Preparation method of antifriction and antiwear coating layer under MoDTC lubricating condition

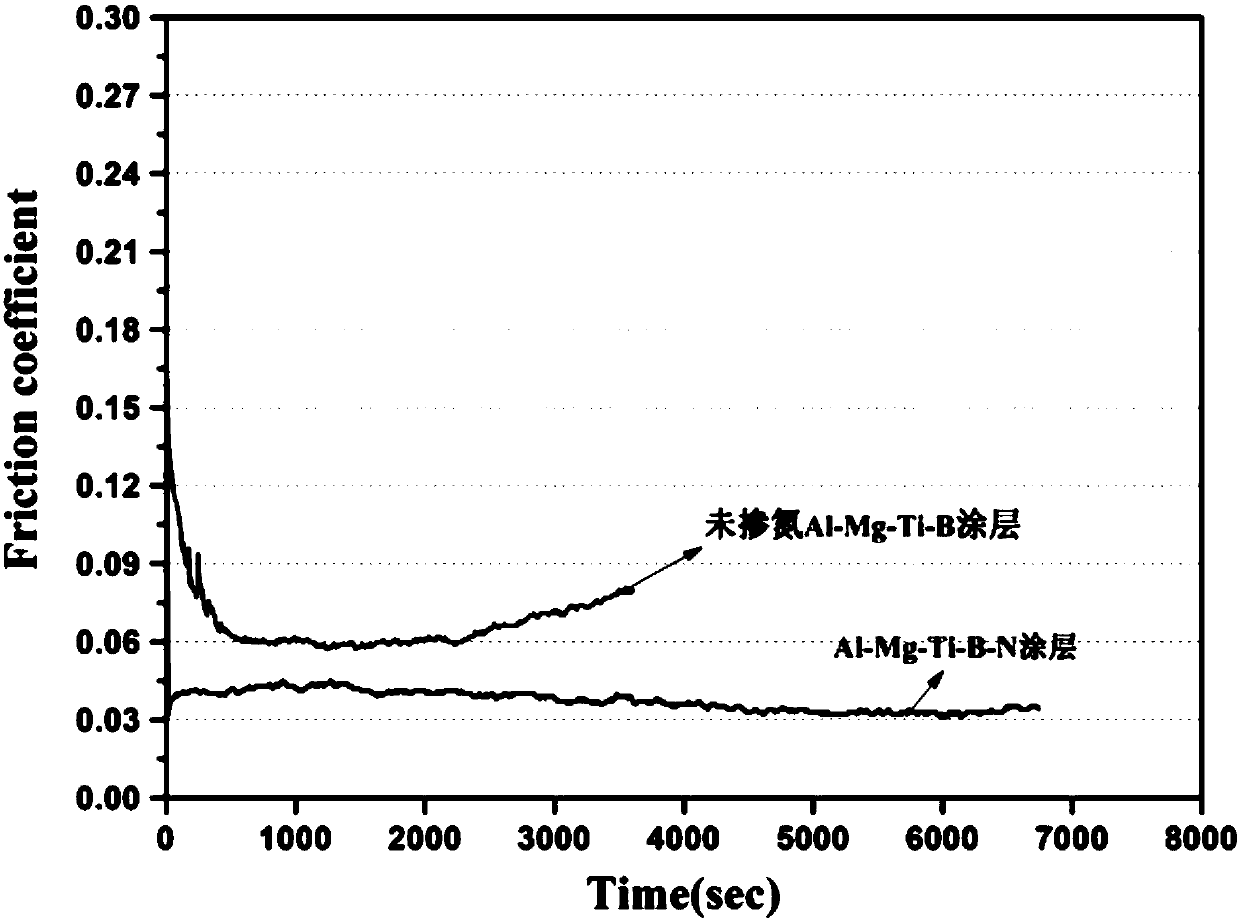

A coating and condition technology, applied in the field of surface engineering and wear-resistant coating materials, can solve the problems of increased friction coefficient, increased wear, and resource loss, achieving low friction coefficient, reduced emissions, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Coating preparation method steps

[0036] (1) Substrate cleaning

[0037] Bearing steel is used as the coating base, and the base is treated with descaling water for 6-8 hours, cleaned with deionized water and soaked in anti-rust water for one night. The bearing steel treated with de-scaling and anti-rust water uses acetone and ethanol Sonicate for 5-10min and dry with high-purity nitrogen. Put the substrate rack on the sample tray rack of the vacuum chamber, close the chamber, and vacuum the back to 7.8×10 -4 Pa, and then 45 sccm argon gas was introduced into the system, and the air pressure was maintained at ~2.3 Pa, and a 700V bias voltage was applied to the substrate for backsputter cleaning for 30 minutes.

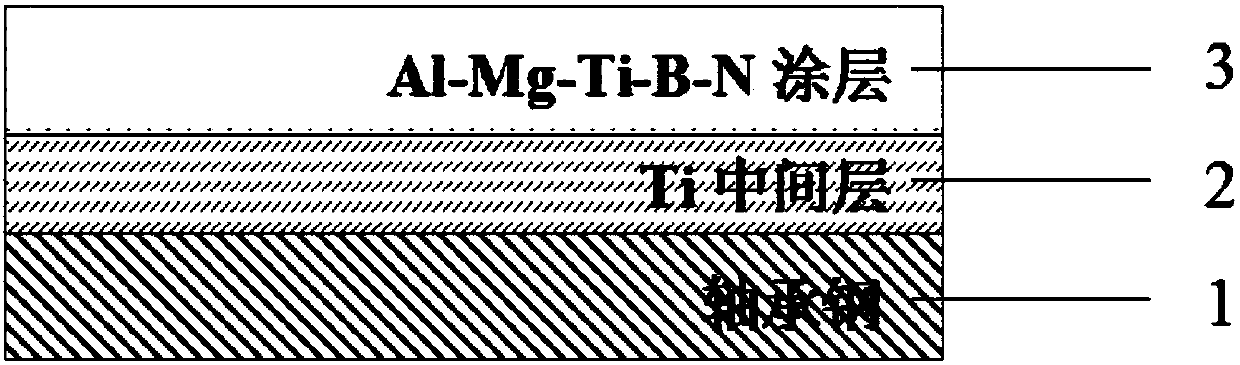

[0038] (2) Ti-plated intermediate layer

[0039] A Ti intermediate layer was plated on the surface of the substrate by DC magnetron sputtering. A metal Ti target is used, the sputtering atmosphere is Ar, the Ar gas flow is controlled at 30-50 sccm, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com