Noble metal catalyst for catalyzing wet oxidation industrial wastewater, and preparation method and application thereof

A precious metal catalyst, a technology for catalytic wet oxidation, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as unfavorable industrial production and complex process routes, Achieve the effect of reducing temperature and pressure, simple preparation process route and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

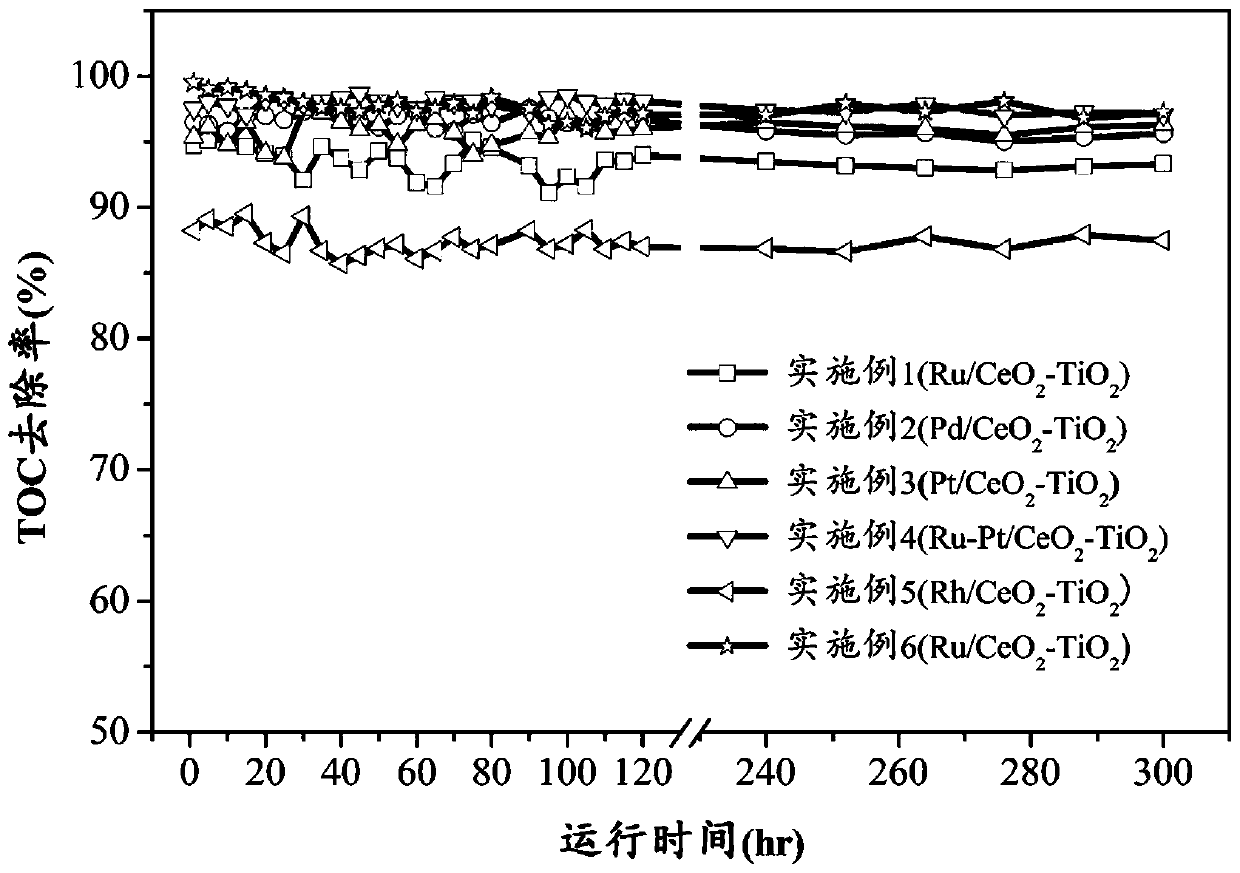

[0050] Simulated wastewater application test: Prepare triethylamine simulated wastewater with TOC=5300 mg / L, adjust wastewater pH=5~6 with acid, take a certain amount of supported precious metal catalyst in fixed bed reaction tube, and inject air until the total pressure is 5 MPa, heat and maintain the temperature in the reaction tube at 220°C, and the reaction space velocity is 1 h -1 , during the reaction process, waste water and air continue to enter the reaction system in a certain proportion, and the specific results of the treatment of the catalyst described in Examples 1 to 6 are shown in figure 1 .

