Parabramis pekinensis feed for improving fish meat quality

A technology for improving meat quality and bream, applied in the field of bream feed, can solve problems affecting the quality of bream, not considering the stability and balance of the digestive system of bream, and affecting the healthy growth of bream, so as to help digestion and absorption , Eliminate fishy smell and improve taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

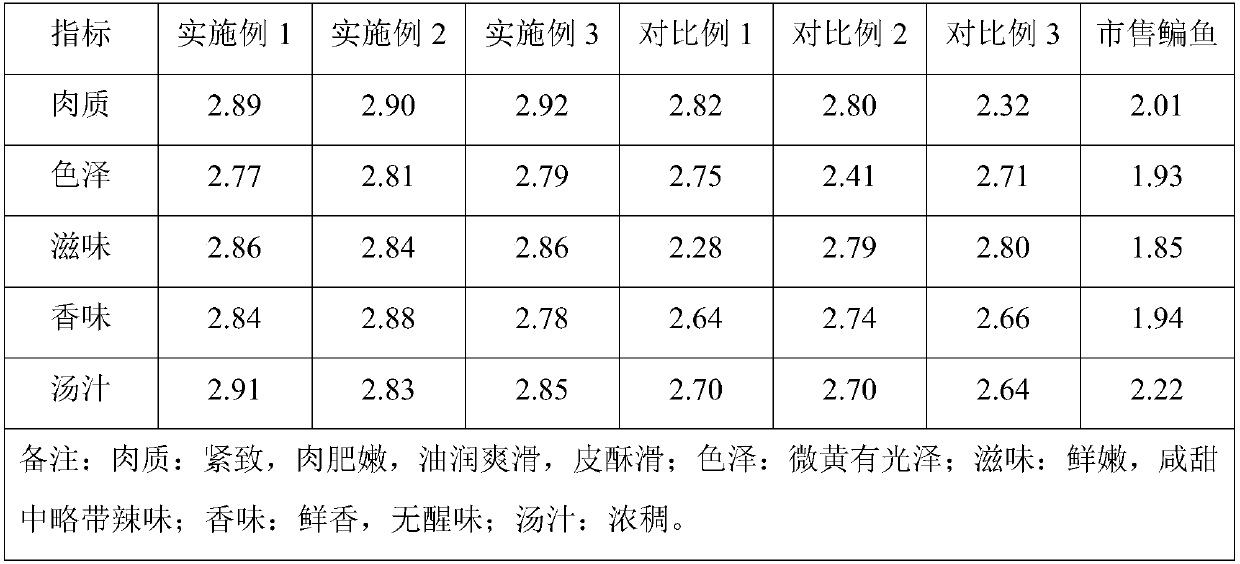

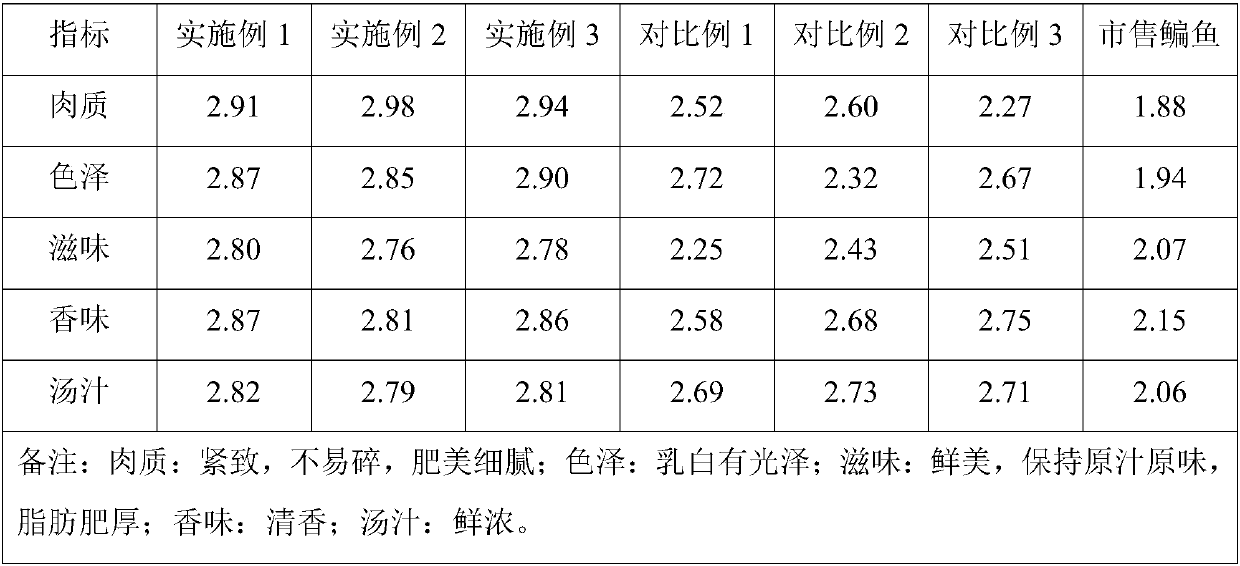

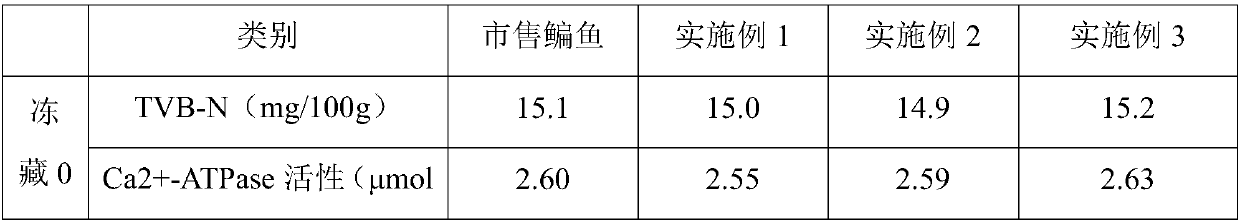

Examples

Embodiment 1

[0030] A bream feed for improving meat quality, comprising the following components in parts by weight: 55 parts of corn flour, 10 parts of soybean dregs, 8 parts of black bean flour, 8 parts of secondary flour, 15 parts of nutritional enhancer, and 3 parts of food attractant , 3 parts of conditioner, and 3 parts of table salt;

[0031] Wherein, the nutritional enhancer comprises the following raw materials by weight: 8 parts of water earthworm powder, 3 parts of sheep liver powder, 3 parts of shrimp shell powder, 3 parts of kelp powder, 3 parts of chestnut kernel, 1 part of dried longan powder, and silver 1 part guayule;

[0032] The food attractant is made from the following raw materials in parts by weight: 0.8 parts of Gynostemma pentaphyllum, 0.8 parts of Ashen leaves, 0.8 parts of dry yeast, 0.8 parts of celery powder, 0.8 parts of ebony plums, 0.5 parts of Daidaihua, 0.5 parts of Danzhu leaves, and 0.5 parts of Ji Nei Jin 0.5 parts, 10 parts of corn oil, 10 parts of sw...

Embodiment 2

[0045] A bream feed for improving meat quality, comprising the following components in parts by weight: 65 parts of corn flour, 18 parts of soybean dregs, 10 parts of black bean flour, 10 parts of secondary flour, 25 parts of nutritional enhancer, and 5 parts of food attractant , 5 parts of conditioner, and 5 parts of table salt;

