Paint remover

A paint remover and solvent oil technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of undisclosed paint removal, etc., and achieve the effect of improving storage stability, improving stability, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

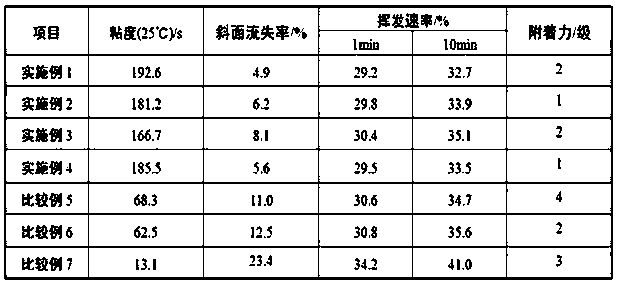

Examples

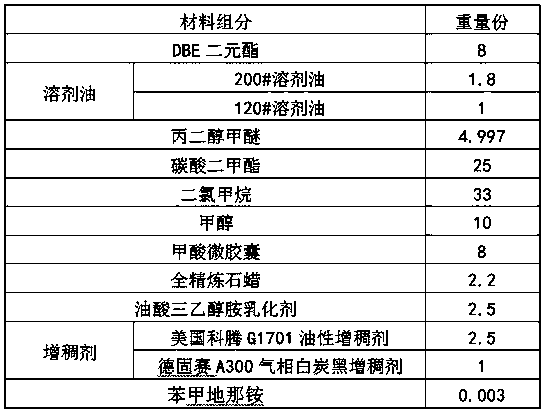

Embodiment 1

[0056] (1) Preparation method of formic acid microcapsules

[0057] a. Add 5 parts of toluene and 1.5 parts of ethanol to a three-necked flask with a reflux device, and slowly add 7 parts of ethyl cellulose to disperse until completely dissolved in a constant temperature water bath at 70-75°C and at a speed of 300-500r / min. Disperse for 5 to 10 minutes to obtain a dispersion; then slowly add a mixture of 18 parts of formic acid and 27 parts of curing agent urea into the dispersion; slowly add non-solvent petroleum ether under stirring until the ethyl cellulose coagulates, stop heating; place, naturally cool to room temperature, filter, wash, and dry to obtain ethylcellulose-coated microcapsules.

[0058] b. Put 20 parts of water into the three-necked flask, heat it to 60°C, slowly add 6 parts of sodium alginate while stirring, after the sodium alginate is completely dissolved, add 18 parts of microcapsules coated with ethyl cellulose, and continue stirring After 10 minutes, s...

Embodiment 2

[0064] (1) The preparation method of formic acid microcapsules: except that 8 parts of toluene and 9 parts of ethyl cellulose are used, the remaining components are the same as in (1) in Example 1.

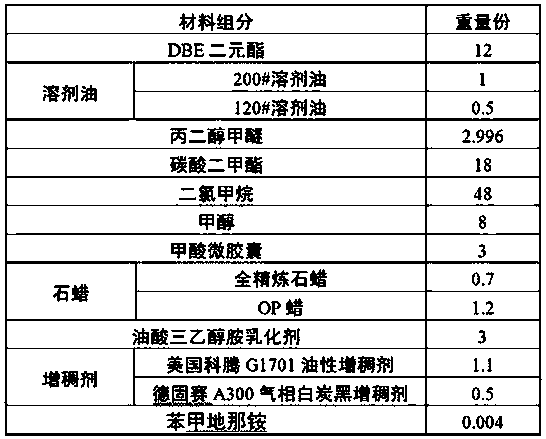

[0065] (2) A paint remover whose formula comprises by weight:

[0066]

[0067] In this example, 100 parts of paint remover can also be filled into the aerosol can, after vacuuming, valve opening and sealing, 6 parts of carbon dioxide and 22 parts of HFO-1234ze propellant can be filled, and the head can be installed Get an aerosol paint remover.

[0068] In other embodiments, the propellant can also be 8 parts carbon dioxide, 12 parts HFO-1234ze, or 10 parts carbon dioxide, 5 parts HFO-1234ze.

Embodiment 3

[0070] (1) The preparation method of formic acid microcapsules: except that 7 parts of toluene and 10 parts of ethyl cellulose were used, the remaining components were the same as in (1) in Example 1.

[0071] (2) A paint remover whose formula comprises by weight:

[0072]

[0073] In this example, it is also possible to fill 100 parts of paint remover into the aerosol can, after vacuuming, releasing the valve and sealing, fill 6 parts of carbon dioxide, 22 parts of HFO-1234yf propellant, and press the head. Get an aerosol paint remover.

[0074] In other embodiments, the propellant can also be 8 parts of carbon dioxide, 12 parts of HFO-1234yf, or 10 parts of carbon dioxide, 5 parts of HFO-1234yf.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com