Polyimide precursor and polyimide made therefrom

A polyimide precursor, polyimide technology, used in synthetic resin layered products, lamination, photovoltaic power generation, etc., can solve the problems of low CTE heat resistance, transparency, difficulty in production, and difficulty in peeling , to achieve the effect of high transparency and low thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] Hereinafter, the present invention will be specifically described based on Examples and Comparative Examples. Furthermore, the present invention is not limited by these contents.

[0120] The codes and evaluation methods of materials used in Examples and Comparative Examples are shown.

[0121] (acid dianhydride)

[0122] BPDA: 3,3',4,4'-biphenyltetracarboxylic dianhydride

[0123] CBDA: 1,2,3,4-cyclobutane tetracarboxylic dianhydride

[0124] 6FDA: 4,4'-(2,2'-hexafluoroisopropylidene)diphthalic dianhydride

[0125] (diamine)

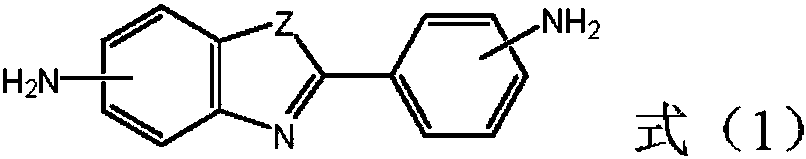

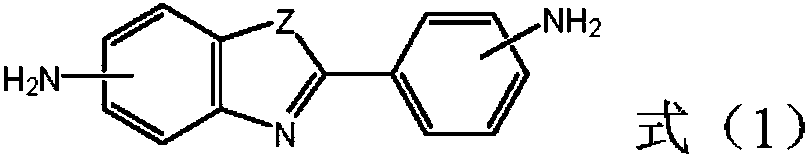

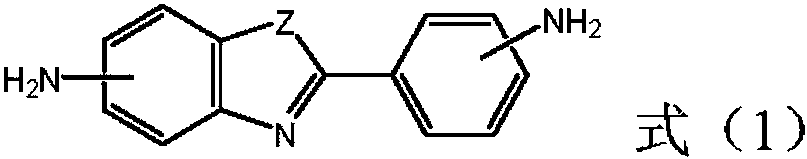

[0126] AAPBZI: 5-amino-2-(4-aminophenyl)benzimidazole

[0127] TFMB: 2,2'-bis(trifluoromethyl)benzidine

[0128] m-TB: 2,2'-dimethyl-4,4'-diaminobiphenyl

[0129] AAPBZO: 5-amino-2-(4-aminophenyl)benzoxazole

[0130] (solvent)

[0131] NMP: N-methyl-2-pyrrolidone

[0132] (Light transmittance and YI)

[0133] The light transmittance (T308, T355, T400, T430) at 308nm, 355nm, 400nm and 430nm was obtained for the polyimide film (50mm×50mm) ...

Synthetic example 1

[0149] 8.5575 g of TFMB were dissolved in 85 g of NMP in a 100 ml separable flask under nitrogen flow. Next, 0.6678 g of AAPBZI was added to the solution. After stirring for 10 minutes, 5.7757 g of CBDA was added. In addition, the molar ratio (a / b) of an acid dianhydride (a) and a diamine (b) was made into 0.990. The solution was heated at 40° C. for 10 minutes to dissolve the contents, and then, at room temperature, the solution was continuously stirred for 24 hours to carry out a polymerization reaction to obtain a high degree of polymerization polyimide precursor A (viscous without color solution).

[0150] Synthesis Example 2 to Synthesis Example 9

[0151] Except that the acid dianhydride and diamine were changed to the mass compositions shown in Table 1 and Table 2, the polyimide precursor solution was prepared in the same manner as in Synthesis Example 1 to obtain polyimide precursor B to polyimide Precursor I.

[0152] [Table 1]

[0153] Synthesis exampl...

Embodiment 1

[0157] Add the solvent NMP to the polyimide precursor solution A obtained in Synthesis Example 1, dilute it so that the viscosity becomes 4000cP, and then use a spin coater so that the thickness of the cured polyimide becomes about 13 μm It was applied on a glass substrate (E-XG manufactured by Corning, size=150 mm×150 mm, thickness=0.7 mm). Next, heating was performed at 100° C. for 15 minutes. Then, in a nitrogen atmosphere, the temperature was raised from room temperature to 300°C at a certain temperature increase rate (3°C / min), and kept at 130°C for 10 minutes in the middle, thereby forming the first polyimide layer of 150mm×150mm on the glass substrate (Polyimide A), the polyimide laminated body A was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com