A processing method of rod-shaped mud material cutting line for daily-use ceramic blank making

A processing method and technology made of ceramics, applied in the directions of yarn, textiles, papermaking, adhesives, etc., can solve the problems of affecting the appearance quality of ceramic blanks, rust easily adhering to mud, and rod-shaped mud with low water content, etc. Achieve long service life, ensure flatness, and avoid rust problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

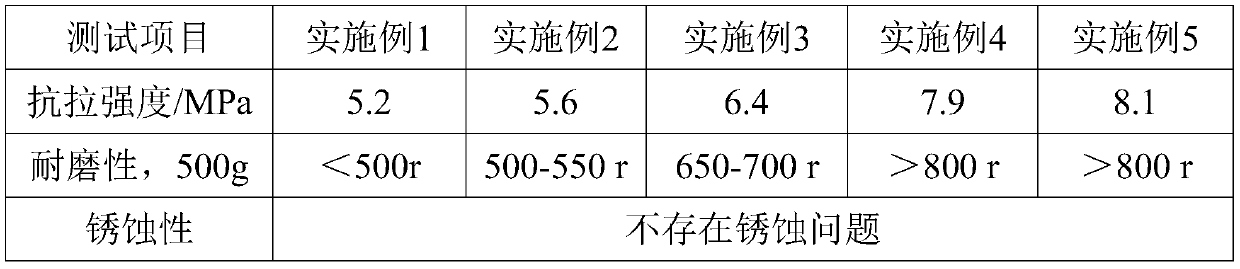

Examples

Embodiment 1

[0027] (1) Core production: 8g of aramid fiber, 1g of polyethylene fiber, and 0.5g of sepiolite fiber are fully mixed to make blended yarn through spinning process, and the blended yarn is made into a diameter of 0.25mm through parallel twisting process the wire core;

[0028] (2) Preparation of wrapping material: After fully mixing 10g chlorinated polyvinyl chloride, 5g pentaerythritol stearate, 1g bentonite, 0.5g ceramic micropowder, 1g polydipentaerythritol hexaacrylate, and 0.5g hexamethylolmelamine hexamethyl ether Send it into the kneader, and knead for 5 minutes in the molten state to obtain the wrapping material;

[0029] (3) Cutting wire forming: Add the wrapping material into the barrel of the screw extruder, and feed the wire core into the wire feeding device of the screw extruder. The molten wrapping material is evenly coated on the wire core, and the wrapping material is cooled. A wrapping layer with a thickness of 0.25 mm is formed on the wire core, and the cutt...

Embodiment 2

[0032] (1) Core production: 8g of aramid fiber, 1g of polyethylene fiber, and 0.5g of sepiolite fiber are fully mixed to make blended yarn through spinning process, and the blended yarn is made into a diameter of 0.25mm through parallel twisting process the wire core;

[0033] (2) Preparation of wrapping material: After fully mixing 10g chlorinated polyvinyl chloride, 5g pentaerythritol stearate, 1g bentonite, 0.5g ceramic micropowder, 1g polydipentaerythritol hexaacrylate, and 0.5g hexamethylolmelamine hexamethyl ether Send it into the kneader, and knead for 5 minutes in the molten state to obtain the wrapping material;

[0034] (3) Cutting wire forming: Add the wrapping material into the barrel of the screw extruder, and feed the wire core into the wire feeding device of the screw extruder. The molten wrapping material is evenly coated on the wire core, and the wrapping material is cooled. A wrapping layer with a thickness of 0.25 mm is formed on the wire core, and the cutt...

Embodiment 3

[0038] (1) Core production: 8g of aramid fiber, 1g of polyethylene fiber, and 0.5g of sepiolite fiber are fully mixed to make blended yarn through spinning process, and the blended yarn is made into a diameter of 0.25mm through parallel twisting process the wire core;

[0039] (2) Preparation of wrapping material: After fully mixing 10g chlorinated polyvinyl chloride, 5g pentaerythritol stearate, 1g bentonite, 0.5g ceramic micropowder, 1g polydipentaerythritol hexaacrylate, and 0.5g hexamethylolmelamine hexamethyl ether Send it into the kneader, and knead for 5 minutes in the molten state to obtain the wrapping material;

[0040] (3) Cutting wire forming: Add the wrapping material into the barrel of the screw extruder, and feed the wire core into the wire feeding device of the screw extruder. The molten wrapping material is evenly coated on the wire core, and the wrapping material is cooled. A wrapping layer with a thickness of 0.25 mm is formed on the wire core, and the cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com