Preparation method of hydrophobic white carbon black

A white carbon black and hydrophobicity technology, which is applied in the field of preparation of hydrophobic white carbon black, can solve the problems of cumbersome preparation methods and reduced processing performance of white carbon black, and achieve long reaction time, good technical economy, and reinforcement The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

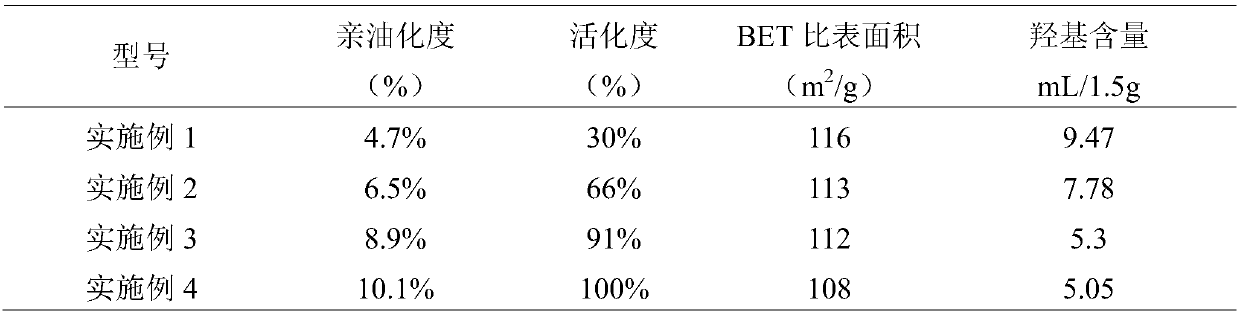

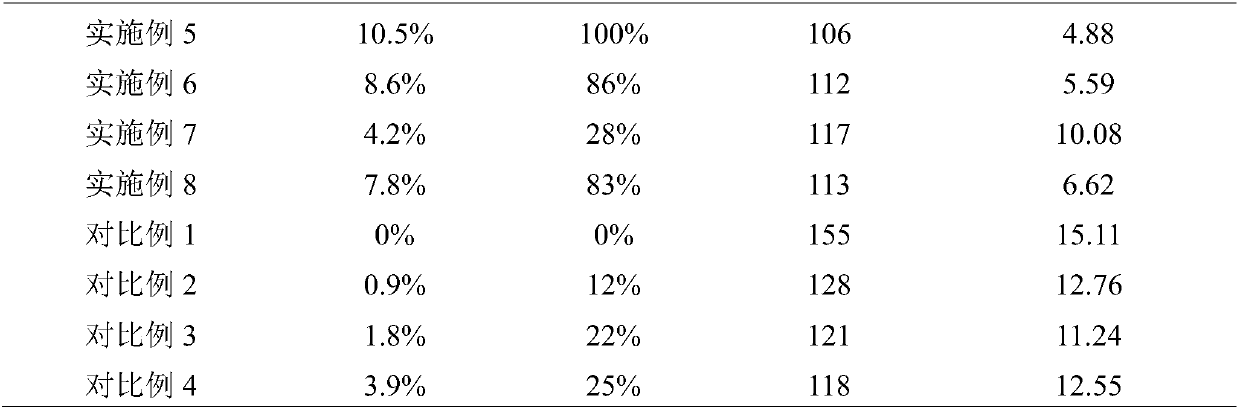

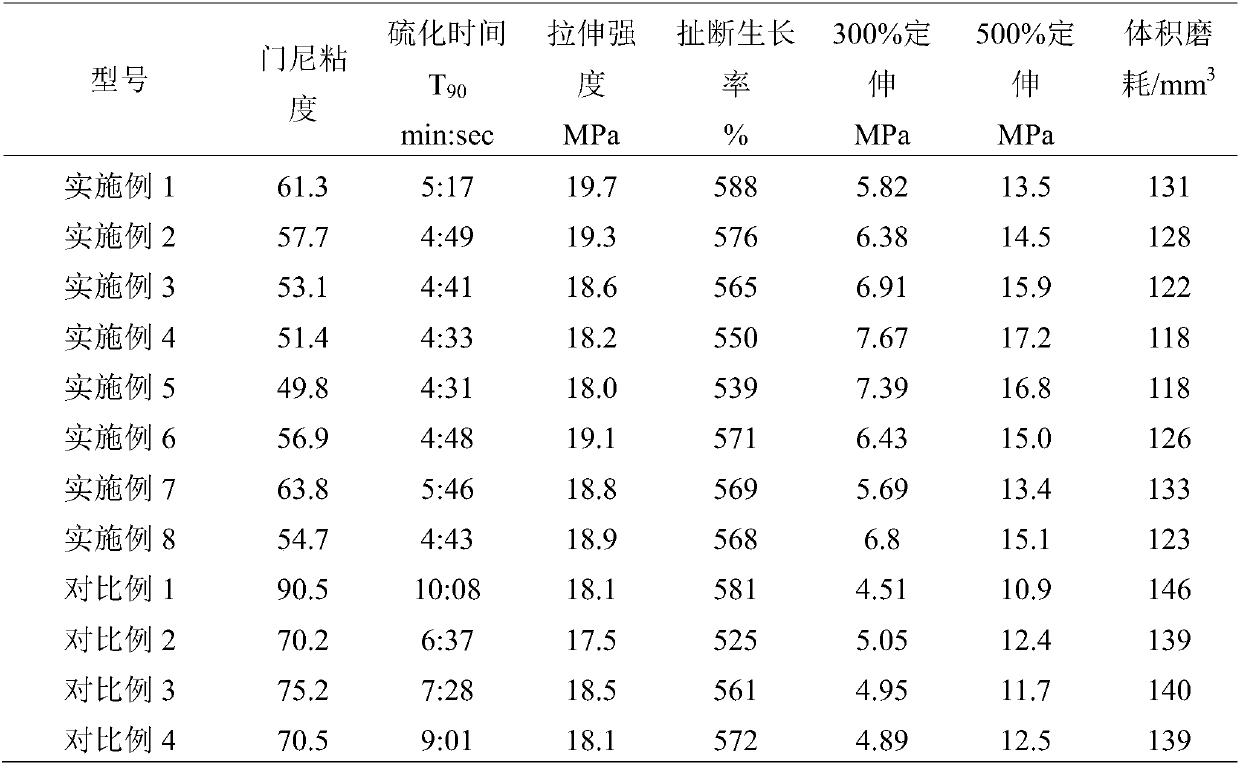

Examples

Embodiment 1

[0050] The present embodiment provides a kind of preparation method of hydrophobic white carbon black, and its specific method is:

[0051] (1) Add silane coupling agent A151, absolute ethanol, n-heptane, dichloromethane and distilled water into the beaker according to the volume ratio of 1:2:1:0.1:1, and place the beaker on a magnetic stirrer Stir at 25° C. for 30 minutes to carry out the hydrolysis reaction to obtain the hydrolyzate of the silane coupling agent A151.

[0052] (2) silane coupling agent A151 hydrolyzate is mixed evenly with 200g white carbon black (the mass of silane coupling agent A151 and the white carbon black mass ratio are 9.5:100, m 硅烷偶联剂A151 =19g), the white carbon black-silane coupling agent mixture is placed in an oven, ventilated and dried at 35°C for 2h to remove the ethanol therein, and then the modification reaction is carried out at a temperature of 50°C, and the modification reaction time is 20min, A hydrophobic precipitated silica is obtained....

Embodiment 2

[0055] The present embodiment provides a kind of preparation method of hydrophobic white carbon black, and its specific method is:

