Matte finish-carving ink and preparation method thereof

An ink, fine carving technology, applied in the direction of ink, household appliances, applications, etc., can solve the problems of low gloss and can not meet the demand and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

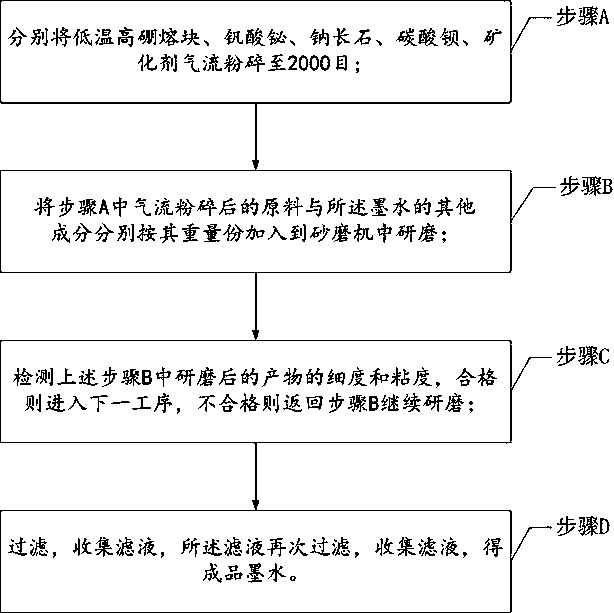

Method used

Image

Examples

Embodiment 1

[0082] The matte engraving ink, calculated in parts by weight, includes:

[0083] 15 parts of low-temperature high-boron frit,

[0084] 6 parts of bismuth vanadate,

[0085] Albite 10 parts,

[0086] Barium carbonate 5 parts,

[0087] 1 part fluorite,

[0088] 5 parts of ricinoleic acid polymer,

[0089] Fatty acid ethylhexyl ester 3 parts,

[0090] Fatty acid methyl ester 3 parts,

[0091] 45 parts of white oil.

[0092] Wherein, described albite feldspar comprises the component of following mass fraction:

[0093] Na 2 O 10~13%,

[0094] Al 2 o 3 16-20%,

[0095] SiO 2 65-70%.

[0096] The low-temperature high-boron frit includes the following components in mass fraction:

[0097] B 2 o 3 20%~40%,

[0098] SiO 2 35%~45%,

[0099] Al 2 o 3 2%~5%,

[0100] Na 2 O 10%~15%,

[0101] CaO 10% to 15%.

[0102] Described fluorspar comprises the component of following mass fraction:

[0103] CaF 2 93%~98%,

[0104] Fe2O 3 0.5~1%,

[0105] SiO ...

Embodiment 2

[0113] The matte engraving ink, calculated in parts by weight, includes:

[0114] 17 parts of low-temperature high-boron frit,

[0115] Bismuth vanadate 10 parts,

[0116] Albite 5 parts,

[0117] 8 parts of barium carbonate,

[0118] Lithium fluoride 1.5 parts,

[0119] 4 parts castor oil,

[0120] 3 parts of hydrogenated ricinoleic acid polymer,

[0121] 10 parts of diisobutyl succinate,

[0122] 55 parts of white oil.

[0123] Wherein, described albite feldspar comprises the component of following mass fraction:

[0124] Na 2 O 10~13%,

[0125] Al 2 o 3 16-20%,

[0126] SiO 2 65-70%.

[0127] The low-temperature high-boron frit includes the following components in mass fraction:

[0128] B 2 o 3 20%~40%,

[0129] SiO 2 35%~45%,

[0130] Al 2 o 3 2%~5%,

[0131] Na 2 O 10%~15%,

[0132] CaO 10% to 15%.

[0133] The preparation method of above-mentioned ink comprises the following steps:

[0134] A. Airflow pulverize low temperature high boron ...

Embodiment 3

[0140] The matte engraving ink, calculated in parts by weight, includes:

[0141] 20 parts of low-temperature high-boron frit,

[0142] Bismuth vanadate 5 parts,

[0143] Albite 7 parts,

[0144] 9 parts of barium carbonate,

[0145] Sodium fluorosilicate 2 parts,

[0146] 6 parts of hydrogenated ricinoleic acid polymer,

[0147] 3 parts fatty acid isopropyl ester,

[0148] 5 parts of diisobutyl adipate,

[0149] 40 parts of white oil.

[0150] Wherein, described albite feldspar comprises the component of following mass fraction:

[0151] Na 2 O 10~13%,

[0152] al 2 o 3 16-20%,

[0153] SiO 2 65-70%.

[0154] The low-temperature high-boron frit includes the following components in mass fraction:

[0155] B 2 o 3 20%~40%,

[0156] SiO 2 35%~45%,

[0157] al 2 o 3 2%~5%,

[0158] Na 2 O 10%~15%,

[0159] CaO 10% to 15%.

[0160] The preparation method of above-mentioned ink comprises the following steps:

[0161] A. The low-temperature high-boron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com