[0046] Wherein, the nutritional enhancer comprises the following raw materials by weight: 10 parts of water earthworm powder, 5 parts of sheep liver powder, 5 parts of shrimp shell powder, 5 parts of kelp powder, 5 parts of chestnut kernel, 3 parts of dry longan powder, and silver 3 parts guayule;

[0047] The food attractant is made from the following raw materials in parts by weight: 1 part of Gynostemma pentaphyllum, 1 part of Ashen leaf, 1 part of dry yeast, 1 part of celery powder, 1 part of ebony plum, 0.8 part of Daidaihua, 0.8 part of light bamboo leaf, and 0.8 part of Ji Nei Jin 0.8 parts, 20 parts of corn oil, 20 parts of sweet potato flo...

Embodiment 3

[0059] A bream feed for improving meat quality, comprising the following components in parts by weight: 60 parts of corn flour, 14 parts of soybean dregs, 9 parts of black bean flour, 9 parts of secondary flour, 20 parts of nutritional enhancer, and 4 parts of food attractant , 4 parts of conditioner, and 4 parts of table salt;

[0060] Wherein, the nutritional enhancer comprises the following raw materials in parts by weight: 9 parts of water earthworm powder, 4 parts of sheep liver powder, 4 parts of shrimp shell powder, 4 parts of kelp powder, 4 parts of chestnut kernel, 2 parts of dry longan powder, and silver 2 parts guayule;

[0061] The food attractant is made of the following raw materials in parts by weight: 0.9 parts of Gynostemma pentaphyllum, 0.9 parts of Ashen leaves, 0.9 parts of dry yeast, 0.9 parts of celery powder, 0.9 parts of ebony plums, 0.6 parts of Daidaihua, 0.7 parts of Danzhu leaves, and 0.9 parts of Ji Nei Jin 0.6 parts, 15 parts of corn oil, 16 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com