Embodiment 8

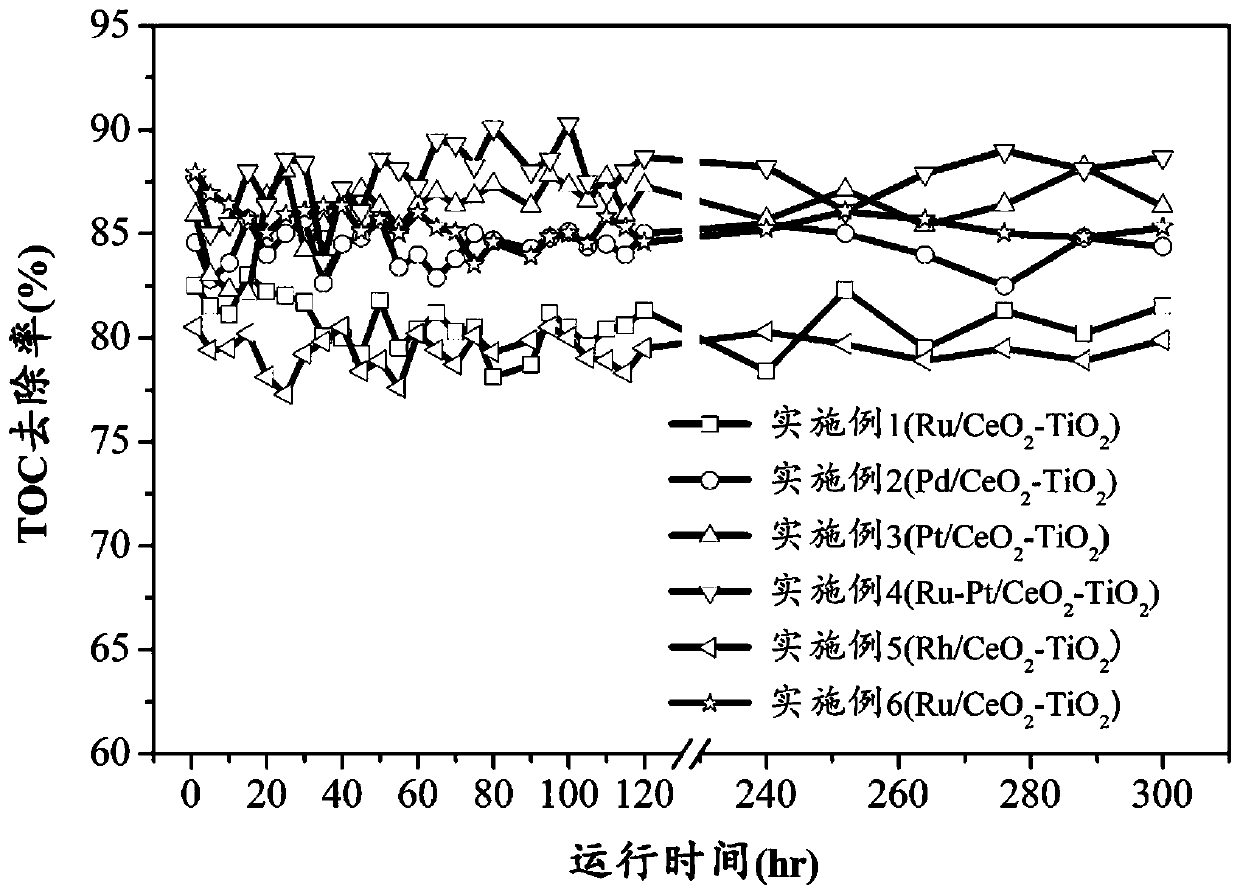

[0052] Actual industrial wastewater application test: Take a certain dye company’s industrial production wastewater, COD=35800 mg / L, TOC=14600mg / L, take a certain amount of supported noble metal catalyst in the fixed bed reaction tube, and feed air until the total pressure is 5 MPa , heat and maintain the temperature in the reaction tube at 220 °C, and the reaction space velocity is 1 h -1 , during the reaction process, waste water and air continue to enter the reaction system in a certain proportion, and the specific results of the catalyst described in Examples 1 to 6 are shown in figure 2 .

