Fine particulate matter purification system and method suitable for low-temperature environment

A technology of fine particulate matter and low temperature environment, applied in the field of air pollution control, can solve the problems of low condensation rate, reduced collision probability of fine particulate matter, difficult to apply to low temperature environment, etc., so as to improve the removal effect and avoid the effect of freezing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

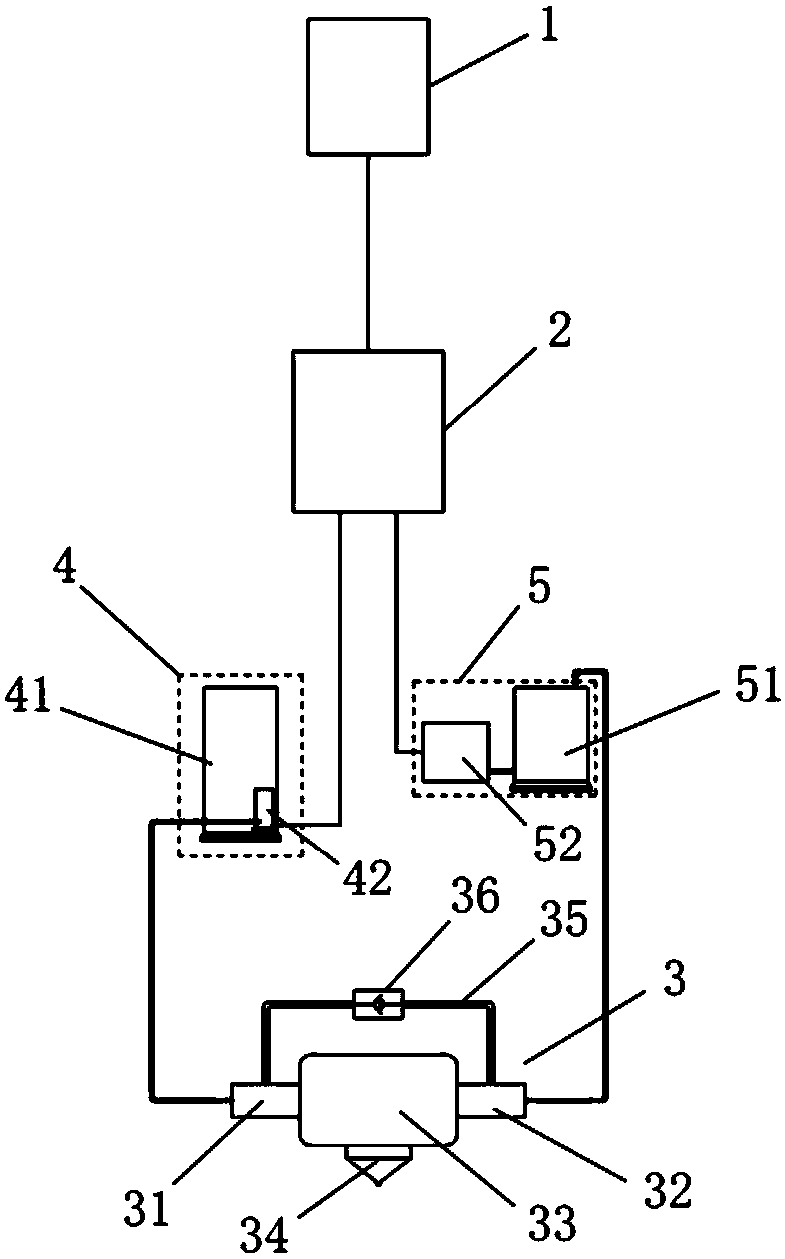

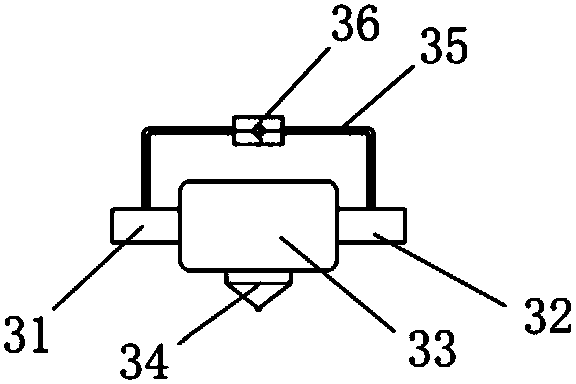

[0049] A fine particle purification system of the present invention, the fine particle purification system is suitable for the purification of fine particles in various environments, especially suitable for purifying fine particles in the air in low temperature environments (such as -25°C to 0°C) deal with. Its structure diagram is as follows: figure 1 and figure 2 shown by figure 1 and figure 2 It can be seen that it mainly includes a fine particle detector 1, a processor 2, a gas-liquid two-phase flow cloud nozzle 3, a water supply device 4 and an air supply device 5. Wherein, the output end of the fine particle detector 1 is electrically connected with the input end of the processor 2, and is used to collect the fine particle concentration information in the environment, generate an electric signal related to the fine particle concentration, and transmit the electric signal to the processing device 2; the water outlet end of the water supply device 4 and the gas outle...

Embodiment 2

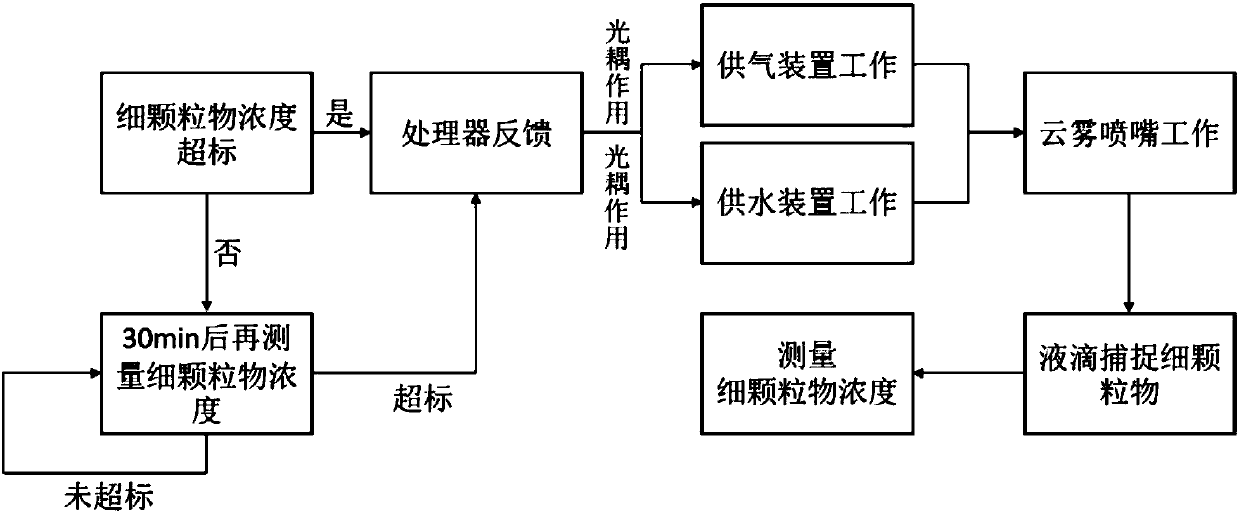

[0059] An example of the fine particle purification method of the present invention, the schematic diagram of its purification process is as follows image 3 As shown, it specifically includes the following steps:

