Modified graphene cement-based composite material, and preparation and application of material

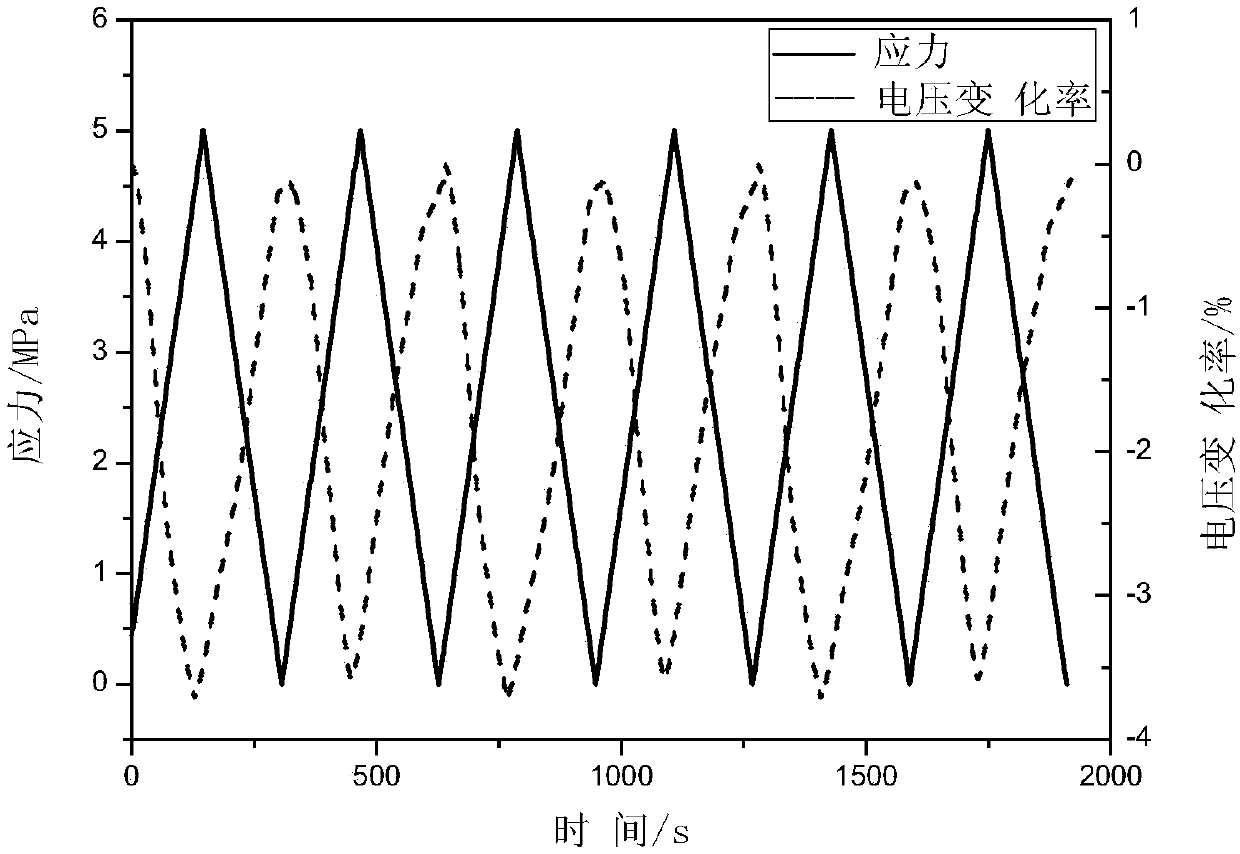

A composite material and graphene technology, applied in the direction of instruments, measuring devices, measuring force, etc., can solve problems such as easy agglomeration, poor hydrophilicity of graphene, and inability to improve the performance of cement-based materials, etc., to achieve good dispersion and sensory sensitivity The effect of high and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: cement-based material without adding modified graphene

[0037] Add 202.5g of water to 450g of cement, use a mortar mixer to stir slowly until uniform, slowly add 1350g of standard sand and continue to stir evenly, pour it into the mold, lightly vibrate until it is dense, and standardize for 28 days.

[0038] The modified graphene cement-based composite material has a compressive strength of 55MPa and a flexural strength of 8.2MPa.

