Low-conductivity and high-temperature direct injection disperse dye ink and preparation method thereof

A technology of disperse dyes and low conductivity, which can be used in dyeing, ink, textiles and papermaking, etc. It can solve the problems of insufficient saturation, high conductivity, and poor quality, and achieve high saturation, low conductivity, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

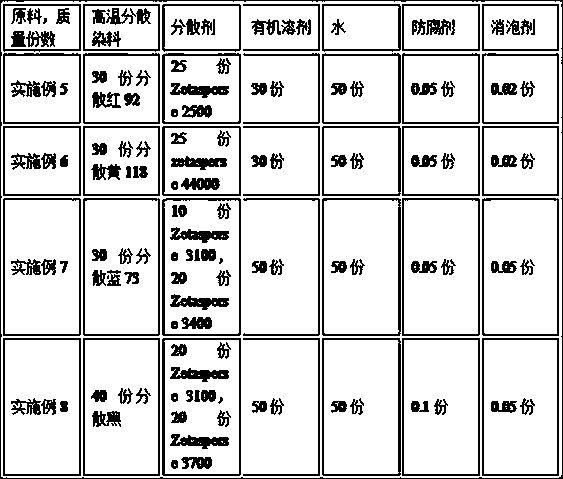

Examples

Embodiment 1

[0065] Example 1: A low-conductivity high-temperature direct-injection disperse dye ink and its preparation method and application

[0066] The low-conductivity high-temperature direct-injection red ink is composed of the following raw materials:

[0067] High temperature disperse red dye 343 20 parts,

[0068] Dispersant 20 parts,

[0069] 30 parts of organic solvent,

[0070] 40 parts of water,

[0071] Preservative 0.05 parts,

[0072] 0.03 parts of defoamer.

[0073] Among them, in the compound dispersant, Zetasperse 3100 occupies 80% by mass percentage, and non-ionic diffusing agent occupies 20%. The non-ionic diffusing agent is the reaction product of an alkylene oxide and an alkylated compound. The alkylene oxide is ethylene oxide, and the alkylated compound is a fatty alcohol with a carbon chain length of 12.

[0074] Preparation of disperse red 343 ink with low conductivity and high temperature direct injection:

[0075] Step 1. In terms of parts by mass, at room temperature, mix 2...

Embodiment 2

[0081] Embodiment 2: A low-conductivity high-temperature direct-injection disperse dye ink and its preparation method and application

[0082] Low-conductivity high-temperature disperse yellow dye ink consists of the following parts by mass of raw materials:

[0083] High temperature disperse yellow dye 114 20 parts,

[0084] Dispersant 24 parts,

[0085] 40 parts of organic solvent,

[0086] 35 parts of water,

[0087] Preservative 0.06 parts,

[0088] Defoamer: 0.02 parts.

[0089] Among them, in the compound dispersant, Zetasperse 3600 occupies 90% by mass percentage, and non-ionic diffusing agent accounts for 10%. The non-ionic diffusing agent is the reaction product of an alkylene oxide and a compound that can be alkylated. The alkylene oxide is propylene oxide, and the alkylated compound is a fatty alcohol with a carbon chain length of 12.

[0090] Preparation of disperse yellow 114 ink with low conductivity and high temperature direct injection:

[0091] Step 1. In terms of parts by ...

Embodiment 3

[0097] Embodiment 3: A low-conductivity high-temperature direct-injection disperse dye ink and its preparation method and application

[0098] Low-conductivity high-temperature direct-injection disperse blue dye ink consists of the following raw materials:

[0099] High temperature disperse blue dye 60 20 parts,

[0100] 35 parts of dispersant,

[0101] 50 parts of organic solvent,

[0102] 60 parts of water,

[0103] Preservative 0.05 parts,

[0104] 0.04 parts of defoamer.

[0105] Among them, in the compound dispersant, in terms of mass percentage, Zetasperse 3800 accounts for 95%, and non-ionic diffusing agent accounts for 5%. The non-ionic diffusing agent is the reaction product of alkylene oxide and alkylated compound. The alkylene oxide is propylene oxide, and the alkylated compound is a fatty alcohol with a carbon chain length of 12.

[0106] Preparation of disperse blue 60 ink with low conductivity and high temperature direct injection:

[0107] Step 1. In terms of parts by mass, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com