Plasticizer-free low-hardness high-fracture-elongation-rate polyurethane elastomer material composition and preparation method thereof

A technology of polyurethane elastomer and elongation at break, which is applied to the composition and preparation field of two-component room temperature-curing polyurethane elastomer, can solve the problems of non-resistance to solvents, inability to meet the elongation at break and the like, and achieves The effect of high elongation at break, safety and environmental protection mechanical properties and process performance, and great economic significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

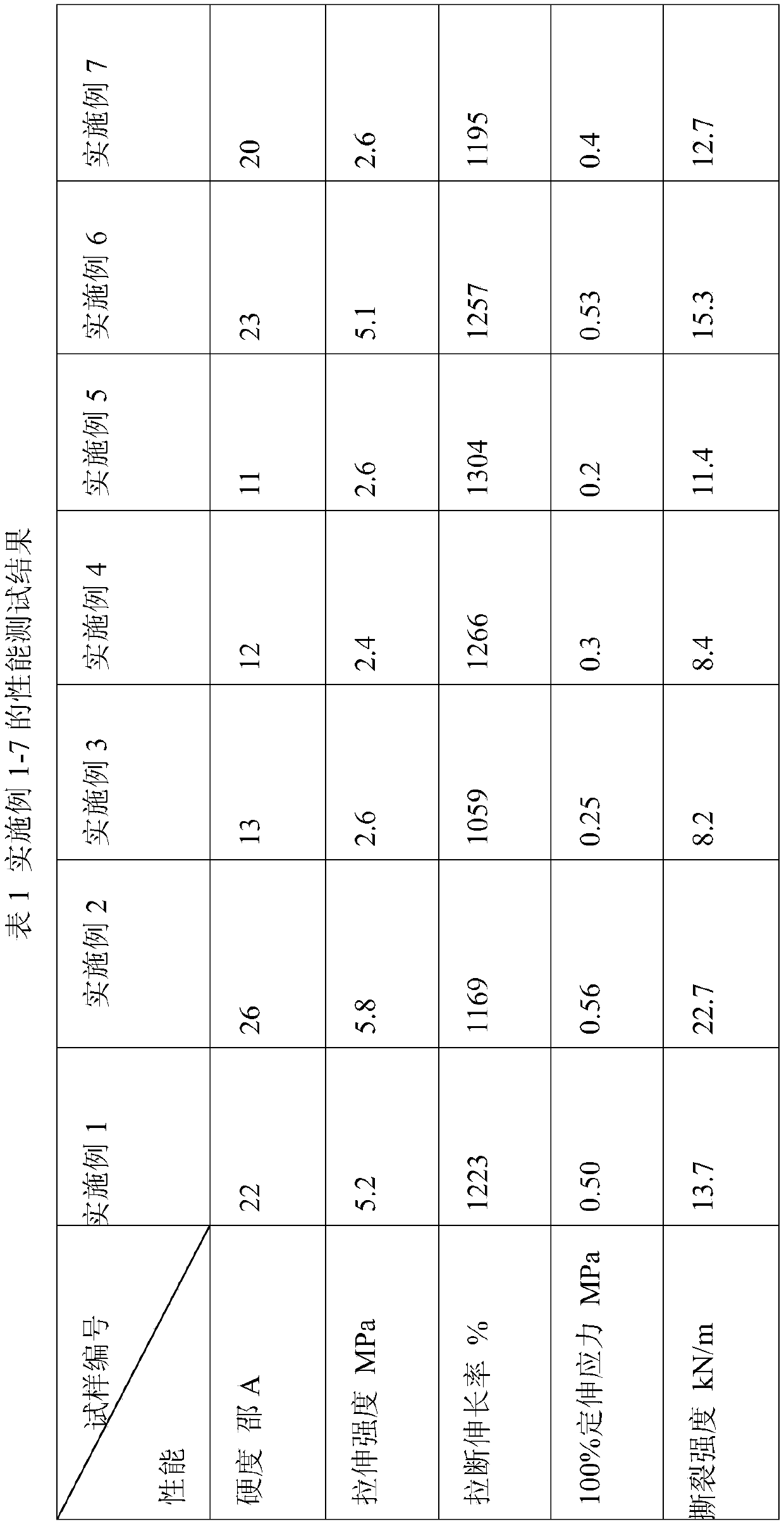

Examples

Embodiment 1

[0048] A component: polyol component: obtained according to the following preparation method: in parts by weight, polypropylene oxide ether polyol (CHE-824) 50 with a molecular weight of 7000, and a polypropylene oxide-ethylene oxide with a molecular weight of 8000 Copolyether polyol (CHE-280) 50, chain extender 1, 4-BDO 3.48, ultraviolet absorber UV-531 0.5, catalyst mercuric isooctanoate 0.05, catalyst A330.05, antioxidant 1010 0.5, defoamer BYK -A550 0.6, mix and stir at 100±10°C, vacuum degree -0.1MPa, and vacuumize.

[0049] Component B: Isocyanate component: Obtained according to the following preparation method: In weight percentage, 82.4% of polypropylene oxide-ethylene oxide copolyether polyol (CHE-280) with 2 functionalities and a molecular weight of 8000, diphenyl Methane diisocyanate (MDI-100) 16.7%, carbodiimide modified diphenylmethane diisocyanate (MDI-100LL) 0.9%, react at 80°C for 2 to 3 hours to obtain a preform with an isocyanate content of 5%. Polymer.

...

Embodiment 2

[0052] A component: polyol component: obtained according to the following preparation method: in parts by weight, polypropylene oxide ether polyol (CHE-824) 60 with a molecular weight of 7000, and a polypropylene oxide-ethylene oxide with a molecular weight of 8000 Copolyether polyol (CHE-280) 40, chain extender EG 3.52, ultraviolet absorber UV-531 0.5, catalyst mercuric isooctanoate 0.05, catalyst A33 0.05, antioxidant 1010 0.5, defoamer BYK-066N 0.6, in 100±10°C, mixing, stirring and vacuuming at a vacuum degree of -0.1MPa.

[0053] Component B: Isocyanate component: Obtained according to the following preparation method: In weight percentage, 82.4% of polypropylene oxide-ethylene oxide copolyether polyol (CHE-280) with 2 functionalities and a molecular weight of 8000, diphenyl Methane diisocyanate (MDI-100) 16.7%, carbodiimide modified diphenylmethane diisocyanate (MDI-100LL) 0.9%, react at 80°C for 2 to 3 hours to obtain a preform with an isocyanate content of 5%. Polymer...

Embodiment 3

[0056] A component: polyol component: obtained according to the following preparation method: in parts by weight, polypropylene oxide ether polyol (CHE-824) 60 with a molecular weight of 7000, and a polypropylene oxide-ethylene oxide with a molecular weight of 8000 Copolyether polyol (CHE-280) 40, chain extender EG 3.28, ultraviolet absorber UV-531 0.5, catalyst mercuric isooctanoate 0.05, catalyst A33 0.05, antioxidant 1010 0.5, at 100±10°C, vacuum degree- Stirring and vacuuming at 0.1MPa.

[0057] Component B: Isocyanate component: Obtained according to the following preparation method: In weight percentage, 82.4% of polypropylene oxide-ethylene oxide copolyether polyol (CHE-280) with 2 functionalities and a molecular weight of 8000, diphenyl Methane diisocyanate (MDI-100) 16.7%, carbodiimide modified diphenylmethane diisocyanate (MDI-100LL) 0.9%, react at 80°C for 2 to 3 hours to obtain a preform with an isocyanate content of 5%. Polymer.

[0058] The isocyanate component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com