Preparation method of high-light-resistance type fluorescent whitening agent

A fluorescent whitening agent and light-resistant technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor whitening effect and poor light fastness, and achieve enhanced reflectivity, improved light resistance, and improved light resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

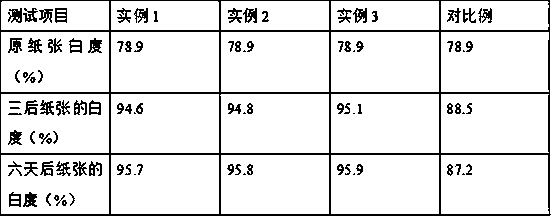

Examples

example 1

[0021] In parts by weight, add 16 parts of diethylenetriamine and 10 parts of distilled water to a four-necked flask equipped with a reflux condenser, thermometer and stirrer, mix and stir for 4 minutes, then add 6 parts of adipic acid and 4 parts by mass fraction 15% sodium hydroxide solution, continue to stir for 10 minutes, after the automatic exothermic end, heat up to 160°C and stir for 6 minutes, until the reaction temperature drops to 120°C, continue to add 5 parts of distilled water to obtain a self-made polyamide solution, Weigh 4g of cyanuric chloride and add it to 16mL of acetone, mix and stir for 8 minutes, add 16g of DSD acid and 3mL of 15% sodium hydroxide solution after stirring, continue to react for 20min, and control the reaction temperature to 3°C. 20% sodium carbonate solution adjusted the pH of the reaction solution to 7, and heated to 8°C, then added 4mL of aniline, then heated to 45°C, added dropwise 5mL of diethanolamine and 12mL of self-made polyamide s...

example 2

[0023] In parts by weight, add 18 parts of diethylenetriamine and 11 parts of distilled water to a four-necked flask equipped with a reflux condenser, thermometer and stirrer, mix and stir for 5 minutes, then add 7 parts of adipic acid and 5 parts by mass fraction 15% sodium hydroxide solution, continue to stir for 11 minutes, after the automatic exothermic end, heat up to 170°C and stir for 7 minutes, until the reaction temperature drops to 130°C, continue to add 6 parts of distilled water to obtain a self-made polyamide solution, Weigh 5g of cyanuric chloride and add it to 18mL of acetone, mix and stir for 9 minutes, add 18g of DSD acid and 4mL of sodium hydroxide solution with a mass fraction of 15% after stirring, continue to react for 25min, and control the reaction temperature to 4°C. 20% sodium carbonate solution adjusted the pH of the reaction solution to 7, and heated to 9°C, then added 5mL of aniline, then heated to 55°C, added dropwise 6mL of diethanolamine and 14mL ...

example 3

[0025]In parts by weight, add 20 parts of diethylenetriamine and 12 parts of distilled water to a four-necked flask equipped with a reflux condenser, a thermometer and a stirrer, mix and stir for 6 minutes, then add 8 parts of adipic acid and 6 parts by mass fraction 15% sodium hydroxide solution, continue to stir for 12 minutes, after the automatic exothermic end, heat up to 180°C and stir for 8 minutes, until the reaction temperature drops to 140°C, continue to add 7 parts of distilled water to obtain a self-made polyamide solution, Weigh 6g of cyanuric chloride and add it to 20mL of acetone, mix and stir for 10min, add 20gDSD acid and 5mL of 15% sodium hydroxide solution after stirring, continue to react for 30min, and control the reaction temperature to 5°C. 20% sodium carbonate solution adjusted the pH of the reaction solution to 9, and heated to 10°C, then added 6mL of aniline, then heated to 65°C, added dropwise 7mL of diethanolamine and 16mL of self-made polyamide solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com