[0056] (1) Add silane coupling agent A151, absolute ethanol, n-heptane, dichloromethane and distilled water into the beaker according to the volume ratio of 1:2:1:0.5:1, and place the beaker on a magnetic stirrer Stir at 35° C. for 30 minutes to carry out the hydrolysis reaction to obtain the hydrolyzate of the silane coupling agent A151.

[0057] (2) silane coupling agent A151 hydrolyzate is mixed evenly with 200g white carbon black (the mass of silane coupling agent A151 and the white carbon black mass ratio are 12.5:100, m 硅烷偶联剂A151 =25g), the white carbon black-silane coupling agent mixture is placed in an oven, ventilated and dried at 35°C for 2h to remove the ethanol therein, and then the modification reaction is carried out at a temperature of 85°C, and the modification reaction time is 60min, A hydrophobic precipitated silica is obtained...

Embodiment 3

[0060] The present embodiment provides a kind of preparation method of hydrophobic white carbon black, and its specific method is:

[0061] (1) Add silane coupling agent A151, absolute ethanol, n-heptane, dichloromethane and distilled water into the beaker according to the volume ratio of 1:2:1:0.2:1, and place the beaker on a magnetic stirrer Stir at 45° C. for 30 minutes to carry out the hydrolysis reaction to obtain the hydrolyzate of the silane coupling agent A151.

[0062] (2) silane coupling agent A151 hydrolyzate is mixed evenly with 200g white carbon black (the mass of silane coupling agent A151 and the mass ratio of white carbon black are 15.5:100, m 硅烷偶联剂A151 =31g), the white carbon black-silane coupling agent mixture is placed in an oven, ventilated and dried at 35°C for 2h to remove the ethanol therein, and then the modification reaction is carried out at a temperature of 110°C, and the modification reaction time is 90min, A hydrophobic precipitated silica is obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com