System and method for preventing ammonium bisulfate from blocking air preheater after SCR denitration modification

An air preheater and ammonium bisulfate technology, applied in preheating, combustion methods, feed water heaters, etc., can solve problems such as blockage of air preheater, ABS corrosion, etc., to avoid corrosion and ash blocking, and save coal consumption for power supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

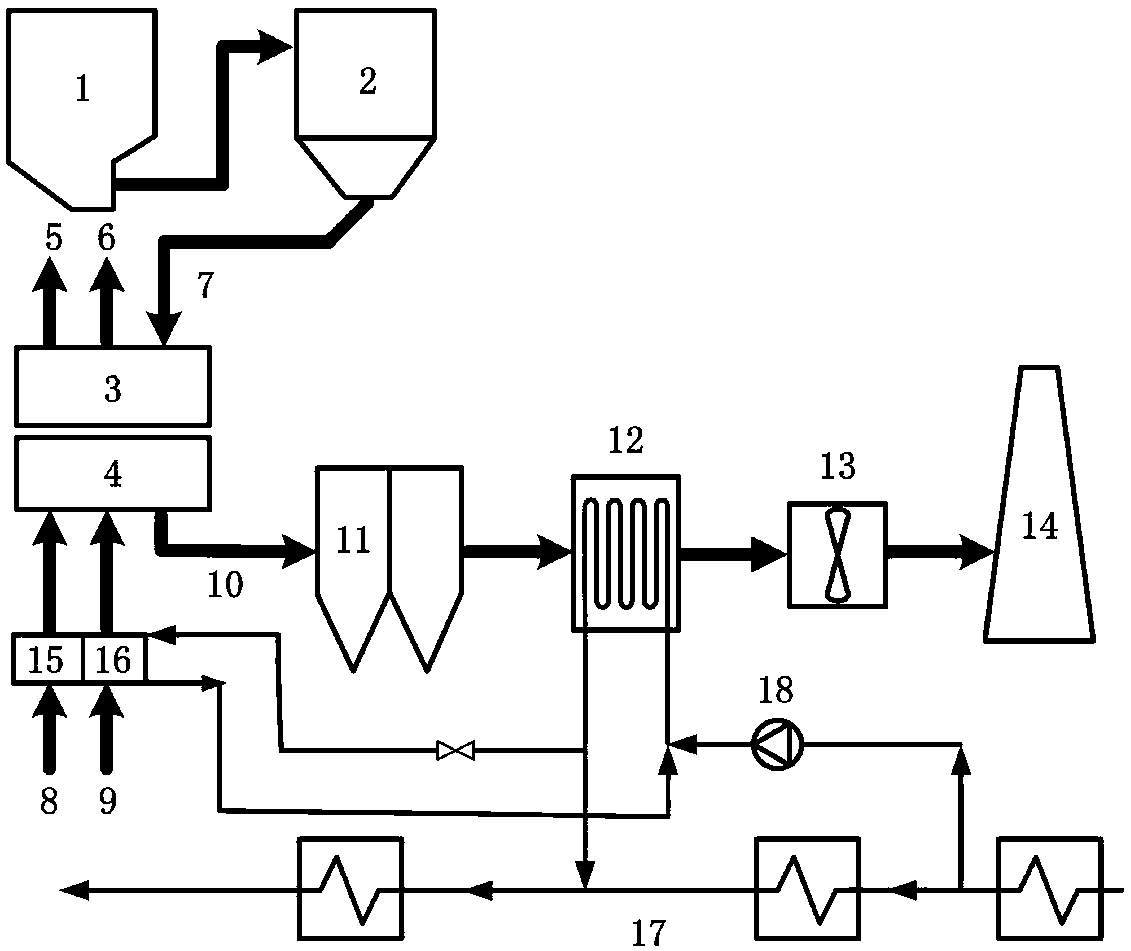

[0031] Such as figure 1 As shown, the system for preventing ammonium bisulfate from clogging the air preheater after SCR denitrification transformation in this embodiment includes: passing through the coal-fired boiler 1, SCR denitrification device 2, rotary air preheater, and dust collector in sequence along the flue gas flow direction. device 11, low-pressure low-temperature economizer 12, induced draft fan 13 and chimney 14. The rotary air preheater is composed of the high temperature section 3 of the rotary air preheater and the medium temperature section 4 of the rotary air preheater. The medium temperature section 4 of the rotary air preheater is provided with an air preheater outlet flue 10 As well as the cold primary air duct 8 and the cold secondary air duct 9, the high temperature section 3 of the rotary air preheater is provided with an air preheater inlet flue 7, a hot primary air duct 5 and a hot secondary air duct 6. A primary air heater 15 and a secondary air h...

Embodiment 2

[0034] The method for preventing ammonium bisulfate from blocking the air preheater after SCR denitrification transformation in this embodiment is applicable to the system for preventing ammonium bisulfate from blocking the air preheater after SCR denitration transformation described in Example 1. The method includes: The flue gas output from the coal boiler passes through the SCR denitrification device, air preheater, dust collector, low-pressure low-temperature economizer, induced draft fan, and chimney in sequence;

[0035] An air heater is installed on the cold primary air duct of the air preheater. After the heating surface of the air preheater is reduced, when the cold primary air duct heater is not put into operation, the outlet air temperature of the hot primary air duct can reach about 230°C-240°C. Therefore, when the boiler burns coal with low moisture , the hot primary air can meet the drying output of the milling system without mixing cold air. However, when the b...

