Compound photocatalyst Ag2CO3/g-C3N4 as well as preparation method and application thereof

A catalyst and composite light technology, applied in the field of photocatalysis, can solve the problems of low catalytic efficiency, low quantum efficiency, high photogenerated electron-hole recombination rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

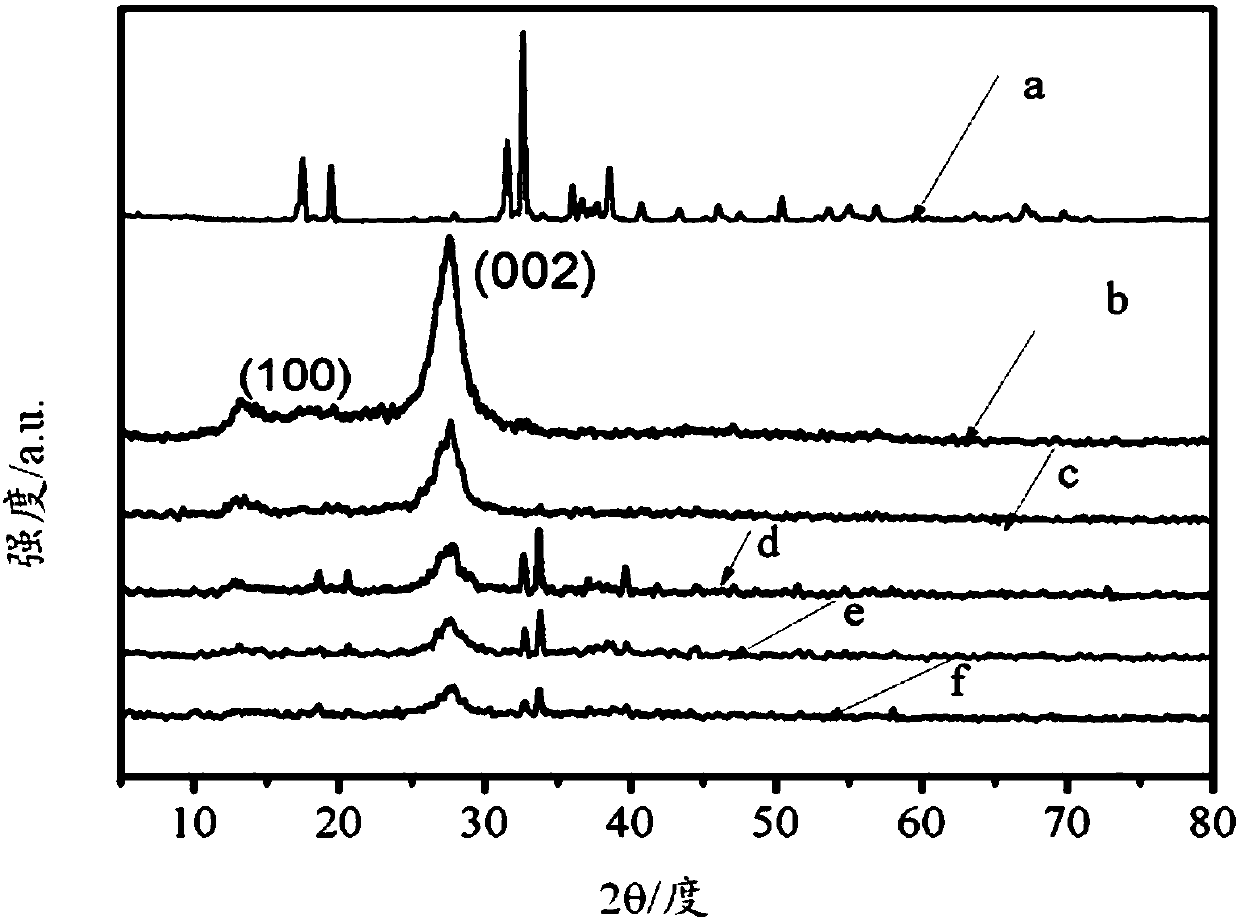

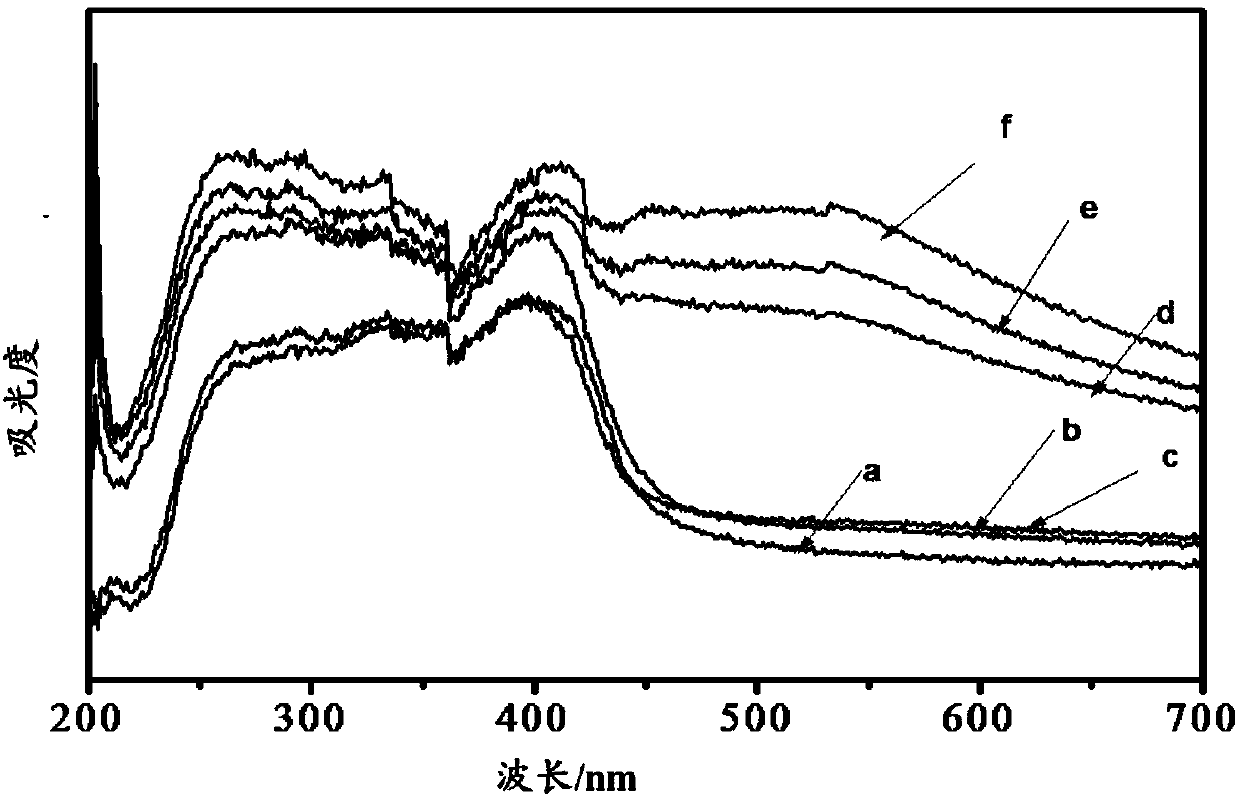

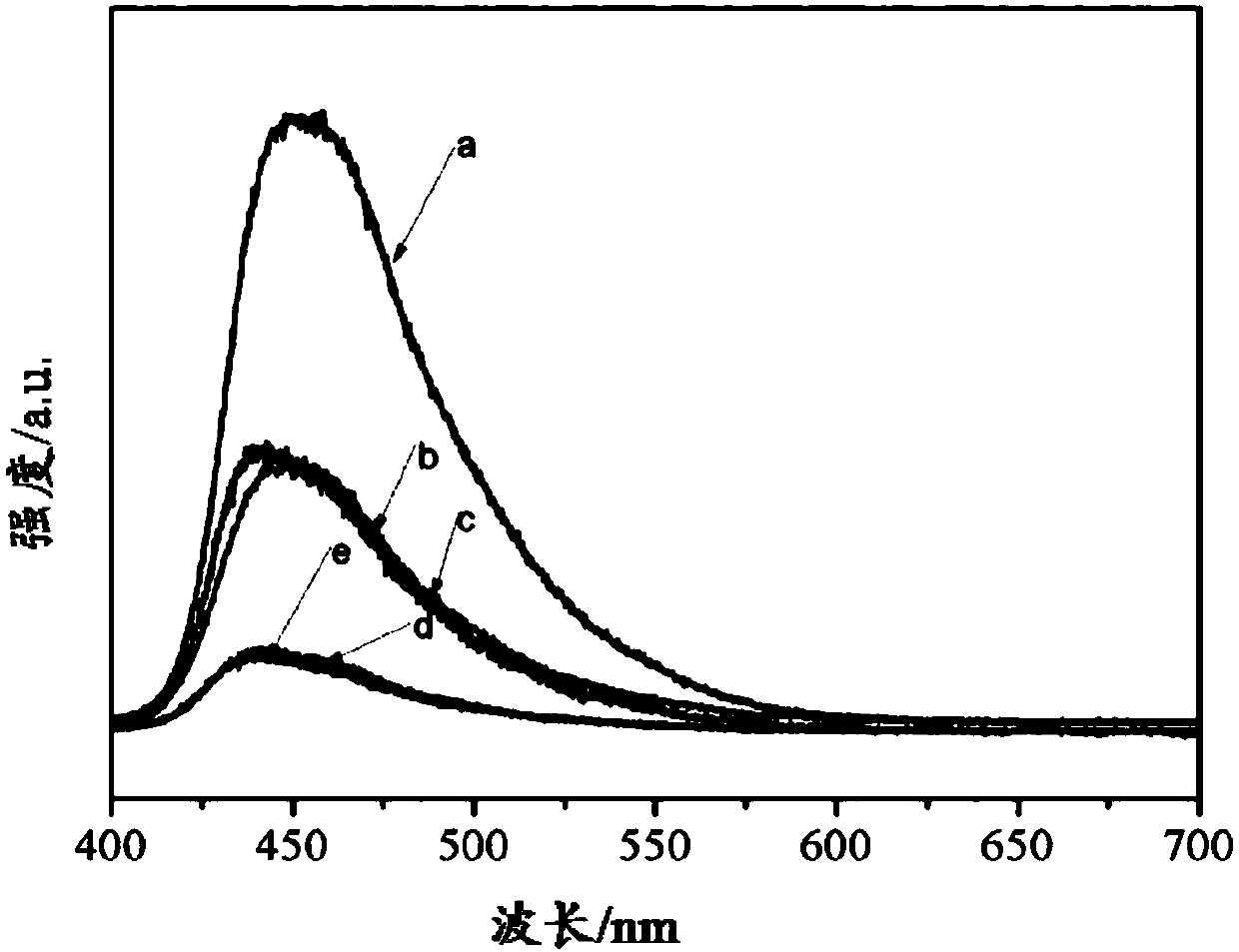

[0018] A composite photocatalyst Ag 2 CO 3 / g -C 3 N 4 The preparation method, this method comprises the following steps:

[0019] Step (1), calcining nitrogen-containing organic matter, cooling to obtain product I, which is g-C 3 N 4 .

[0020] Since no natural g-C has been found so far 3 N 4 Crystal structure, so the application of his research requires laboratory synthesis. The commonly used synthetic methods are: high temperature and high pressure method, deposition method, solvothermal method and thermal polymerization method. Since the thermal polymerization method can be conveniently adjusted by adding other substances or changing the reaction conditions, g-C 3 N 4 crystal structure, thereby enhancing the g-C 3 N 4 The photocatalytic performance is currently commonly used for thermal polymerization and calcined synthesis.

