Preparation method of ethanol oxidation catalyst with high-efficient electron transporting structure

An electron transport and ethanol oxidation technology, applied in structural parts, electrochemical generators, circuits, etc., can solve the problems of easy corrosion and oxidation of carbon carriers, high overpotential of cathode catalysts, easy poisoning of anode catalysts, etc., to reduce commercialization Cost, low onset potential, and the effect of improving electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Specific steps are as follows:

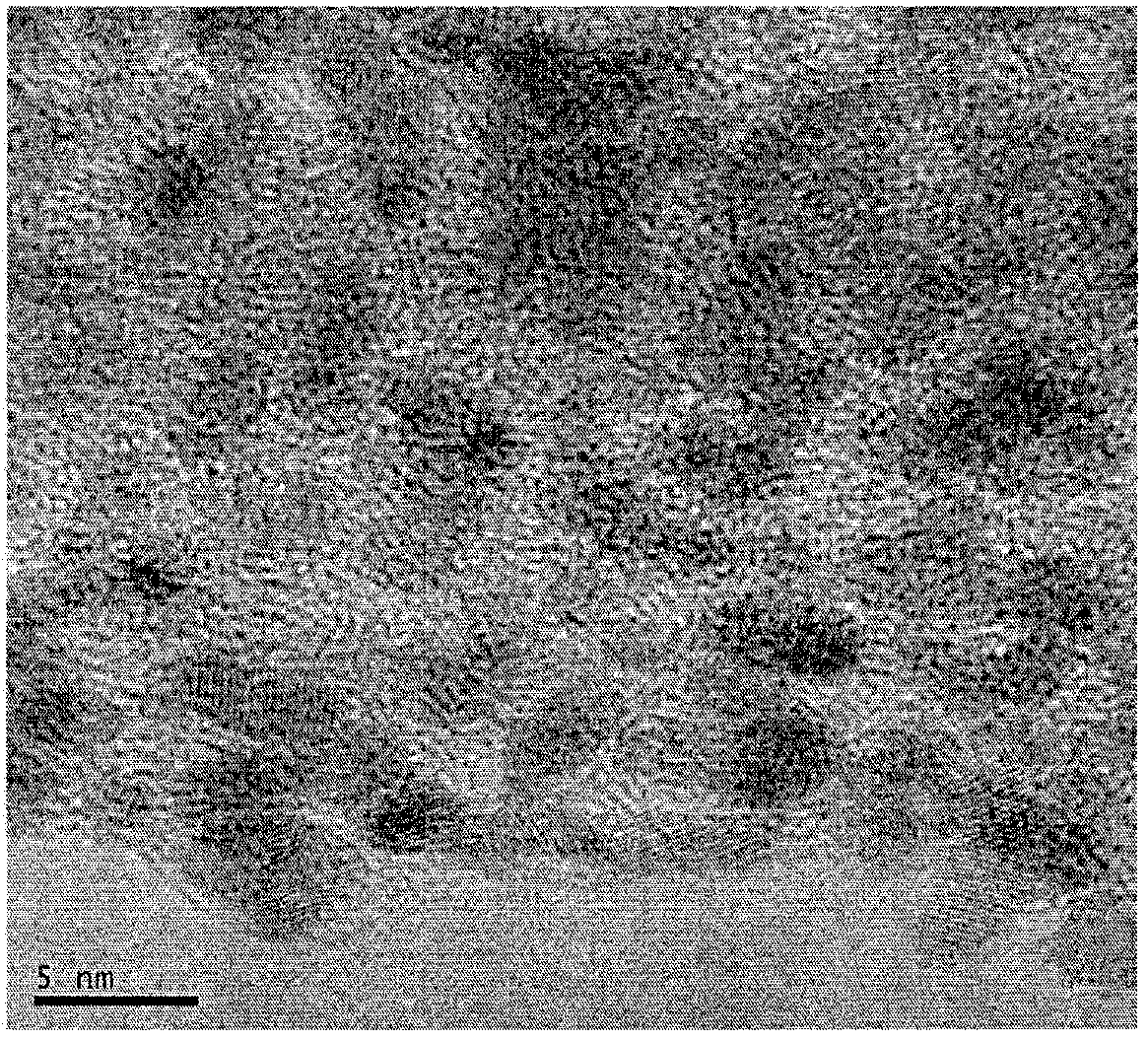

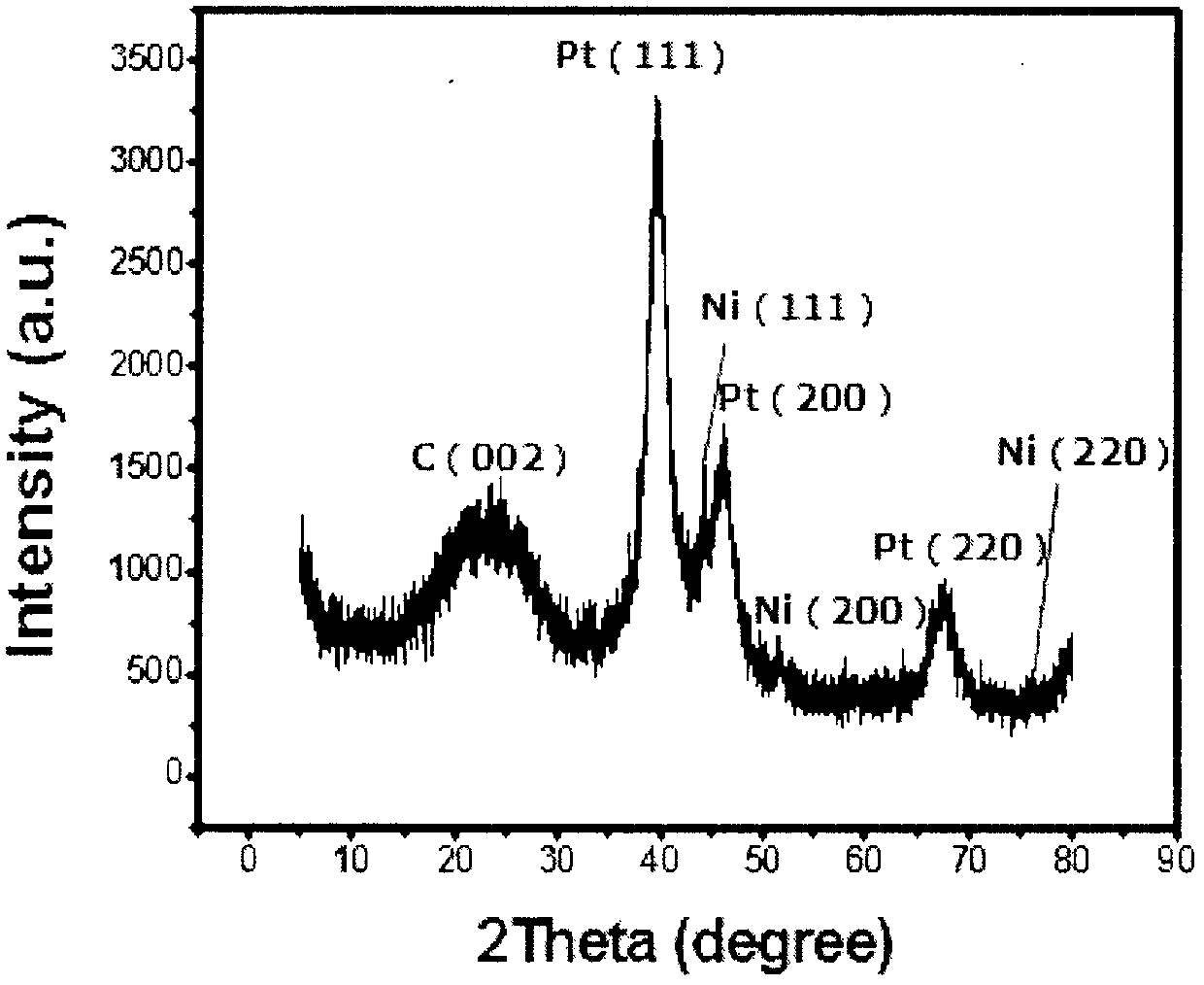

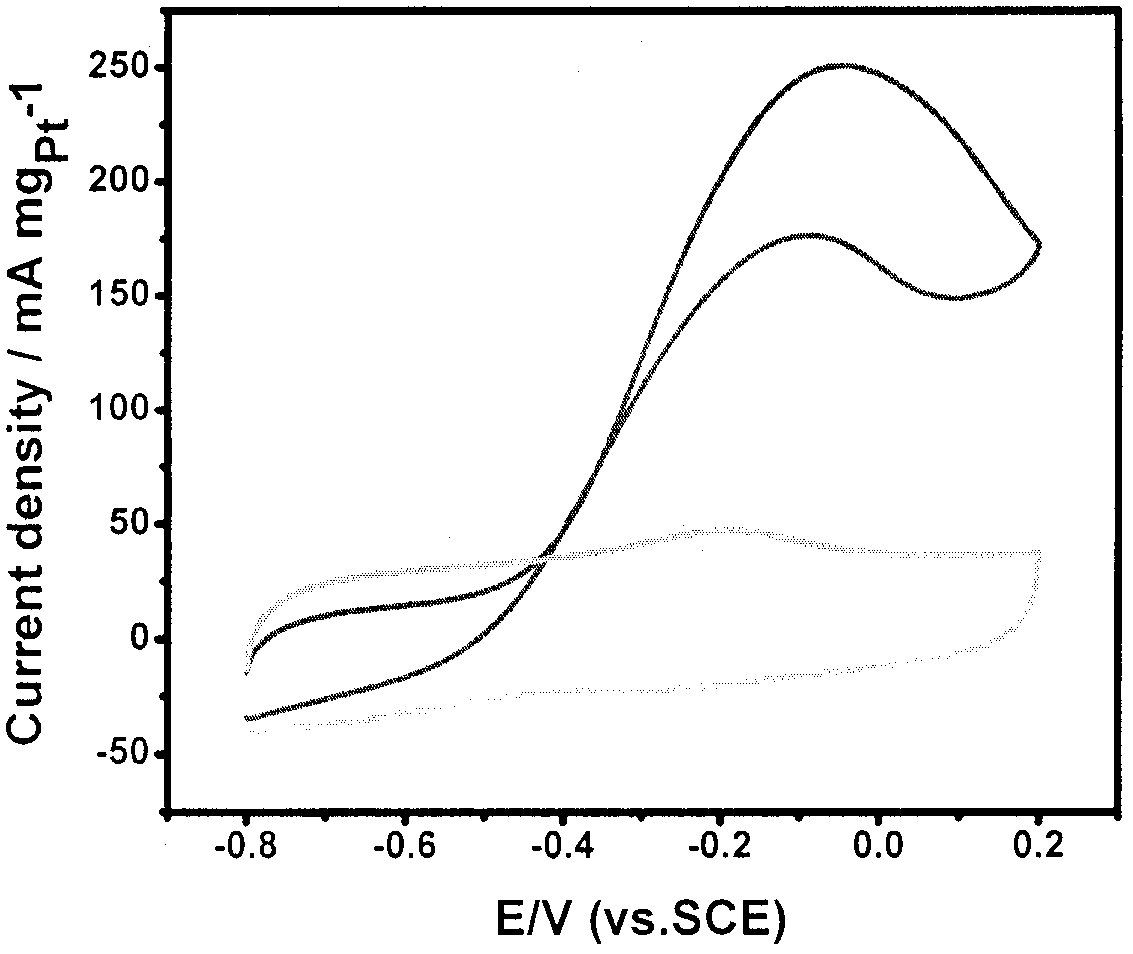

