Biomass material for solidifying quaternary ammonium salt as well as preparation method and application thereof

A technology of biomass materials and quaternary ammonium salts, applied in botany equipment and methods, chemicals for biological control, applications, etc., can solve problems such as high cost, complicated process, and secondary pollution, and achieve low cost, The effect of overcoming secondary pollution and efficient deep purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

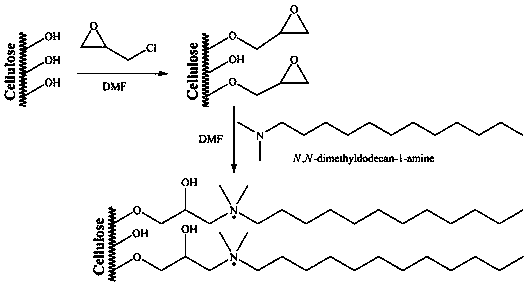

Method used

Image

Examples

Embodiment 1

[0027] Take 0.5 g of sieved wheat straw particles (0.1–0.8 mm) into a three-necked flask, add 2 mL of N-N dimethylformamide, and add 5 mL of epichlorohydrin, and stir for 0.5 h at a temperature of 30 °C . Secondly, 10 mL of octaalkyldimethyl tertiary amine was added, and the reaction was stirred at 40 °C for 1 h to prepare the biomass-based immobilized quaternary ammonium fungicide 1.

[0028] Wherein, the content of quaternary ammonium salt is 0.1 mmol / g.

[0029] Experiments show that the biomass-based immobilized quaternary ammonium salt fungicide prepared above has obvious removal effect on bacteria in water. When the solution pH is 6, E. coli content>10 4 CFU / mL, 10 g / L Material 1 can completely kill Escherichia coli and meet the national drinking water standard.

Embodiment 2

[0031] Take 2 g of sieved corn stalk particles (0.2-0.6 mm) into a three-necked flask, add 20 mL of N-N dimethylformamide, and add 20 mL of epichlorohydrin, and stir for 1.5 h at a temperature of 40 °C . Secondly, 20 mL of dedecyldimethyl tertiary amine was added, and the reaction was stirred at 50 °C for 1.5 h to prepare the biomass-based immobilized quaternary ammonium fungicide 2.

[0032] Wherein, the content of quaternary ammonium salt is 0.15 mmol / g.

[0033] Experiments show that the biomass-based immobilized quaternary ammonium salt fungicide prepared above has obvious removal effect on bacteria in water. When the solution pH is 5, E. coli content>10 5 CFU / mL, 5 g / L Material 2 can completely kill Escherichia coli and meet the national drinking water standard.

Embodiment 3

[0035] Take 5 g of sieved wheat straw particles (0.5–0.8 mm) into a three-necked flask, add 50 mL of N-N dimethylformamide, and add 50 mL of epichlorohydrin, and stir the reaction at 60 °C for 2 h . Secondly, 20 mL of dodecyl dimethyl tertiary amine was added, and stirred at 60 °C for 2 h to prepare biomass-based immobilized quaternary ammonium fungicide 3.

[0036] Wherein, the content of quaternary ammonium salt is 0.3 mmol / g.

[0037] Experiments show that the biomass-based immobilized quaternary ammonium salt fungicide prepared above has obvious removal effect on bacteria in water. When the solution pH is 6.5, E. coli content>10 5 CFU / mL, 4 g / L Material 3 can completely kill Escherichia coli and meet the national drinking water standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com