Nitrogen-doped nickel cobalt oxide nanowire array and preparation method thereof

A nanowire array, nickel-cobalt-oxygen technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor cycle stability of lithium batteries, inability to insert lithium ions, and reduced capacity , achieve the effect of strong repeatability, easy large-scale production, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: 0.5g cobalt nitrate, 0.5g nickel nitrate, 0.15g ammonium fluoride, and 0.1g urea were mixed and reacted for 10 hours under hydrothermal conditions at 90°C, and nickel-cobalt-oxygen precursor nanowire arrays were grown on 2g nickel foam;

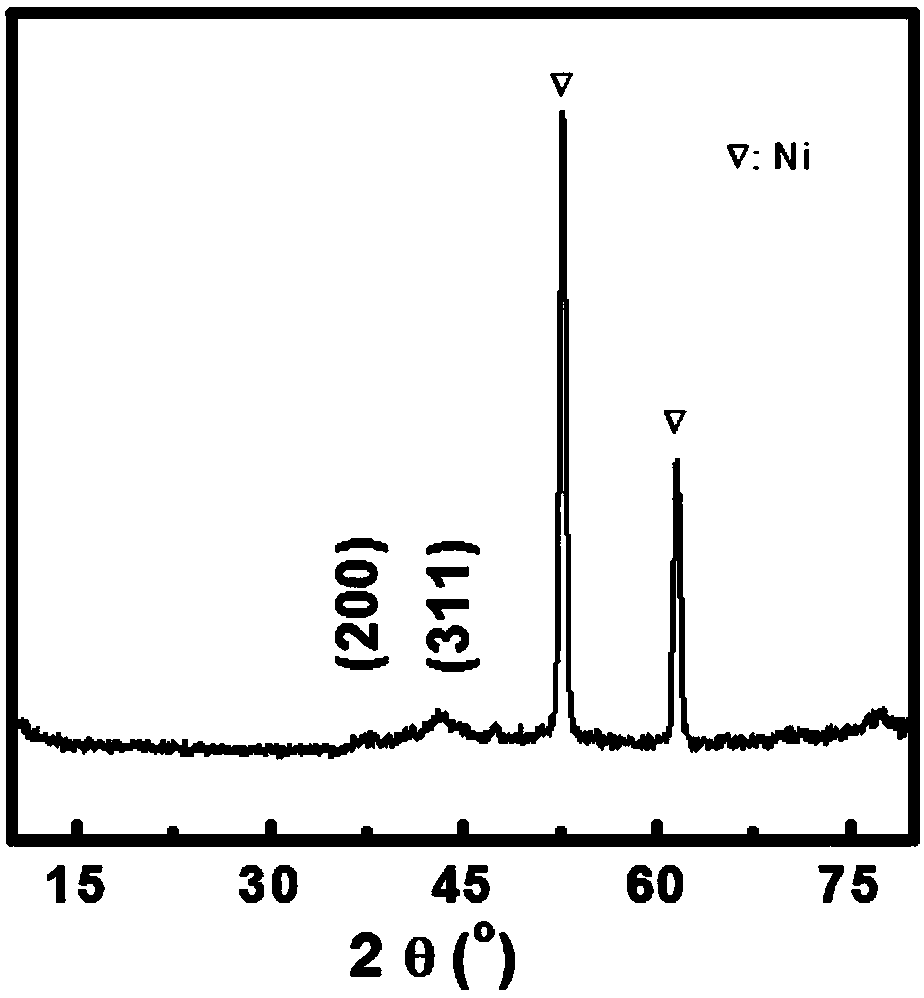

[0024] Step 2: Calcining the nickel-cobalt-oxygen precursor nanowire array at 200°C for 4 hours in an air atmosphere to synthesize NiCo 2 o 4 nanowire arrays;

