Device and method for testing in-situ gas chromatography generated inside lithium ion battery

A lithium-ion battery and gas chromatography technology, which is applied in the field of in-situ gas chromatography testing devices for gases, can solve problems such as difficult electrode potential calibration, gas volume cannot be quantified and analyzed, and the specific source of gas cannot be determined, etc., to achieve data Accurate, easy to detect the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

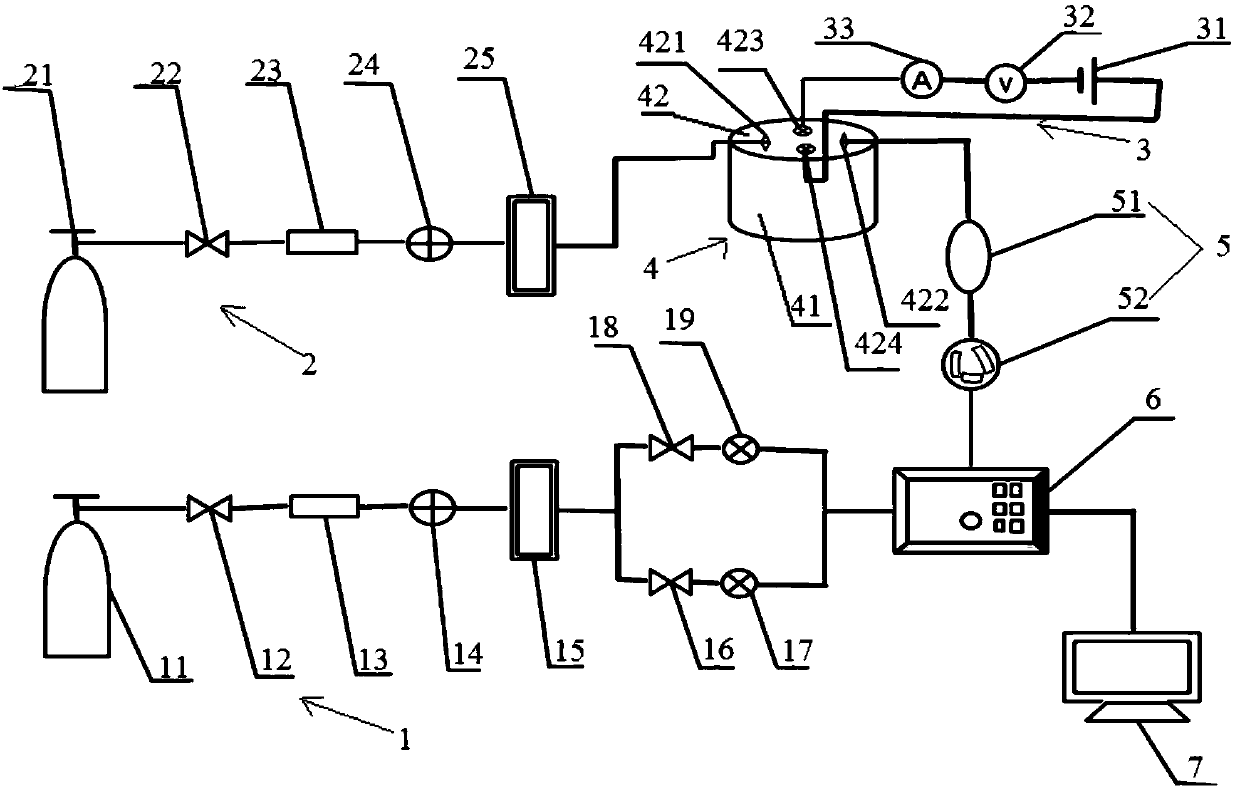

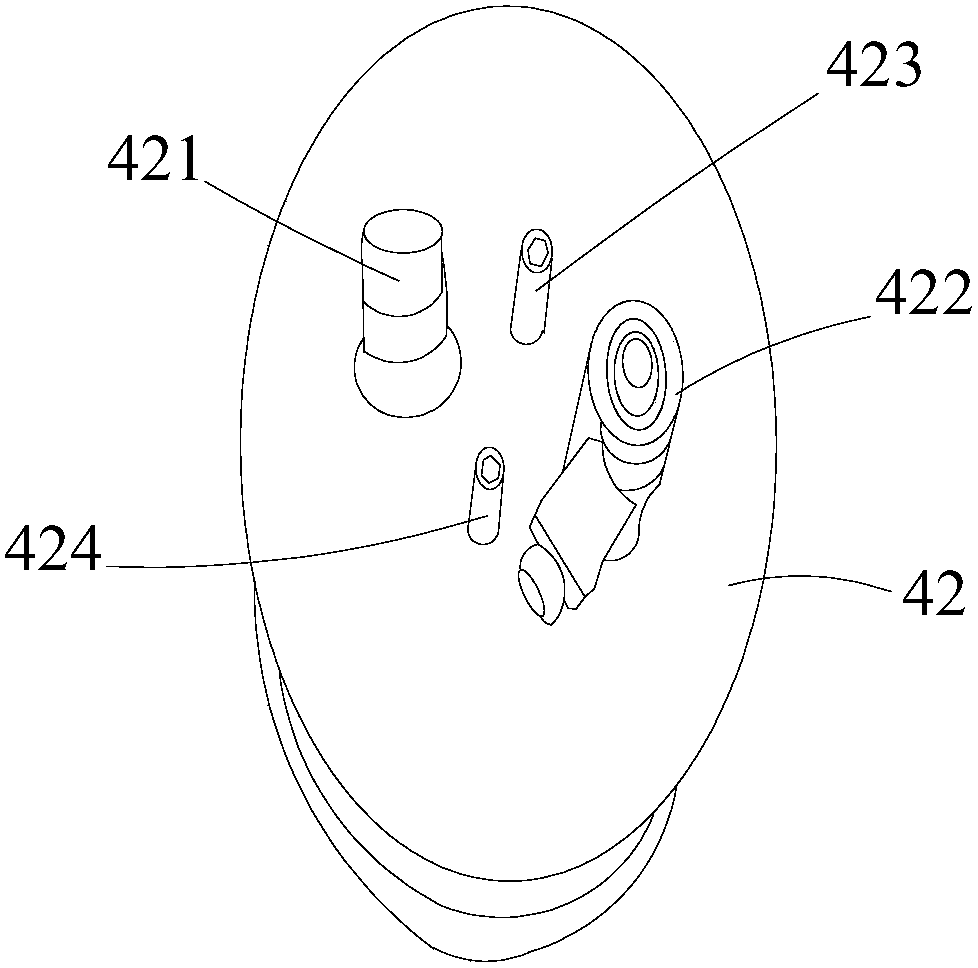

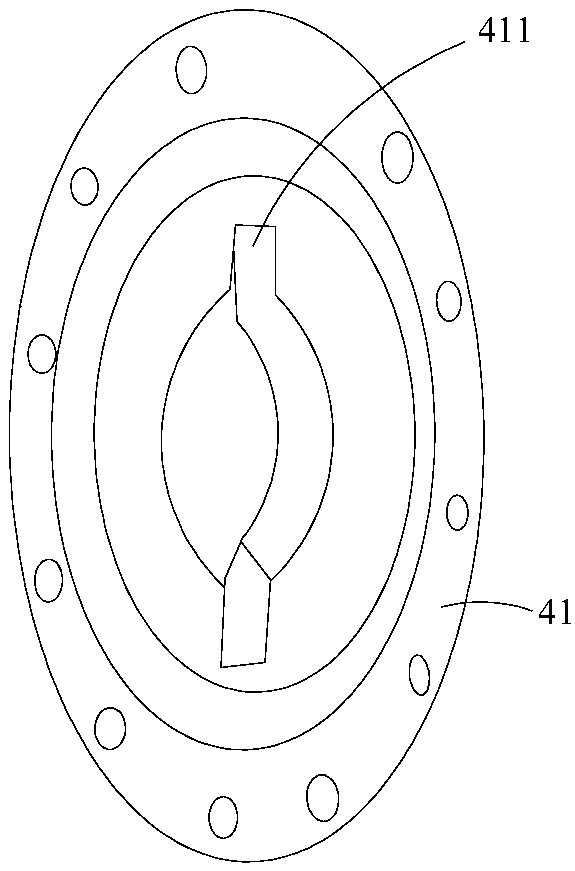

[0033] The invention provides an in-situ gas chromatographic test device for gas generated inside a lithium-ion battery, comprising a carrier gas supply unit 1, an inert gas supply unit 2, a power supply unit 3, a reaction unit 4 containing lithium-ion cells, Gas collection unit 5, gas chromatograph 6 and data acquisition and processing unit 7, carrier gas supply unit 1 is connected to gas chromatograph 6, inert gas supply unit 2 is connected to reaction unit 4, power supply unit 3 is connected to reaction unit 4 The inlet end of the gas collection unit 5 is connected to the reaction unit 4, the outlet end of the gas collection unit 5 is connected to the gas chromatograph 6, the gas chromatograph 6, the power supply unit 3, and the reaction unit 4 are all connected to the data acquisition and processing unit 7. Carrier gas supply unit 1 provides carrier gas for gas chromatograph 6, and inert gas supply unit 2 provides inert gas for reaction unit 4. In the present invention, the...

Embodiment 2

[0059] This embodiment provides a method of using the device and method of Embodiment 1 to conduct online testing of the gas generated during the formation of square lithium-ion cells:

