Preparation method of cellulose-based foaming buffer packaging materials in BmimCl/LiOH system

A cellulose-based, cushioning packaging technology, applied in the field of cellulose materials, can solve the problems of high production cost, complicated manufacturing process, environmental pollution, etc., and achieve the effect of excellent performance and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

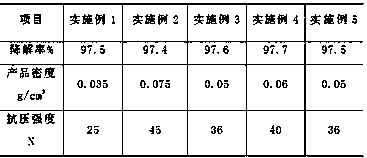

Examples

Embodiment 1

[0026] Example 1: This example provides a method for preparing a porous cellulose-based foam cushioning packaging material, and the specific steps are as follows:

[0027] (1) Vacuum drying: the microcrystalline cellulose was vacuum-dried at 45°C for 36 h;

[0028] (2) Mixing treatment: Mix 1-butyl-3-methylimidazole chloride and LiOH solution to prepare a solvent, wherein the mass fraction of 1-butyl-3-methylimidazole chloride in the solvent is 97.5 %, then add vacuum-dried microcrystalline cellulose in the solvent to obtain a mixed solution, wherein the massfraction of microcrystalline cellulose in the mixed solution is 5%;

[0029] (3) Protection treatment: Before mixing and dissolving for heat treatment, it is necessary to pass nitrogen protection to the mixed solution to prevent the oxidation of cellulose during heat treatment;

[0030] (4) Heat treatment: The mixed solution obtained after the mixed treatment in step (2) and nitrogen protection in step (3) was placed in a...

Embodiment 2

[0036] Example 2: This example provides a method for preparing a porous cellulose-based foaming cushioning packaging material. The specific steps are as follows:

[0037] (1) Vacuum drying: the microcrystalline cellulose was vacuum-dried at 45°C for 36 h;

[0038] (2) Mixing treatment: Mix 1-butyl-3-methylimidazole chloride and LiOH solution to prepare a solvent, wherein the mass fraction of 1-butyl-3-methylimidazole chloride in the solvent is 97.5 %, then add vacuum-dried microcrystalline cellulose in the solvent to obtain a mixed solution, wherein the massfraction of microcrystalline cellulose in the mixed solution is 10%;

[0039] (3) Protection treatment: Before mixing and dissolving for heat treatment, it is necessary to pass nitrogen protection to the mixed solution to prevent the oxidation of cellulose during heat treatment.

[0040] (4) Heat treatment: The mixed solution obtained after the mixed treatment in step (2) and nitrogen protection in step (3) was placed in a...

Embodiment 3

[0046] Example 3: This example provides a method for preparing a porous cellulose-based foaming cushioning packaging material, and the specific steps are as follows:

[0047] (1) Vacuum drying: the microcrystalline cellulose was vacuum-dried at 45°C for 36 h;

[0048] (2) Mixing treatment: Mix 1-butyl-3-methylimidazole chloride and LiOH solution to prepare a solvent, wherein the mass fraction of 1-butyl-3-methylimidazole chloride in the solvent is 99% %, then add vacuum-dried microcrystalline cellulose in the solvent to obtain a mixed solution, wherein the massfraction of microcrystalline cellulose in the mixed solution is 7%;

[0049] (3) Protection treatment: Before mixing and dissolving for heat treatment, it is necessary to pass nitrogen protection to the mixed solution to prevent the oxidation of cellulose during heat treatment.

[0050] (4) Heat treatment: The mixed solution obtained after the mixed treatment in step (2) and nitrogen protection in step (3) was placed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com