Embodiment 9

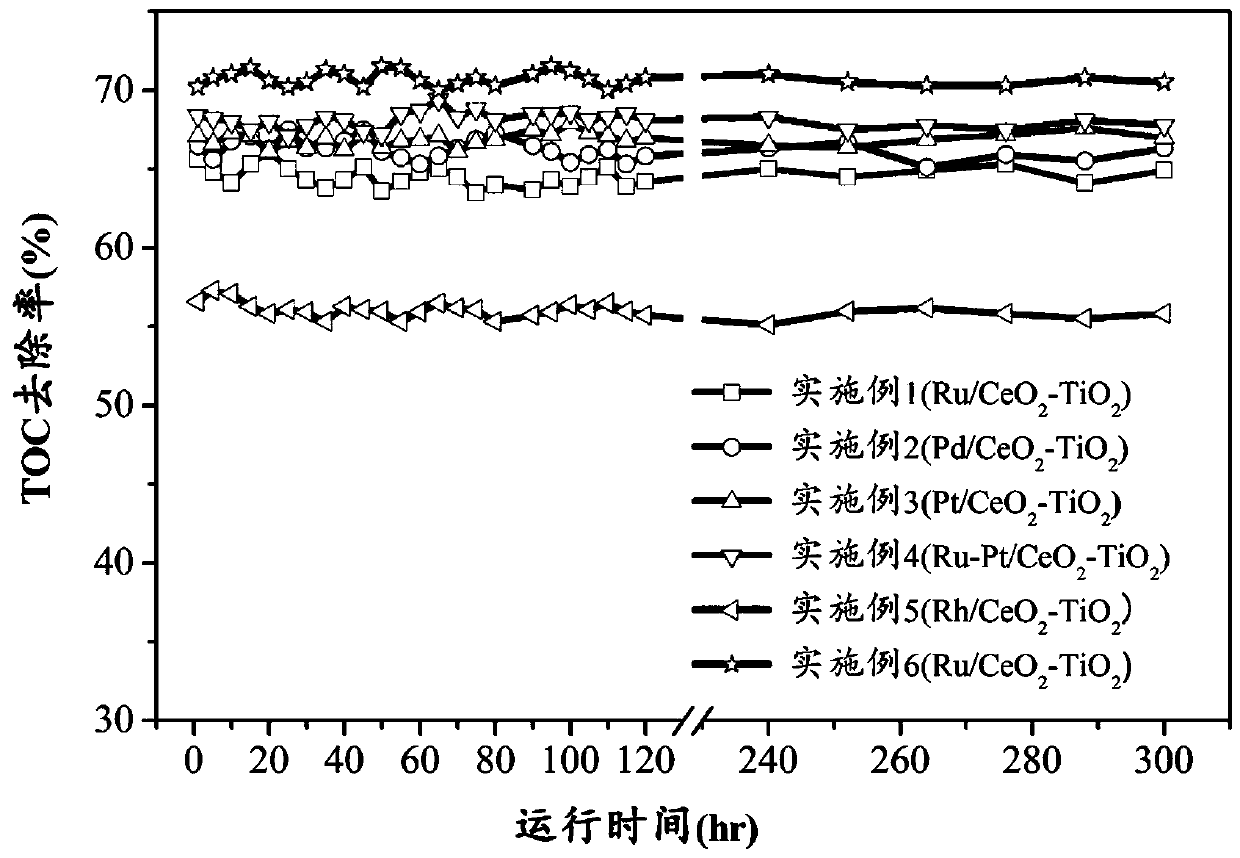

[0054] Actual industrial wastewater application test: Take the industrial production wastewater of a dyestuff company, COD=27600 mg / L, TOC=10500mg / L, take a certain amount of supported precious metal catalyst in the fixed bed reaction tube, and feed air until the total pressure is 3 MPa , heating and maintaining the temperature in the reaction tube at 180 °C, and the reaction space velocity at 2 h -1 , during the reaction process, waste water and air continue to enter the reaction system in a certain proportion, and the specific results of the treatment of the catalyst described in Examples 1 to 6 are shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com