Wastewater purification and discharge treatment equipment

A technology for treatment equipment and wastewater purification, which is applied in the field of wastewater purification and discharge treatment equipment, can solve the problems of large dosage of drugs, difficult precipitation, and large labor consumption, and achieves the effects of safe discharge, pollution reduction, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

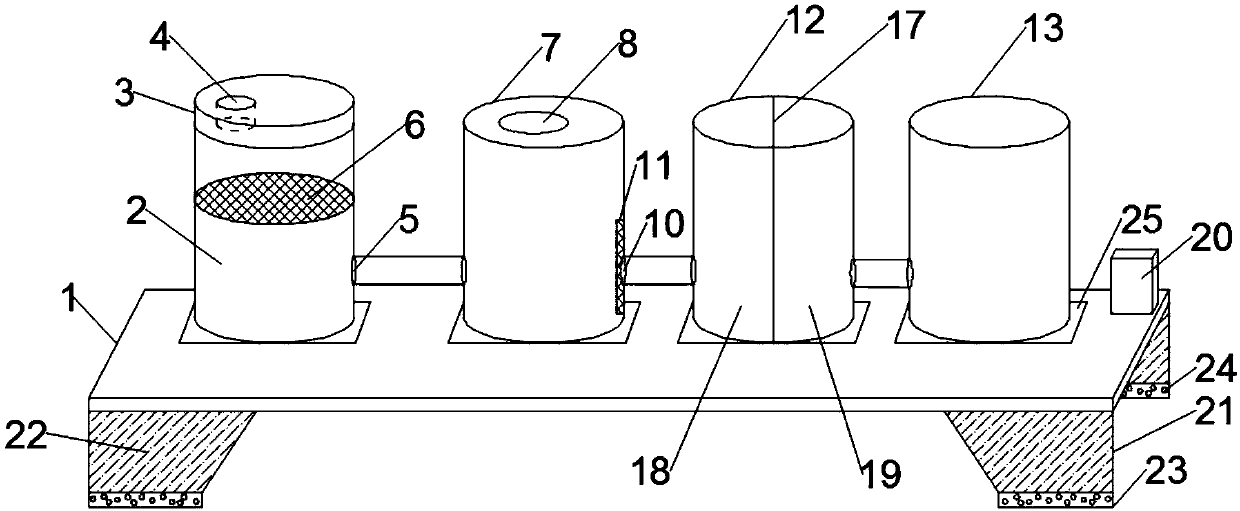

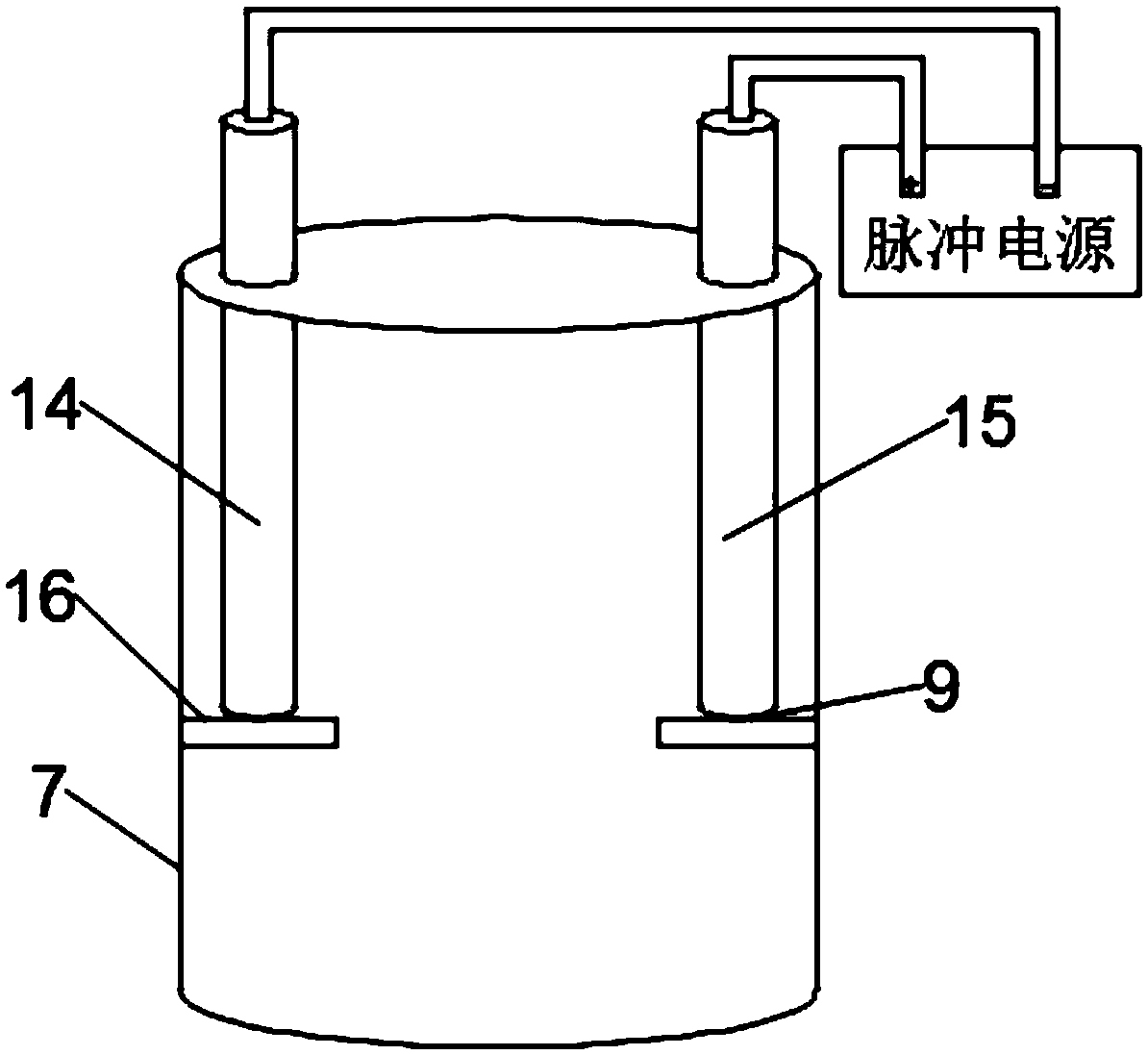

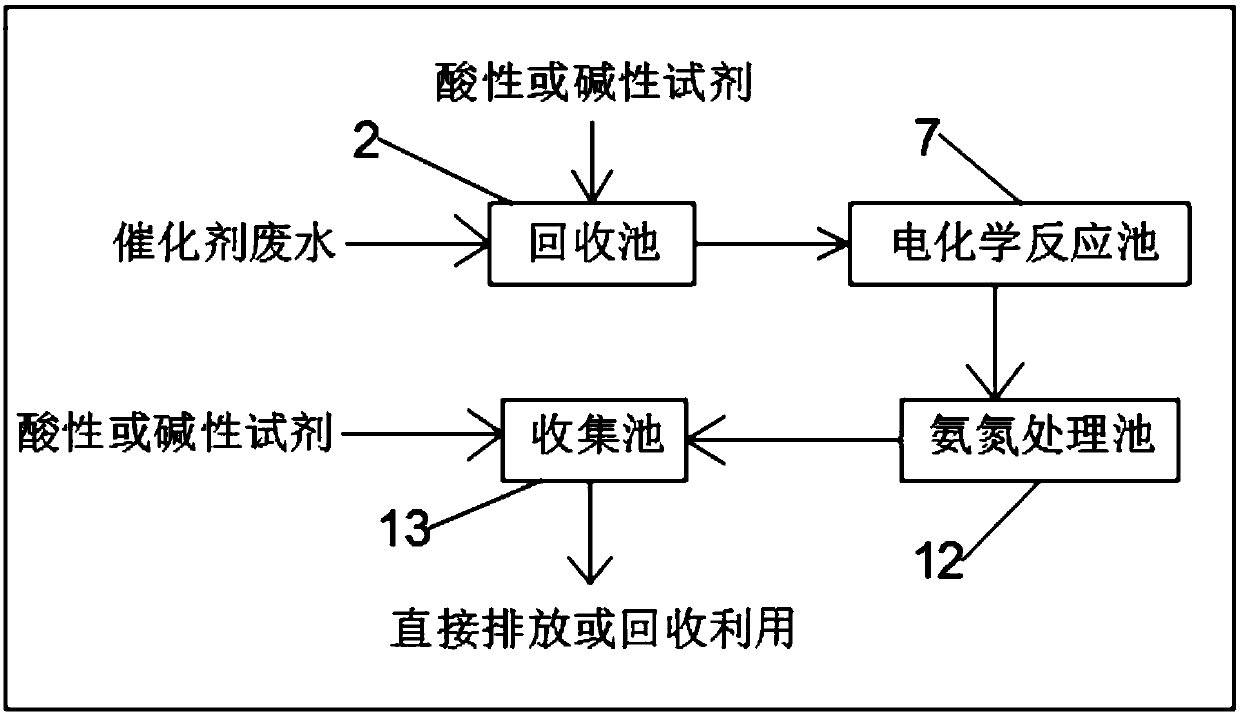

[0023] Such as figure 1 and image 3 As shown, a waste water purification and discharge treatment equipment includes a base 1, the upper surface of the base 1 is provided with a recovery pool 2, the top of the recovery pool 2 is provided with a cover 3, and the surface of the cover 3 is provided with an inlet The water outlet 4, the recovery pool 2 recycles the waste water produced by chemical production through the water inlet 4, the right end of the recovery pool 2 is provided with a sewage outlet 5, and the inside of the recovery pool 2 is provided with a horizontal first filter screen 6 , the first filter screen 6 is fixed together with the inner wall of the recovery pool 2 by screws, the sewage outlet 5 is connected with an electrochemical reaction cell 7 through a pipeline, and the electrochemical reaction cell 7 is arranged on the upper surface of the base 1, The top of the electrochemical reaction cell 7 is provided with a feeding port 8, through which an acidic or al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com