Embodiment 3

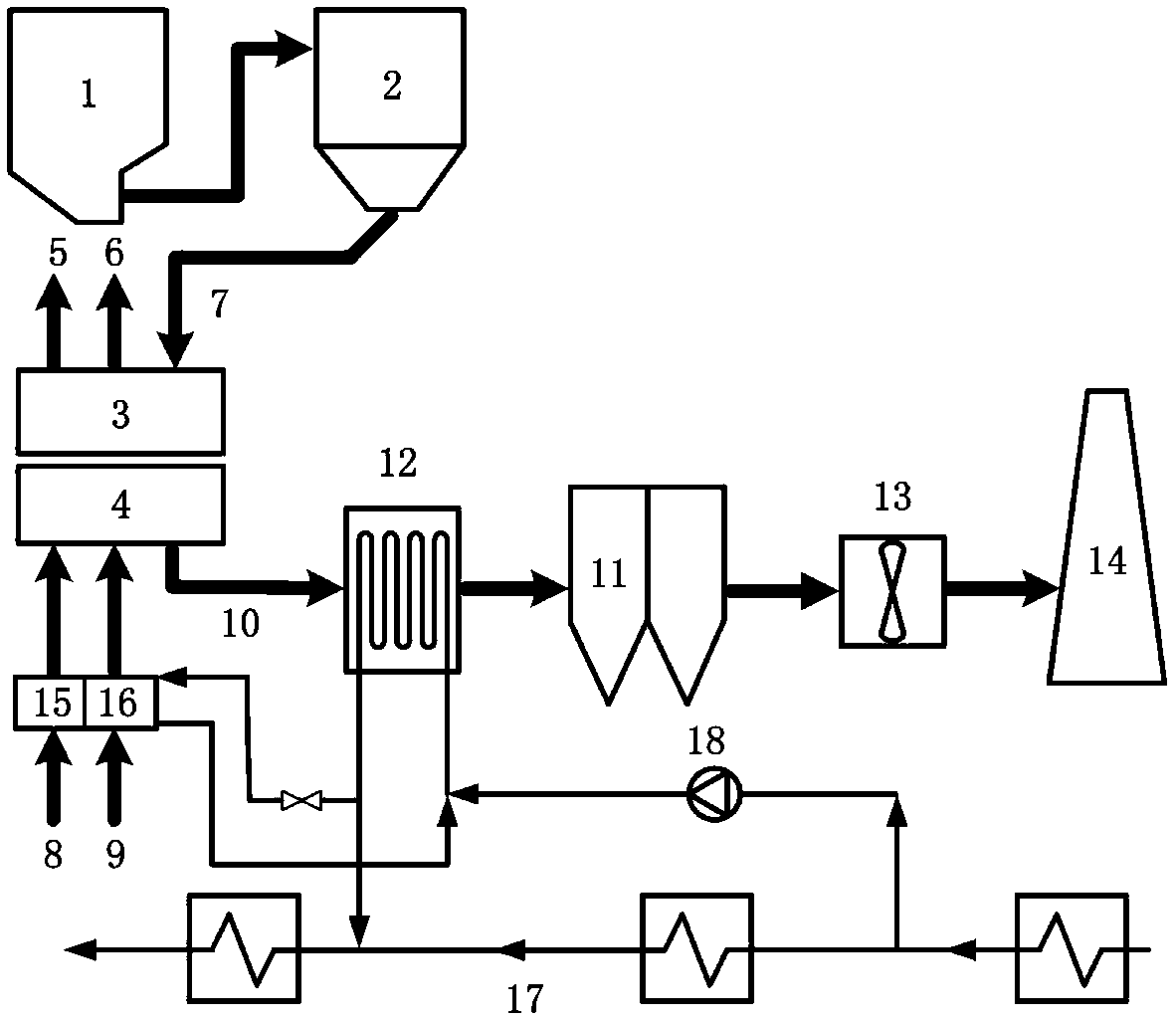

[0039] Such as figure 2 As shown, the system for preventing ammonium bisulfate from clogging the air preheater after the SCR denitrification transformation in this embodiment includes: passing through the coal-fired boiler 1, the SCR denitrification device 2, the rotary air preheater, the low-pressure Low temperature economizer 12, dust collector 11, induced draft fan 13 and chimney 14. The rotary air preheater is composed of the high temperature section 3 of the rotary air preheater and the medium temperature section 4 of the rotary air preheater. The medium temperature section 4 of the rotary air preheater is provided with an air preheater outlet flue 10 As well as the cold primary air duct 8 and the cold secondary air duct 9, the high temperature section 3 of the rotary air preheater is provided with an air preheater inlet flue 7, a hot primary air duct 5 and a hot secondary air duct 6. A primary air heater 15 and a secondary air heater 16 are respectively installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com