Light source system and projection equipment

A light source system and light source technology, applied in the field of optics, can solve problems such as low light utilization efficiency, achieve the effect of improving light utilization rate and avoiding light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

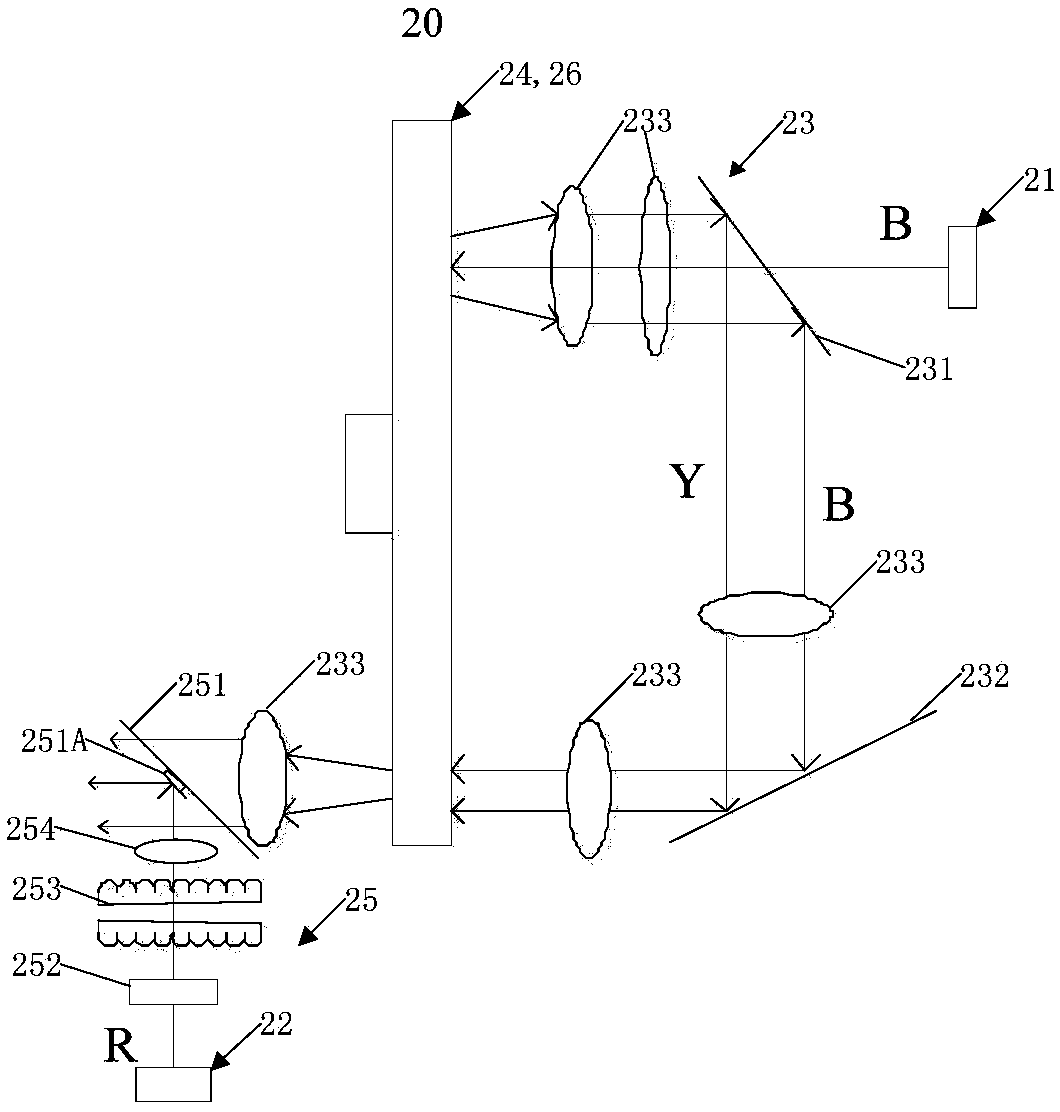

[0057] This embodiment provides a light source system 20, such as figure 2 As shown, the light source system 20 includes two light sources, respectively an excitation light source 21 and a first supplementary light source 22 , and also includes a first light guide assembly 23 , a wavelength conversion device 24 , and a second light guide assembly 25 . In this embodiment, the wavelength conversion device is a reflective color wheel 24 (such as a wavelength conversion layer directly coated on a reflective substrate) as an example, of course, the wavelength conversion device may also be a transmission wavelength conversion device (such as including a transparent substrate and a wavelength conversion material doped inside the transparent substrate). The wavelength conversion material includes but not limited to phosphor powder, quantum dot material and the like. The wavelength conversion layer is a layer of wavelength conversion material or a diaphragm formed by sintering the wa...