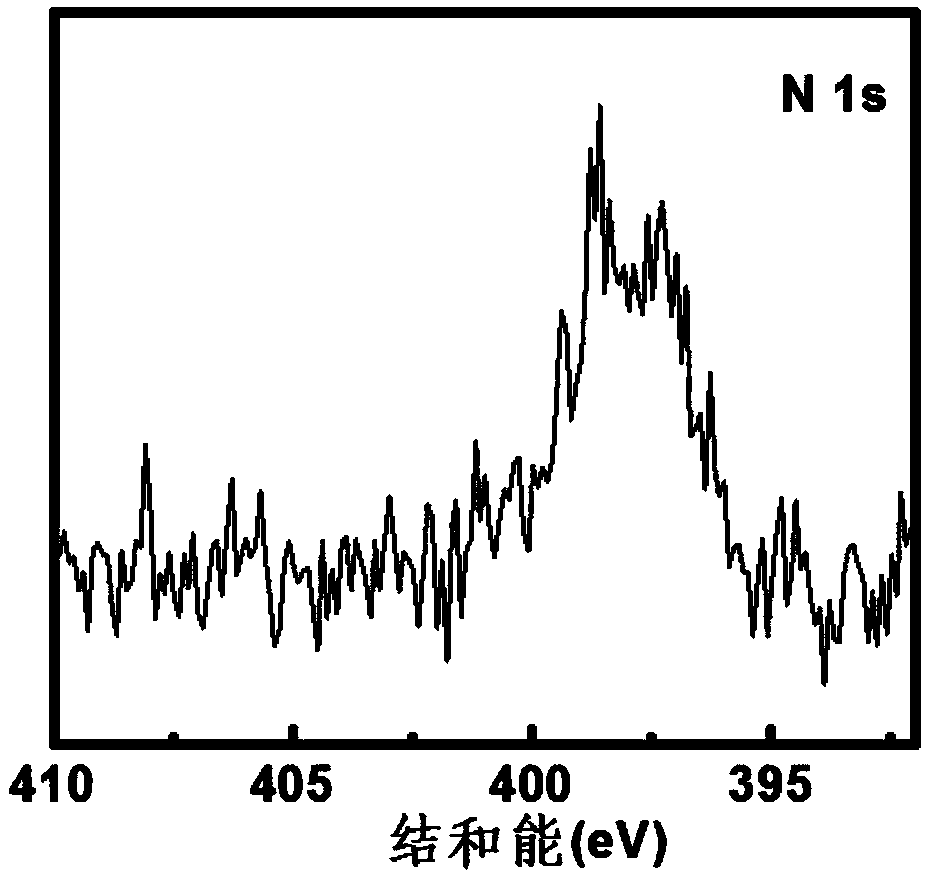

[0025] Step 3: NiCo 2 o 4 The nanowire array was calcined at 200 °C for 3 h in an ammonia atmosphere, and the NiCo grown on the nickel foam 2 o 4 The nanowire arrays are nitrogen doped.

[0026] Figure 4 It is the charge-discharge curve diagram of the nickel-cobalt-oxygen precursor nanowire array grown on the foamed nickel prepared in Example 1, by Figure 4 It can be seen that at 100mAg -1 Under the current density, the discharge specific capacity reaches 1300mAh g -1 .

Embodiment 2

[0028] Step 1: 0.3g cobalt nitrate, 0.3g nickel nitrate, 0.09g ammonium fluoride, and 0.06g urea were mixed and reacted for 9 hours under hydrothermal conditions of 110°C, and nickel-cobalt-oxygen precursor nanowire arrays were grown on 2g nickel foam;

[0029] Step 2: Calcining the nickel-cobalt-oxygen precursor nanowire array at 300°C for 3 hours in an air atmosphere to synthesize NiCo 2 o 4 nanowire arrays;

[0030] Step 3: NiCo 2 o 4 The nanowire array was calcined at 300°C for 2h in an ammonia atmosphere, and the NiCo grown on nickel foam 2 o 4 The nanowire arrays are nitrogen doped.

Embodiment 3

[0032] Step 1: Mix 0.4g cobalt nitrate, 0.4g nickel nitrate, 0.12g ammonium fluoride, and 0.08g urea for 9.5h under hydrothermal conditions at 120°C, and grow nickel-cobalt oxide precursor nanowire arrays on 2g nickel foam ;

[0033] Step 2: Calcining the nickel-cobalt-oxygen precursor nanowire array at 400°C for 5 hours in an air atmosphere to synthesize NiCo 2 o 4 nanowire arrays;

[0034] Step 3: NiCo 2 o 4 The nanowire array was calcined at 400 °C for 1.5 h in an ammonia atmosphere, and the NiCo grown on the nickel foam 2 o 4 The nanowire arrays are nitrogen doped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com