Heavy metal contaminated soil improving coated fertilizer and preparation method thereof

A technology that pollutes soil and heavy metals. It is applied to layered/coated fertilizers, organic fertilizers, and excreted fertilizers. It can solve the problems of low utilization rate of chemical fertilizers in the current season, delay the release cycle of fertilizers, and improve impact resistance and surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

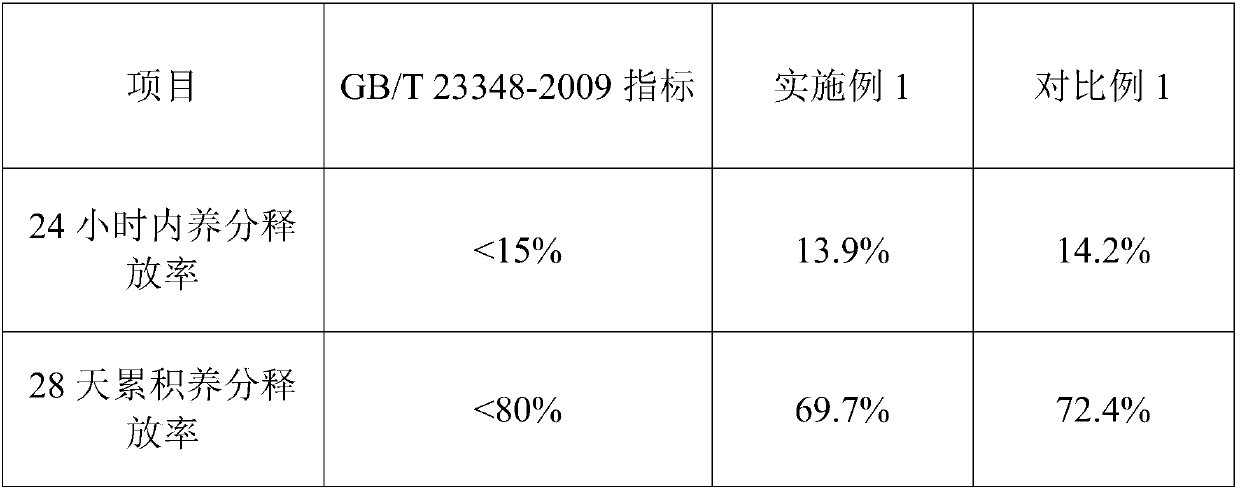

Embodiment 1

[0025] Select soybean straw and crush it to a length less than 1 cm, put it in a pyrolysis furnace, control the temperature at 500°C, and pyrolyze it for 1 hour under anaerobic conditions, take out the prepared biochar after cooling, and crush it to a particle size of less than 200 head. The fresh vermicompost is air-dried and crushed until the particle size is less than 200 mesh. Screen 100kg of fertilizer granules with a diameter of 2-3mm, add them to the drum fluidized bed, and preheat them at 70°C. Add 7 kg of ammonium magnesium phosphate and 13 kg of palm oil into the reaction kettle and stir for 2 hours at 100° C. to obtain a homogenized coating. Spray the coated homogenate evenly onto the preheated fertilizer surface. Mix 9kg of biochar powder and 16kg of vermicompost powder evenly, wrap them on the surface of the sprayed and homogenized fertilizer, cool, and dry to obtain a coated fertilizer S1 that can improve heavy metal-polluted soil.

Embodiment 2

[0027] Select soybean straw and crush it to a length less than 1 cm, put it in a pyrolysis furnace, control the temperature at 1000°C, and pyrolyze it for 1 hour under anaerobic conditions, take out the prepared biochar after cooling, and crush it to a particle size of less than 200 head. The fresh vermicompost is air-dried and crushed until the particle size is less than 200 mesh. Screen 100kg of fertilizer granules with a diameter of 3-4mm, add them to the drum fluidized bed, and preheat them at 85°C. Add 6 kg of ammonium magnesium phosphate and 17 kg of palm oil into the reaction kettle and stir for 2 hours at 120° C. to obtain a coated homogenate. Spray the coated homogenate evenly onto the preheated fertilizer surface. Mix 12kg of biochar powder and 15kg of vermicompost powder evenly and wrap them on the surface of the fertilizer that has been sprayed with homogenate, cool and dry to obtain a coated fertilizer S2 that can improve heavy metal-contaminated soil.

Embodiment 3

[0029] Select soybean stalks to be crushed to a length of less than 1 cm, put them in a pyrolysis furnace, control the temperature at 1000 ° C, and pyrolyze them for 0.8 h under anaerobic conditions, take out the prepared biochar after cooling, and crush them to a particle size smaller than 200 mesh. The fresh vermicompost is air-dried and crushed until the particle size is less than 200 mesh. Screen 100kg of fertilizer granules with a diameter of 3-4mm, add them to the drum fluidized bed, and preheat them at 85°C. Add 8 kg of magnesium ammonium phosphate and 17 kg of palm oil into the reaction kettle and stir at 150° C. for 2 hours to obtain a homogenized coating. Spray the coated homogenate evenly onto the preheated fertilizer surface. Mix 10kg of biochar powder and 20kg of vermicompost powder evenly, wrap them on the surface of the fertilizer that has been sprayed with homogenate, cool, and dry to obtain a coated fertilizer S3 that can improve heavy metal-contaminated soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com