Embodiment 2

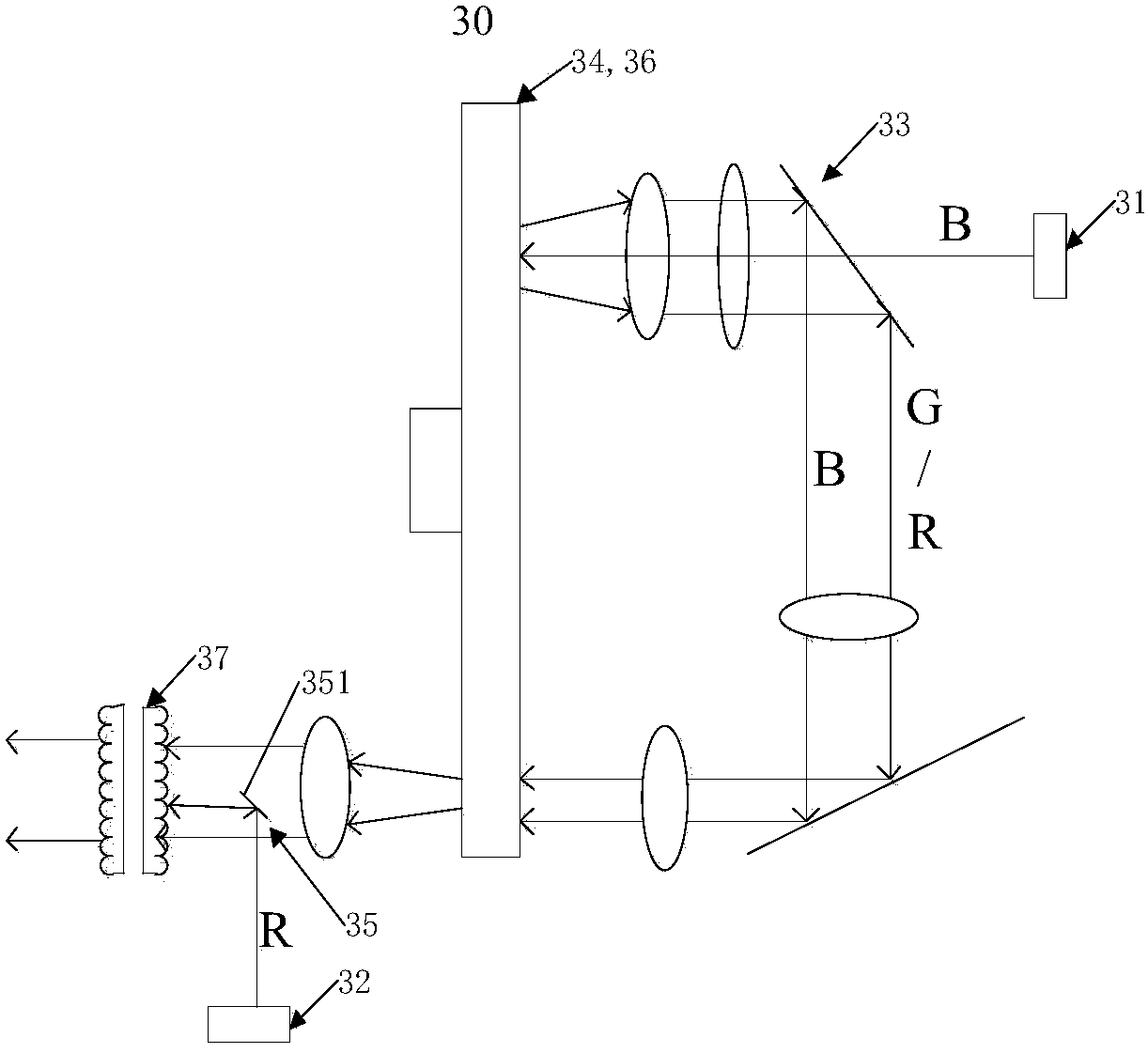

[0065] This embodiment provides another light source system 30, such as image 3 As shown, the light source system 30 and figure 2 The main difference of the light source system 20 shown is the arrangement of the second light guide assembly 35. Specifically, compared with Embodiment 1, the second light guide assembly 35 is not located between the selective optical component 351 and the first supplementary light source 32. A scattering component and a light homogenizing component are arranged between them, and further, a light homogenizing device 37 is arranged on the same exit channel from which the first supplementary light and the received light exit. The above-mentioned light source system 30 provided in this embodiment will be described below with a specific example, assuming that the excitation light emitted by the excitation light source 31 is blue excitation light B, and the first supplementary light emitted by the first supplementary light source 32 is red light R, T...

Embodiment 3

[0067] This embodiment provides another light source system 40, such as Figure 6 As shown, the light source system 40 and image 3 The main difference of the light source system 30 shown is that a first supplementary light source 42' is added, specifically, the first supplementary light source 42 and the first supplementary light source 42' are arranged on the same side of the selective optical component 451, and the first supplementary light source 42' The light source 42' and the first supplementary light source 42 are located on both sides of the light-splitting element 455 included in the second light guide assembly 45. One of them is transmitted and reflected by the other and exits to the selective optical component 451 from the same optical path. Therefore, even if two first supplementary light sources are provided, the area of the incident area corresponding to all the first supplementary light sources of the selective optical component 451 does not need to be Corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com