Cement-bentonite vertical antifouling separating wall structure and method

A technology of bentonite and partition wall, which is applied in the direction of infrastructure engineering, sheet pile wall, protection device, etc., can solve the problems affecting the integrity of vertical anti-fouling partition wall and long-term service performance, impermeability, adsorption properties are inferior, It is difficult to achieve problems such as underground pollution prevention and control, and achieve the effects of strong deformation resistance, high shear strength and small working surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

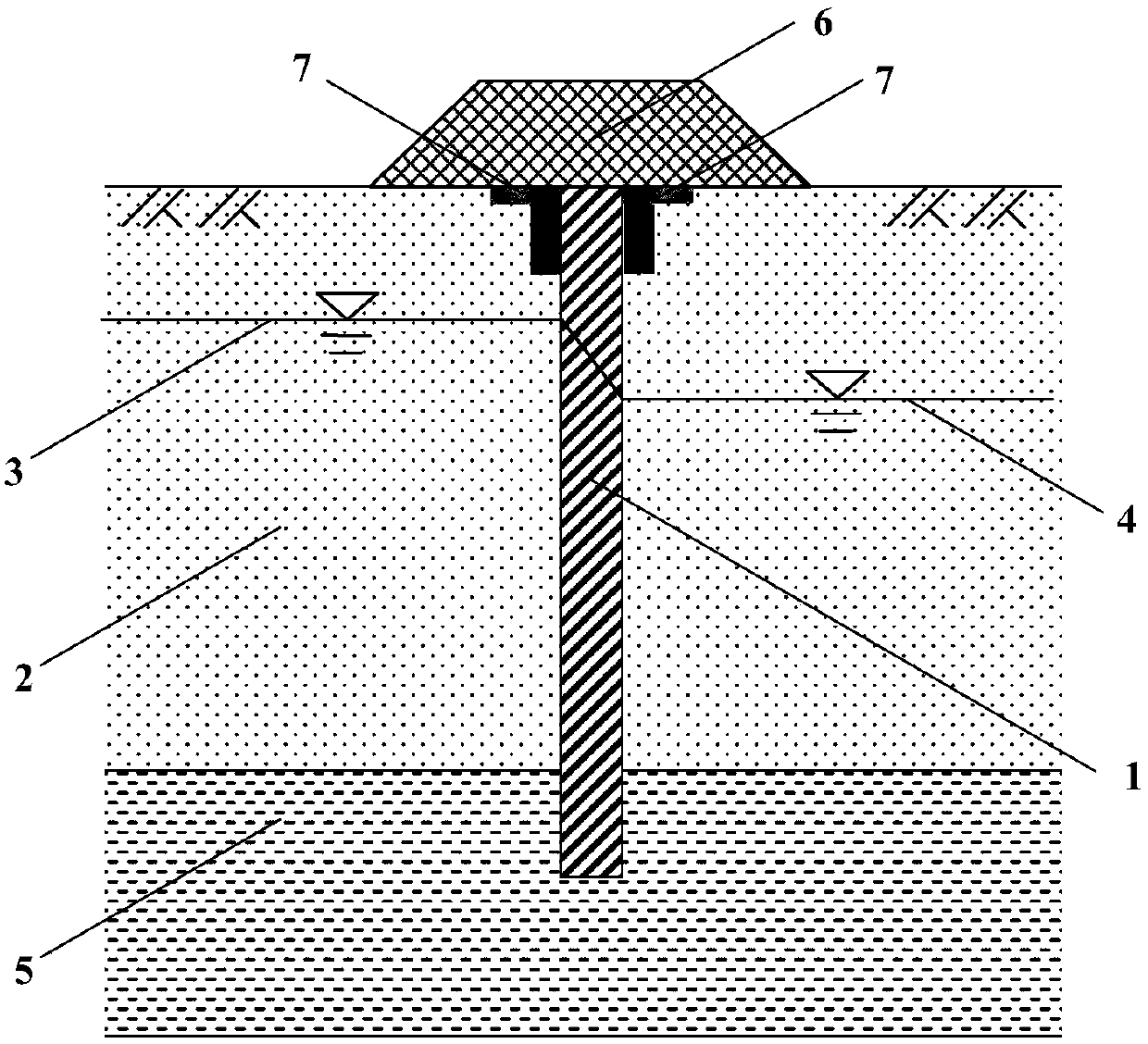

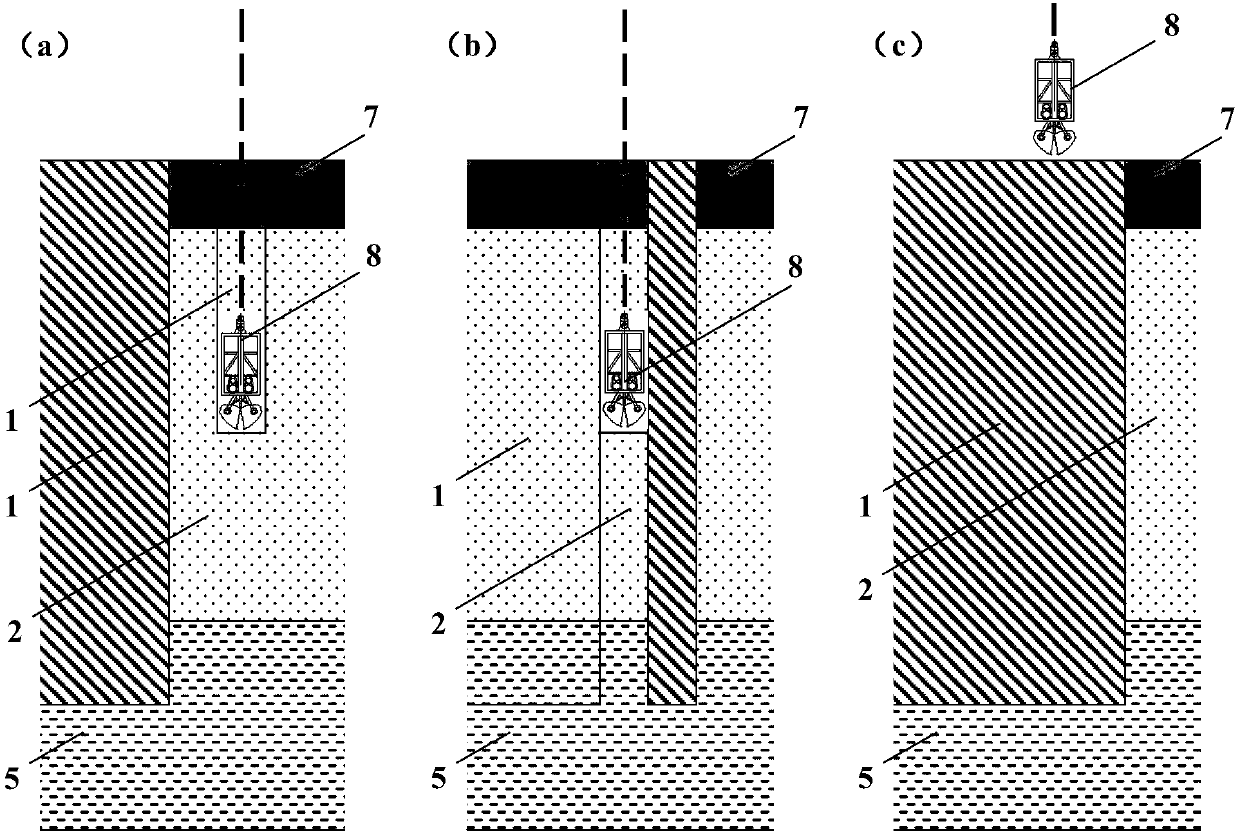

Method used

Image

Examples

experiment example 1

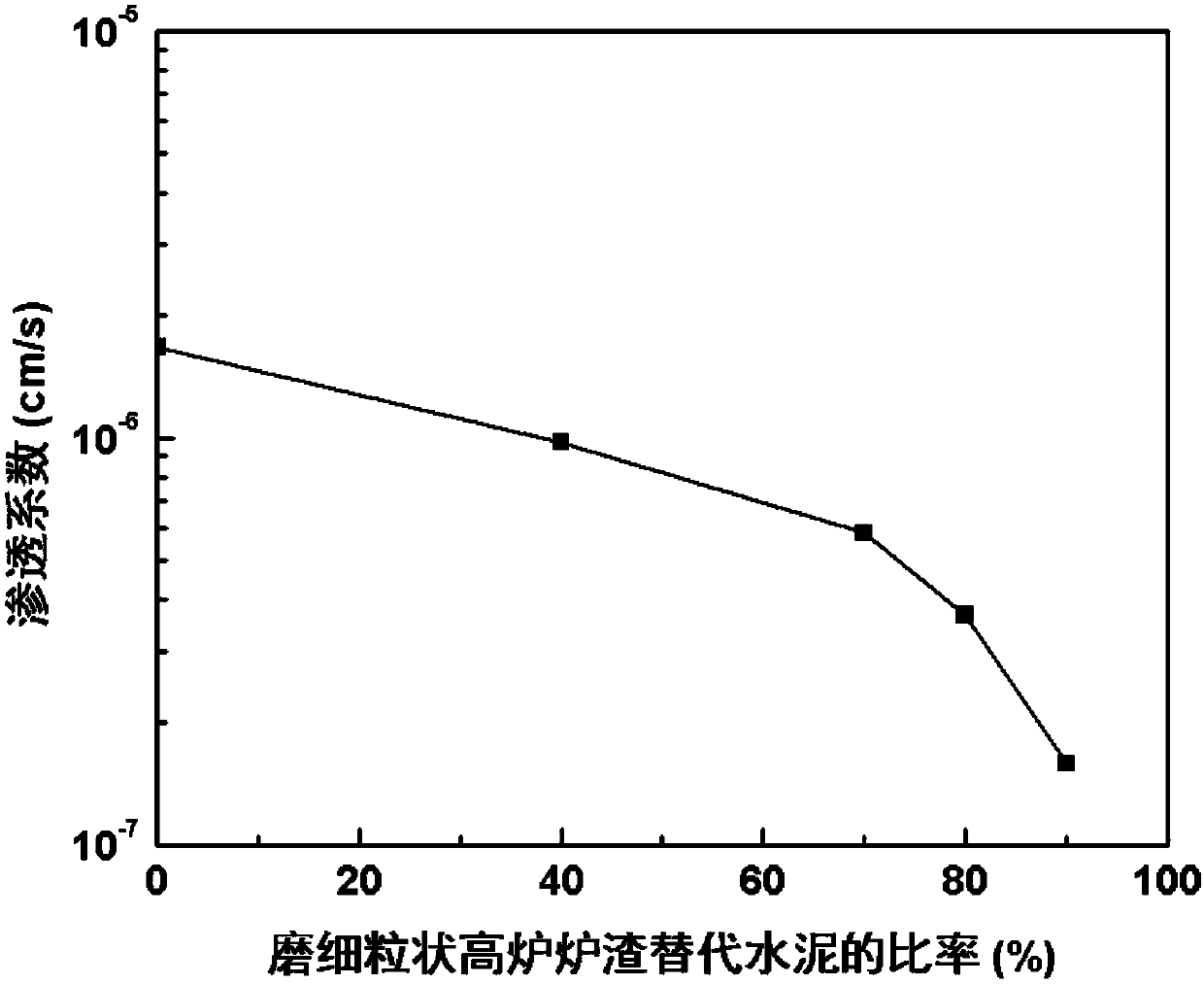

[0053] The cement-bentonite of this experimental example is specifically the use of C42.5 ordinary Portland cement (produced by Hangzhou Qianchao Cement Co., Ltd.), a certain bentonite in Shandong and finely ground blast furnace slag (produced by Yuanheng Water Purification Material Factory in Gongyi City) and tap water. formulated. Among them, the sum of the mass of ground granular blast furnace slag and cement is 20% of the total mass of cement-bentonite, and the mass of ground granular blast furnace slag is 0%, 40%, 70%, or 0% of the sum of the mass of ground granular blast furnace slag and cement 80% and 90%; the mass of bentonite mud is 80% of the total mass of cement-bentonite, and the mass of bentonite is 5% of the mass of bentonite mud. After the cement-bentonite sample was prepared, it was cured in a water bath at a temperature of 20° for 28 days, then consolidated under a pressure of 100kPa, and then tested for the permeability coefficient under the condition of a hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com