[0021] In the present invention, the calcination is carried out at 300-800°C, preferably at different temperatures in stages, more pref...

Embodiment 1

[0058] Accurately weigh 5.0000g of melamine with an electronic balance, put the weighed medicine in a crucible, then place the crucible in a muffle furnace, set the temperature at 500°C for two hours, and continue to calcine at 520°C for two hours. Take out the medicine and cool it to room temperature, and after grinding, you will get bright yellow g-C 3 N 4 sample.

[0059] Accurately weigh 0.3036g of the prepared g-C with an electronic balance 3 N 4 Disperse in 8ml of deionized water, then sonicate for 30min. The 2ml concentration is 0.11mol L -1 The silver nitrate solution was added to the above-mentioned sonicated solution, and stirred for 30 minutes in the dark.

[0060] Continue to add 5ml 0.05mol·L -1 NaHCO 3 The solution was in the above suspension, and stirred for 2 h in the dark. The precipitate was first collected by centrifugation, then washed with deionized water and absolute ethanol, and dried in a drying oven at 60° C. for 4 h. Cool to room temperature,...

Embodiment 2

[0062] Accurately weigh 5.0000g of melamine with an electronic balance, put the weighed medicine in a crucible, then place the crucible in a muffle furnace, set the temperature at 500°C for two hours, and continue to calcine at 520°C for two hours. Take out the medicine and cool it to room temperature, and after grinding, you will get bright yellow g-C 3 N 4 sample.

[0063] Accurately weigh 0.1518g of the prepared g-C with an electronic balance 3 N 4 Disperse in 8ml of deionized water, then sonicate for 30min. The 2ml concentration is 0.11mol L -1 The silver nitrate solution was added to the above-mentioned sonicated solution, and stirred for 30 minutes in the dark.

[0064] Continue to add 5ml 0.05mol·L -1 NaHCO 3 The solution was in the above suspension, and stirred for 2 h in the dark. The precipitate was first collected by centrifugation, then washed with deionized water and absolute ethanol, and dried in a drying oven at 60° C. for 4 h. Cool to room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com