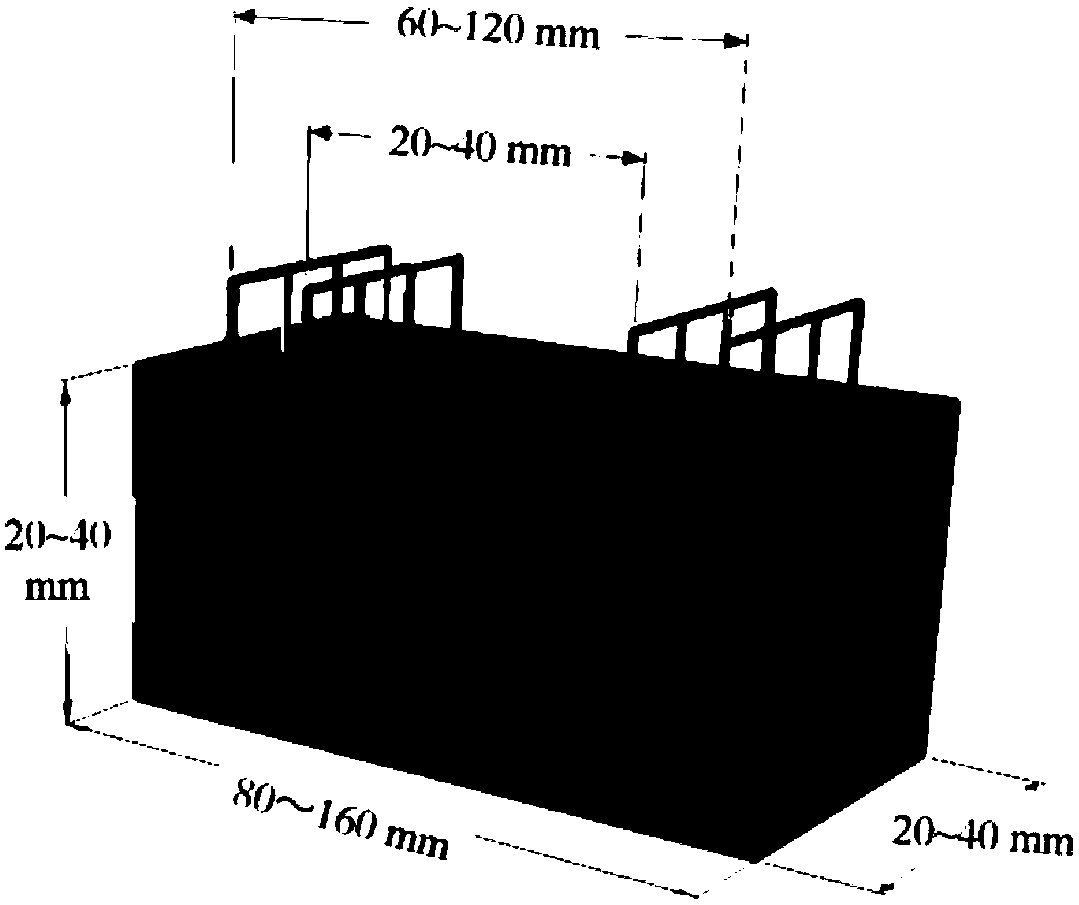

[0039] In size 80 x 40 x 40mm 3 Four electrodes are embedded in the graphene cement-based composite test block to obtain a pressure sensitive sensor, and the four electrodes are distributed on the same surface of the test block in sequence from left to right, and distributed symmetrically with the central axis of the test block surface, forming Two internal electrodes and two external electrodes, the distance between the two internal electrodes is 40 mm, and the distance between the two external electrodes is 60 mm.

[0040]...

Embodiment 2

[0044] Embodiment 2: graphene dosage is the graphene cement-based sensor of 0.5% of cement quality

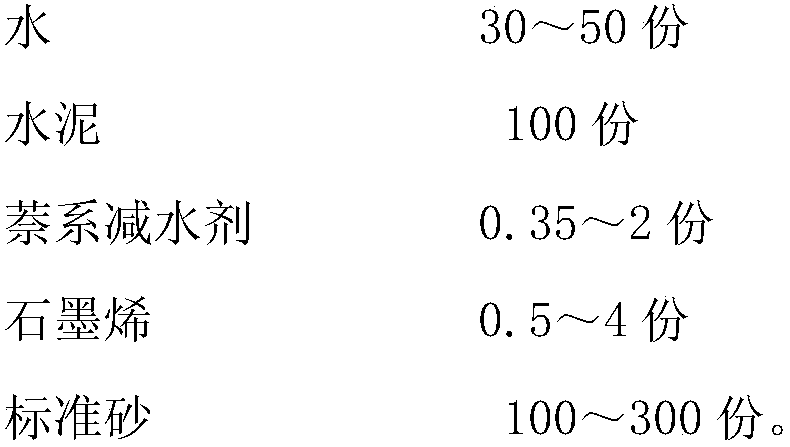

[0045] A modified graphene cement-based composite material is composed of water, cement, graphene, naphthalene-based water reducing agent (provided by Nanjing Subote New Material Co., Ltd.), and standard sand, wherein the particle size of graphene is 7-8 μm , the thickness is less than 10nm, and the specific surface area is not less than 120m 2 / g. First weigh 1.575g of naphthalene-based superplasticizer powder, mix it with 162g of water evenly, add 0.225g (cement mass 0.05%) graphene powder into the naphthalene-based superplasticizer solution, and use an ultrasonic cell pulverizer with a power of 360W to ultrasonically 10min; repeat the above steps 4 times; then add 0.225g graphene powder to the above graphene dispersion, and use an ultrasonic cell pulverizer with a power of 720W to ultrasonicate for 10min; repeat the above steps 4 times until the amount of graphene is 2.25g ...

Embodiment 3

[0052] Embodiment 3: graphene dosage is the graphene cement-based sensor of 1% of cement quality

[0053] A modified graphene cement-based composite material is composed of water, cement, graphene, naphthalene-based water reducing agent (provided by Nanjing Subote New Material Co., Ltd.), and standard sand, wherein the particle size of graphene is 7-8 μm , the thickness is less than 10nm, and the specific surface area is not less than 120m 2 / g. First weigh 2.25g of naphthalene-based superplasticizer powder, mix it with 162g of water evenly, add 0.45g (cement mass 0.1%) graphene powder into the naphthalene-based superplasticizer solution, and use an ultrasonic cell pulverizer with a power of 360W to ultrasonically 15min; repeat the above steps 4 times; then add 0.45g graphene powder to the above graphene dispersion, and use an ultrasonic cell pulverizer with a power of 720W for 30min; repeat the above steps 4 times until the graphene content is 4.5g . Finally, an ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com