[0060] Preparing lithium-ion batteries in a square shape: through stirring, coating, cold pressing of pole pieces, winding, packaging, and baking to remove moisture, the square batteries to be injected are obtained, and the batteries are placed in a completely dry reaction kettle. The liquid is injected in a glove box filled with argon gas. After the liquid injection is completed, the reactor is sealed with six sets of symmetrical screws and sealing rings, and a layer of vacuum grease is applied to the connection to ensure absolute sealing.

[0061] Then, the formation is carried out. After the battery cell after the liquid injection is left to stand for a period of time, it is formed, and the gas generated during the formation process is tested online. The positive electrode material of the s...

Embodiment 3

[0066] This embodiment provides a method of using the device and method of Embodiment 1 to conduct online testing of the gas generated during the charging and discharging process of cylindrical cells with different moisture contents:

[0067] Dry the coated positive and negative pole pieces at 120°C for 4h, 8h, and 16h, respectively. Ultrasonic spot welding machine is used to weld the tabs. The negative electrode uses copper foil as the current collector, the positive electrode uses aluminum foil as the current collector, the positive electrode uses aluminum sheet, and the negative electrode uses nickel sheet as the tab. Winding and fixing with insulating tape to obtain a cylindrical lithium-ion cell, put the cell into a vacuum oven, and dry at 80±5°C for 12 hours. Place the prepared cell and reactor in a glove box filled with argon to inject the electrolyte, and then fix and seal them with screws and vacuum grease. In order to prove that the test electrolytic cell is close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com