[0016] Weigh 1.5g of glucose, 0.2g of nickel chloride and 0.5g of urea, mix and dissolve in 30ml of distilled water, and dry at 100°C for 12h; the obtained solid sample is calcined at 3°C / min to 800°C under a nitrogen atmosphere, and kept for 2h. To obtain a nitrogen-doped nickel / carbon solid sample; take 50 mg of the above sample and disperse it in 20 mL of ethylene glycol solution, add 1.11 ml of chloroplatinic acid solution with a mass concentration of 7.91 mg / ml after ultrasonication for two hours, and continue ultrasonication for two hours , the resulting mixed solution was moved to a three-necked flask, nitrogen gas was continuously introduced, and reacted in a flowing oil bath at a temperature of 130°C for 3 hours. After natural cooling, it was washed with distilled water and ethanol for 5 times, and then placed in a dry box. Dry at 100°C for 10 hours to obtain a nitrogen-doped platinum-nickel / carbon catalyst. The morphology of t...

Embodiment 2

[0018] Same as Example 1, except that the consumption of chloroplatinic acid solution was changed to 0.74 mL. The prepared catalyst particles are unevenly dispersed and the current density is low.

Embodiment 3

[0020] Same as Example 1, except that the consumption of chloroplatinic acid solution was changed to 2.22mL. The prepared catalyst has obvious agglomeration phenomenon and low current density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com