[0060] Set the temperature of the environmental laboratory to -15°C, and the fine particle detector 1 takes a sample of the ambient air every 30 minutes to determine whether the concentration of fine particles in the sample exceeds 4mg / m 3 . If not exceeded, the fine particle detector 1 circulates the ambient air fine particle concentration value; if exceeded, the fine particle detector 1 generates a fine particle concentration signal, and transmits the fine particle concentration signal to the processor 2. The fine particle detector 1 preferably adopts a direct-reading dust detector, and the processor 2 preferably adopts a general-purpose single-chip microcomputer. Processor 2 makes feedback after receiving the signal, and controls the operation of air supply de...

Embodiment 3

[0062] An example of the fine particle purification method of the present invention, the schematic diagram of its purification process is as follows image 3 As shown, it specifically includes the following steps:

[0063] Set the temperature of the environmental laboratory to -10°C, and the fine particle detector 1 takes a sample of the ambient air every 30 minutes to determine whether the concentration of fine particles in the sample exceeds 4mg / m 3. If not exceeded, the fine particle detector 1 circulates the ambient air fine particle concentration value; if exceeded, the fine particle detector 1 generates a fine particle concentration signal and transmits the signal to the processor 2. The fine particle detector 1 preferably adopts a direct-reading dust detector, and the processor 2 preferably adopts a general-purpose single-chip microcomputer. Processor 2 makes feedback after receiving the signal, and controls the air supply device 5 to work through the action of the op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com