Titanium-doped indium zinc sulfide flower-shaped microspheres as well as preparation method and application thereof

An indium zinc sulfide and titanium doping technology is applied in the field of catalysis, which can solve the problems of photocorrosion, affecting the hydrogen production rate, etc., and achieve the effects of improving photocorrosion, improving the ability of photocatalytic hydrogen production, and simple experimental equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

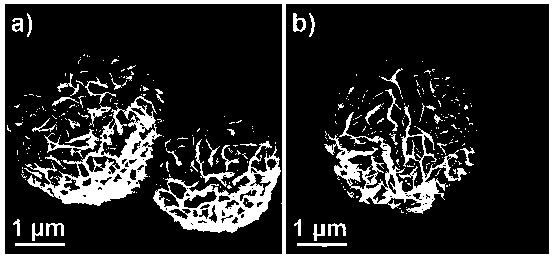

[0032] Weigh 1mmol of zinc chloride, 2mmol of indium chloride, and 5mmol of thioacetamide, add 80mL of deionized water and stir evenly, transfer to a polytetrafluoroethylene tank, put it into a high-pressure reactor, and put it in a blast drying oven at 80°C Thermal reaction for 12 hours; after the hydrothermal treatment, pour off the supernatant, take the orange-yellow precipitate at the bottom, wash it three times with deionized water, and then dry it in a blast drying oven at 60°C for 8 hours to obtain indium sulfide spangles with a flower-like structure shaped microspheres.

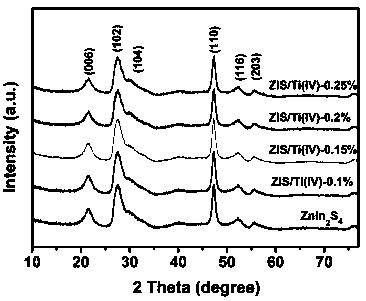

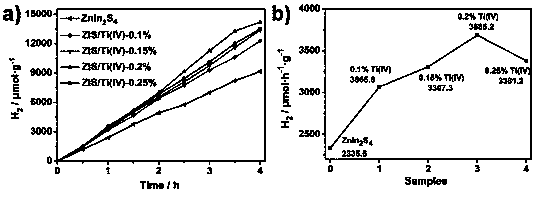

[0033] Take 10mL of titanium sulfate solution with a concentration of 0.1g / L, add 1g of indium zinc sulfide powder, and heat on a heating platform at 30°C for 3 hours while stirring; centrifuge the mixed solution, remove the lower layer of precipitate, wash it with water three times, and place it in a blast drying oven Dry at 60°C to obtain 0.1% titanium-doped indium sulfide spangle microsphere compos...

Embodiment 2

[0035] Weigh 1mmol of zinc chloride, 2mmol of indium chloride, and 5mmol of thioacetamide, add 80mL of deionized water and stir evenly, transfer to a polytetrafluoroethylene tank, put it into a high-pressure reactor, and put it in a blast drying oven at 80°C Thermal reaction for 10 hours; after the hydrothermal treatment, pour off the supernatant, take the orange-yellow precipitate at the bottom, wash it three times with deionized water, and dry it in a blast drying oven at 60°C for 8 hours to obtain indium sulfide spangles with a flower-like structure shaped microspheres.

[0036] Take 10mL of titanium sulfate solution with a concentration of 0.15g / L, add 1g of indium zinc sulfide powder, and heat it on a heating platform at 80°C for 1 hour while stirring; centrifuge the mixed solution, remove the lower layer and wash it with water for three times, then place it in a blast drying oven Dry at 60°C to obtain 0.15% titanium-doped indium sulfide spangle microsphere composite phot...

Embodiment 3

[0038] Weigh 1mmol of zinc nitrate, 2mmol of indium chloride, and 5mmol of thioacetamide, add 80mL of deionized water and stir evenly, transfer to a polytetrafluoroethylene tank, put it into a high-pressure reactor, and heat it in a blast drying oven at 80°C React for 12 hours; after the hydrothermal treatment, pour off the supernatant, take the orange-yellow precipitate at the bottom, wash it three times with deionized water, and dry it in a blast drying oven at 60°C for 10 hours to obtain a flower-like indium sulfide spangle Microspheres.

[0039] Take 10mL of titanium sulfate solution with a concentration of 0.2g / L, add 1g of indium zinc sulfide powder, and heat it on a heating platform at 150°C for 0.25 hours while stirring; centrifuge the mixed solution, remove the lower layer and wash it with water for three times, then place it in a blast drying oven Dry at 60°C to obtain 0.2% titanium-doped indium sulfide spangle microsphere composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com