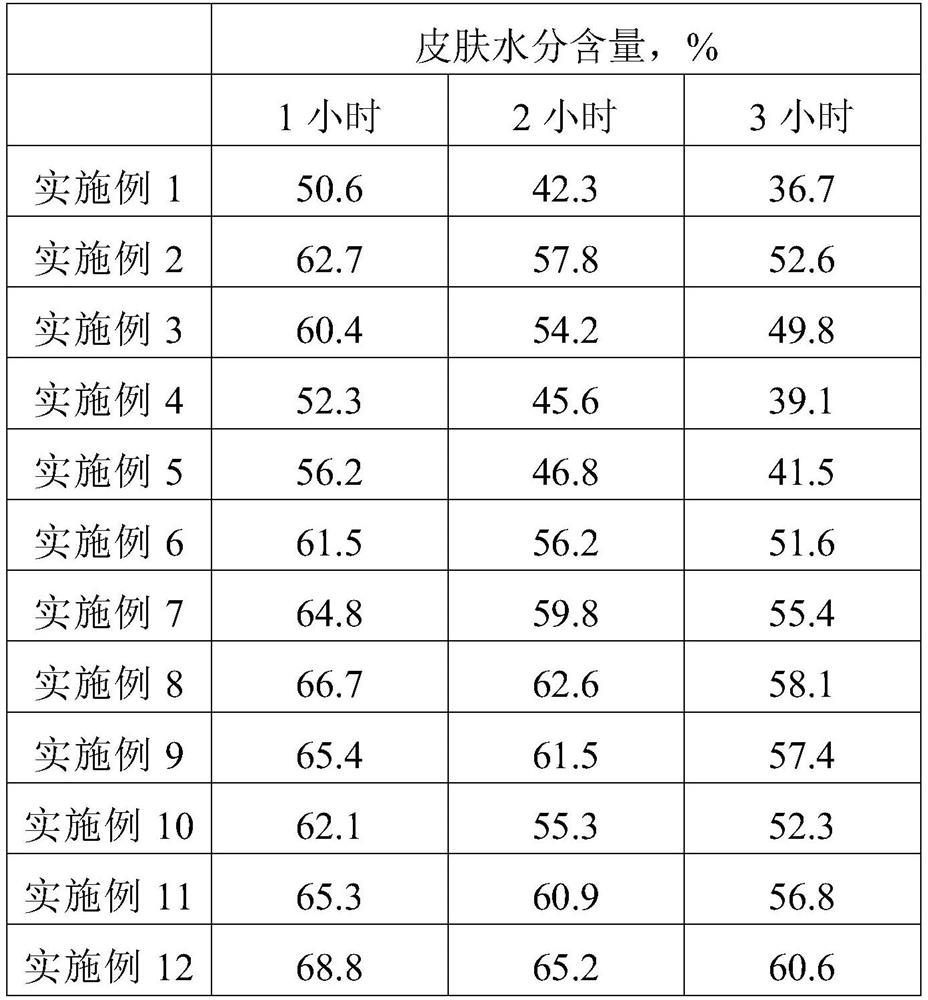

Examples

Embodiment 1

[0046] Raw materials (parts by weight): 8 parts of decyl glucoside, 3 parts of tea saponin, 3 parts of cocamidopropyl betaine, 3 parts of sodium lauryl sulfate, 1 part of trimethylglycine, 2 parts of sodium hyaluronate, 1 part of sodium carboxymethylcellulose, 0.1 part of fungicide, 78.9 parts of deionized water.

[0047] The bactericide is N, O-carboxymethyl chitosan.

[0048] The preparation method of described N, O-carboxymethyl chitosan comprises the following steps:

[0049] (1) Take 5g of chitosan, add it to 50mL of solvent, and stir at 150 rpm at 30°C for 50 minutes to obtain a mixed solution;

[0050] (2) 25mL mass fraction of 50% sodium hydroxide aqueous solution is added to the mixed solution, and stirred at 150 rpm for 90 minutes at 30°C to obtain an alkalized chitosan solution;

[0051] (3) 25g of chloroacetic acid is added to the alkalized chitosan solution, heated to 60°C, stirred at 150 rev / min for 4 hours, and vacuum filtered at a vacuum of 0.05MPa, with a fi...

Embodiment 2

[0058] Raw materials (parts by weight): 8 parts of deer medicine extract, 8 parts of decyl glucoside, 3 parts of tea saponin, 3 parts of cocamidopropyl betaine, 3 parts of sodium lauryl sulfate, 1 part of trimethylglycine, 2 parts of sodium hyaluronate, 1 part of sodium carboxymethylcellulose, 0.1 part of fungicide, 70.9 parts of deionized water.

[0059] The bactericide is N, O-carboxymethyl chitosan.

[0060] The preparation method of described N, O-carboxymethyl chitosan comprises the following steps:

[0061] (1) Take 5g of chitosan, add it to 50mL of solvent, and stir at 150 rpm at 30°C for 50 minutes to obtain a mixed solution;

[0062] (2) 25mL mass fraction of 50% sodium hydroxide aqueous solution is added to the mixed solution, and stirred at 150 rpm for 90 minutes at 30°C to obtain an alkalized chitosan solution;

[0063] (3) 25g of chloroacetic acid is added to the alkalized chitosan solution, heated to 60°C, stirred at 150 rev / min for 4 hours, and vacuum filtered...

Embodiment 3

[0075] Raw materials (parts by weight): 8 parts of deer medicine extract, 8 parts of decyl glucoside, 3 parts of tea saponin, 3 parts of cocamidopropyl betaine, 3 parts of sodium lauryl sulfate, 1 part of trimethylglycine, 2 parts of sodium hyaluronate, 1 part of sodium carboxymethylcellulose, 0.1 part of fungicide, 70.9 parts of deionized water.

[0076] The bactericide is N, O-carboxymethyl chitosan.

[0077] The preparation method of described N, O-carboxymethyl chitosan comprises the following steps:

[0078] (1) Take 5g of chitosan, add it to 50mL of solvent, and stir at 150 rpm at 30°C for 50 minutes to obtain a mixed solution;

[0079] (2) 25mL mass fraction of 50% sodium hydroxide aqueous solution is added to the mixed solution, and stirred at 150 rpm for 90 minutes at 30°C to obtain an alkalized chitosan solution;

[0080] (3) 25g of chloroacetic acid is added to the alkalized chitosan solution, heated to 60°C, stirred at 150 rev / min for 4 hours, and vacuum filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com